Printing machine pressure adjusting device and control method thereof

A technology of pressure regulation and control method, which is applied in the direction of printing presses, rotary printing presses, general parts of printing machinery, etc. It can solve the problems of inability to realize digital formula management, inability to realize digital position storage and memory, and achieve convenient and fast pressure adjustment, Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

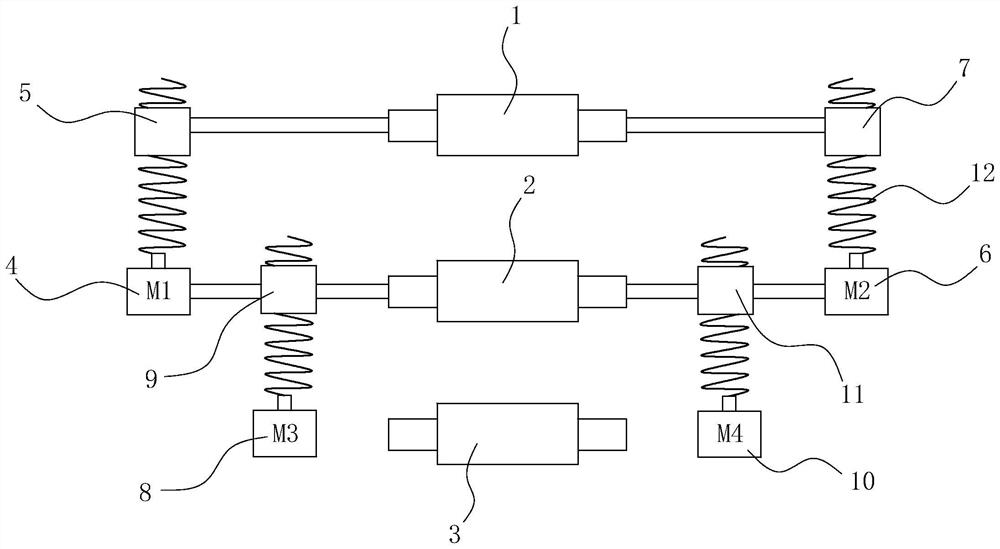

[0035] Such as figure 1 As shown, a pressure regulating device for printing presses includes an anigraph roll, a plate roll and a printing roll arranged in parallel, the plate roll is located between the screen roll and the printing roll, between the screen roll and the plate roll and between the plate roll and the plate roll An adjustment mechanism for adjusting the distance between the rollers is provided respectively, and the adjustment mechanism is electrically connected with a control system for inputting control commands.

[0036] Such as figure 1 As shown, there are four adjustment mechanisms, and the adjustment mechanisms are composed of a servo motor, a lead screw connected to the output shaft of the servo motor, and a thread sleeve fitted on the lead screw. Wherein, a first servo motor and a second servo motor are respectively installed at both ends of the plate roller, and a first wire sleeve and a second wire sleeve matched with the first servo motor and the secon...

Embodiment 2

[0038] The control method of the printing press pressure regulating device in the first embodiment includes the following steps:

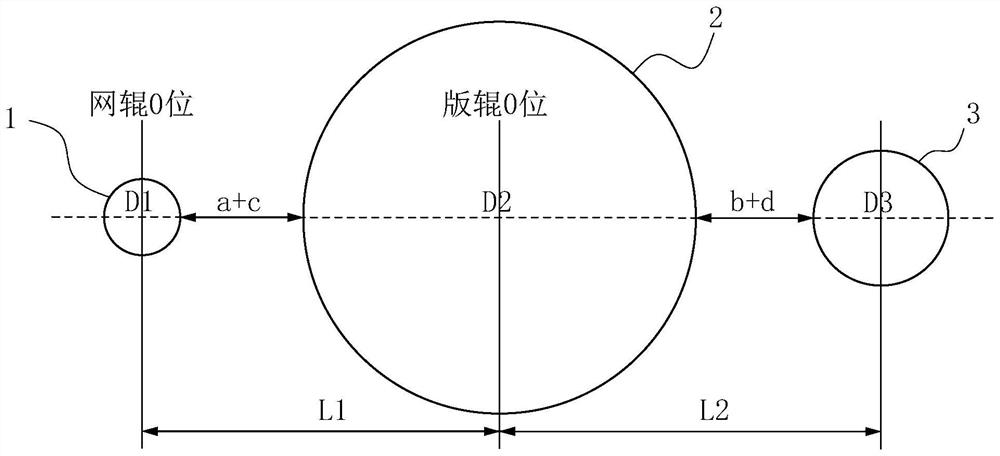

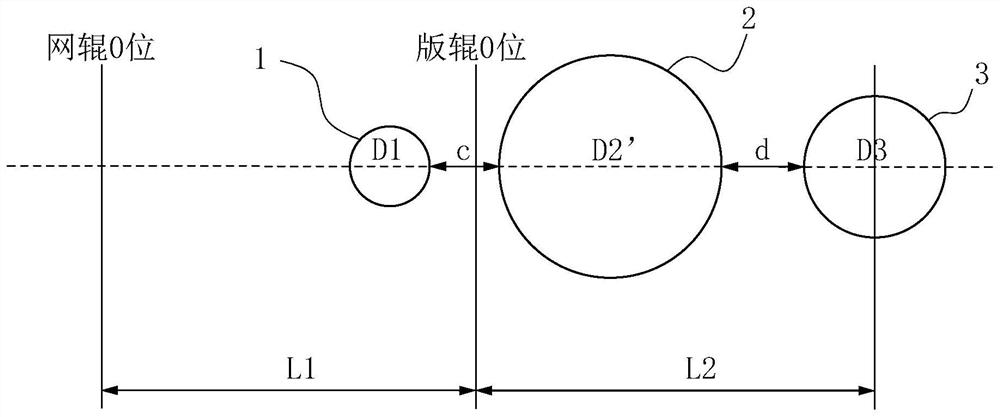

[0039] Step A1, whether the control system inputs a slide-out command, if input, the adjustment mechanism returns to zero; if not input, perform step A2; wherein, the zero position of the adjustment mechanism is determined by the control system according to the length of the lead screw, the screen roller, the printing roller, the maximum Calculated from the roll diameter or the diameter of the smallest roll.

[0040] Step A2, whether the control system inputs a slide-in command, if so, the first servo motor and the second servo motor drive the moving distance S1 of the net roll to enter the net roll off-press position, and the third servo motor and the fourth servo motor drive the moving distance of the plate roll S2 enters the release position of the plate roller, and then executes steps A3 and A6; if not input, the adjustment mechanism remains at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com