Non-destructive transfer droplet surface and preparation method and non-destructive transfer droplet method

A droplet, substrate surface technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical/physical-chemical processes using energy, etc., can solve surface pollution, energy waste, and inability to achieve droplets Free grab and release problems, to achieve the effect of improving surface adhesion and non-destructive transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

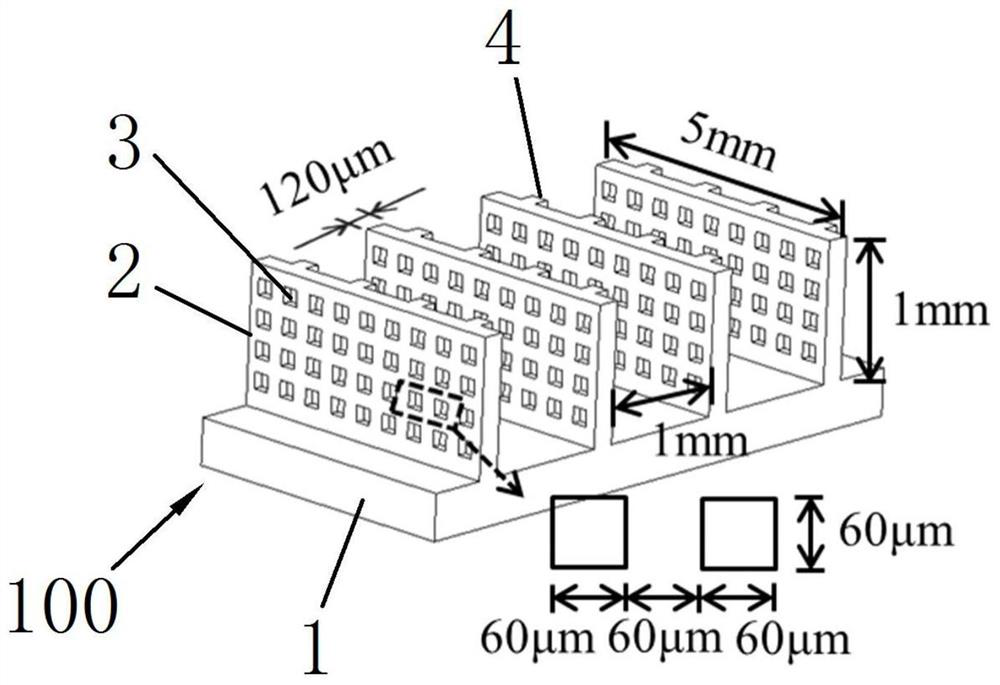

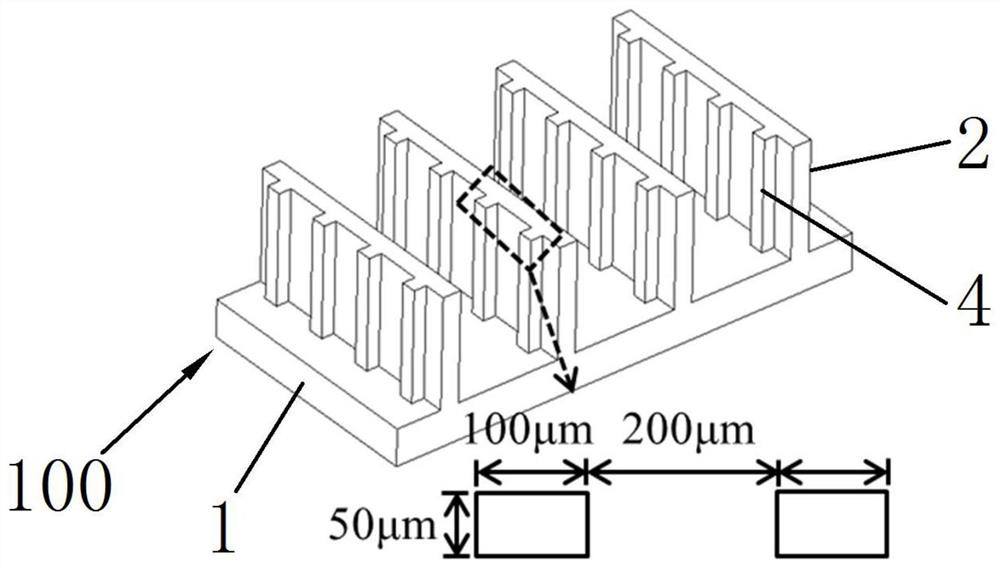

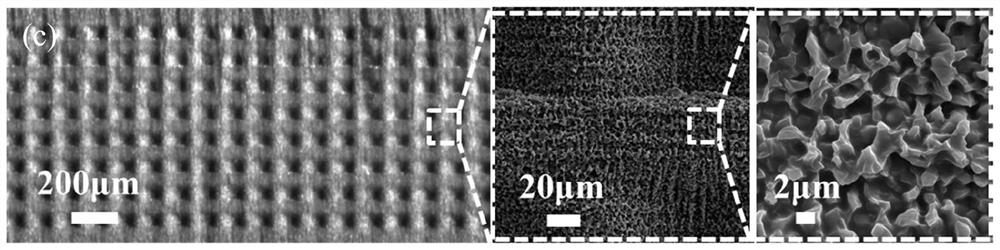

[0049] like Figure 1-5 As shown, the present embodiment provides a non-destructive transfer droplet surface 100, including a substrate 1, a plurality of microplates 2 are arranged at intervals on the surface of the substrate 1, and a plurality of grooves 3 are arranged on the same side surface of each microplate 2 , the other side surface is provided with a plurality of protrusions 4, and one end of each protrusion 4 extends to the top surface of the micro-plate 2 where it is located, and each micro-plate 2 is an elastic micro-plate, and each micro-plate 2 is externally applied Under the action of a magnetic field, it can swing synchronously between the first position and the second position. The first position is the position where the microplate 2 is perpendicular to the surface of the substrate 1. The second position is that the microplate 2 swings from the first position to the groove. position at the surface.

[0050] When in use, the surface 100 of the non-destructivel...

Embodiment 2

[0075]This embodiment provides a non-destructive transfer droplet surface 100. The difference from Embodiment 1 is that the size of the microplate 2 is length×thickness×height=5mm×0.12mm×0.5mm. The spacing is 0.5 mm. When the droplet is captured, the contact area between the droplet and the surface can be increased due to the reduction of the distance between two adjacent microplates, so that a larger volume of droplet can be captured. Figure 15 The process of grabbing and releasing 20 μL water droplets on the surface of this example is shown, Figure 15 (a) shows that water droplets can initially contact 6 microplates, compared to Figure 13 The two plates in (a) increase the volume of droplets that can be grasped.

[0076] Depend on Figure 13 and Figure 15 It can be seen that during the release process, the water droplets are first pinned on the top of the leftmost microplate, and then gradually break away from the right microplate, until finally the water droplet fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com