Processing method for eliminating color difference of nickel and gold layers in nickel and gold plating process

A processing method and nickel-gold plating technology, which is applied in the field of nickel-gold plating, can solve problems such as poor color difference, fogging, and blackening of the nickel-gold layer on the surface of the nickel-gold layer, so as to eliminate quality defects, eliminate surface color difference, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

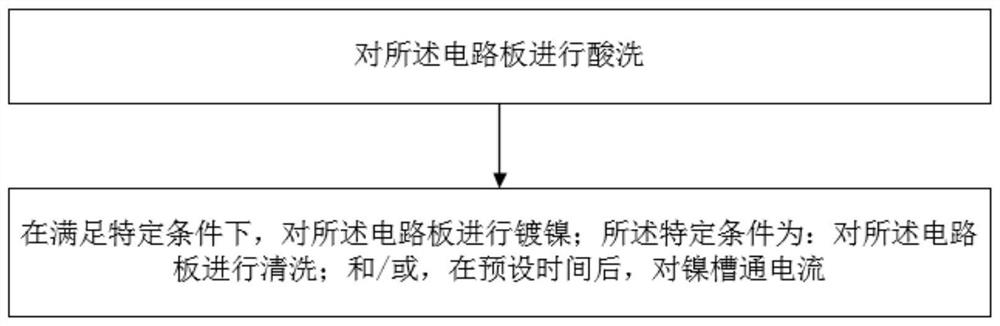

[0061] The degreasing agent degreases the surface of the circuit board;

[0062] Clean the residue on the surface of the circuit board with tap water, and wash it twice;

[0063] Soak the circuit board in the micro-etching solution to slightly corrode the surface of the circuit board;

[0064] Clean the residue on the surface of the circuit board with tap water, and wash it twice;

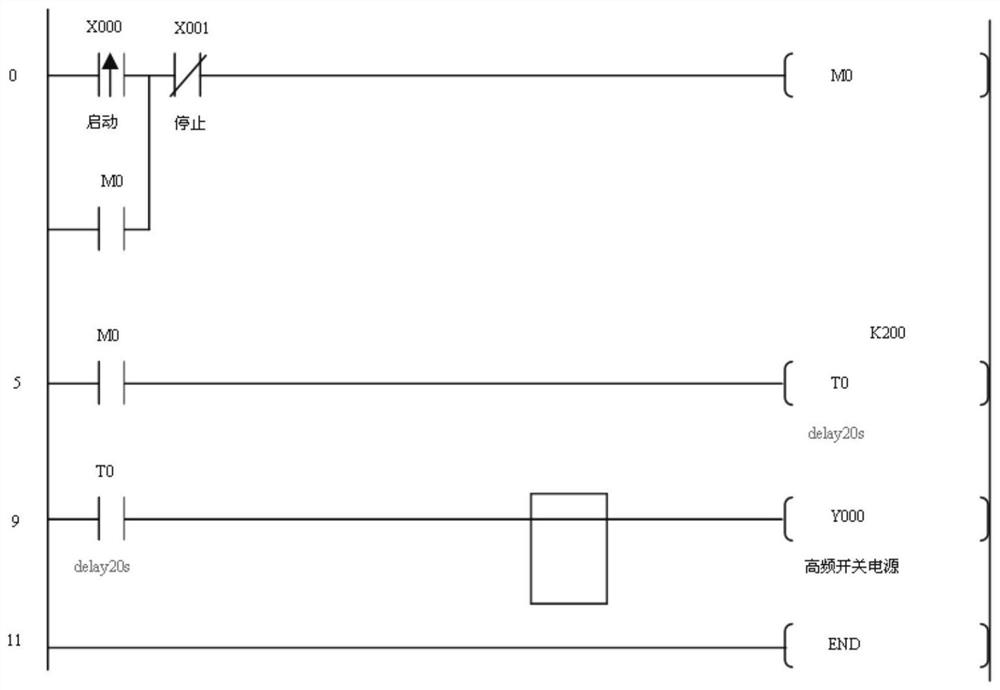

[0065] Pickling the circuit board;

[0066] Cleaning the circuit board with a deionized aqueous solution to wash away the acid solution on the circuit board;

[0067] After a delay of 20 seconds, pass current to the nickel tank and nickel-plate the circuit board;

[0068] Clean the residue on the surface of the circuit board with tap water, and wash it twice;

[0069] Soak the circuit board in the micro-etching solution to slightly corrode the surface of the circuit board;

[0070] Clean the residue on the surface of the circuit board with tap water, and wash it twice;

[0071] Pickling the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com