Relay with safety device

A safety device and relay technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information and other directions, can solve the problems of cracking, thinning, and easy damage to the electromagnet core and armature, so as to prolong the service life, save costs, and avoid replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

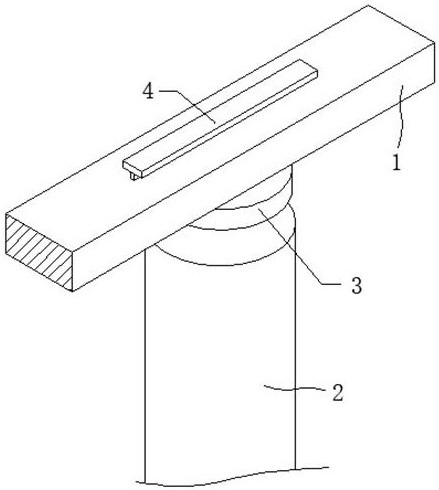

[0031] like Figure 1 to 3 As shown, a relay having a safety device provided by the present invention, including the armature 1 and the electromagnetic iron core 2, in an instantaneous moment, the electric arc is generated, and the melting point of the high temperature spacer 3 is high, so that the high temperature gasket 3 There is no deformation due to the high temperature generated by the arc, avoiding the direct hitting of the electric or high-temperature gasket 3, so that the high-temperature gasket 3 is damaged, extend the service life of high temperature gasket 3, to avoid the armature 1 and electromagnetic iron core 2 collision.

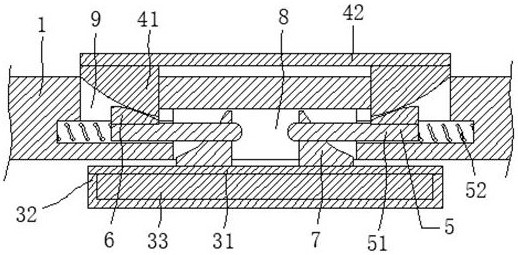

[0032] Among them, if figure 2 with image 3 As shown, the ceramic sheet 31, the carbon fiber cloth 32 and the polytetrafluoroethylene sheet 33 are high temperature resistant materials, and the high temperature produced by the arc does not affect the ceramic sheet 31, the carbon fiber cloth 32, and the polytetrafluoroethylene sheet 33, while The ce...

Embodiment 2

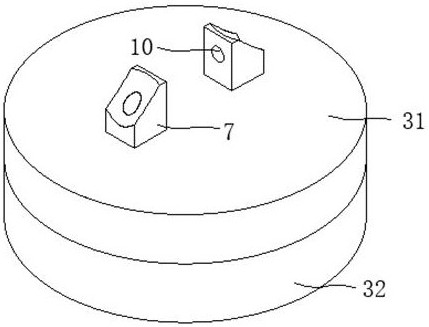

[0034] like Figures 2 to 6 As shown, the locking member 5 is provided in the armature 1 to fix the high temperature spacer 3, sliding through the sliding slot 11 through the sliding rod 51, lock the slider 51 to lock or relieve the lock lock block 7, when the card block 7 When the groove 8 is inserted, the slider 51 is inserted into the through hole 10, so that the high temperature spacer 3 can be mounted on the armature 1, and when the high temperature spacer 3 is damaged, the slider 51 moves to the spring 52, And replace the new high temperature sensing spacer 3, under the spring 52 elastic action, the slider 51 is inserted into the through hole 10 of the new high temperature gasket 3.

Embodiment 3

[0036] Further, such as figure 2 , Figure 4 , Figure 5 with Image 6 As shown, the driving member 4 is provided in the armature 1 to quickly remove the high temperature spacer 3, by applying a pressure on the active sheet 42, so that the shift block 41 slides in the card slot 9, and transmitted to the power block 6. On, the two sides of the shroud block 41 and the force block 6 are in the convex curve surface such that the two resilient blocks 6 are driven by the two slide rods 51, respectively, to keep the slider 51 from pass The holes 10 are detached, and the locking resistant high temperature gasket 3 is released.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com