Directional development method for low-quality coal flotation collecting agent

A low-quality coal and collector technology, applied in flotation, solid separation, solid waste removal, etc., can solve natural pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

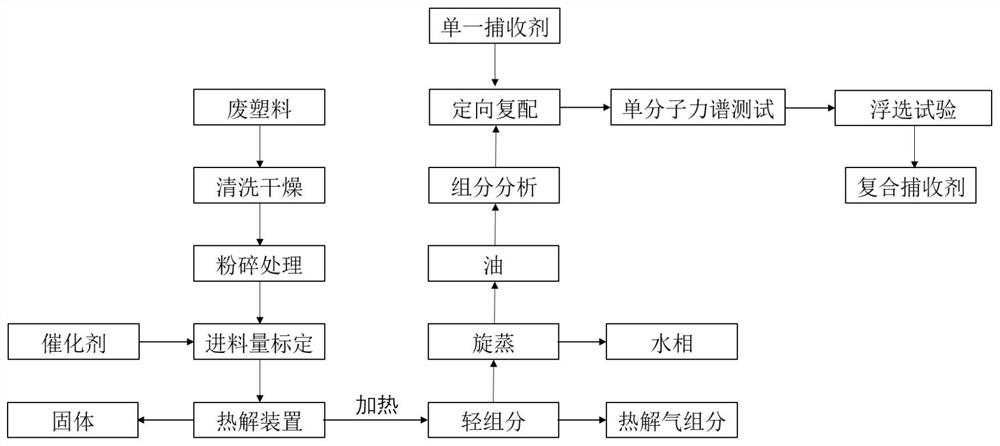

Method used

Image

Examples

Embodiment 1

[0040] Collect polyethylene terephthalate (PET) as the raw material, wash and dry it and crush it to below 40 mesh as the pyrolysis raw material, select HZSM-5 and NiO as the catalyst, calibrate and adjust the PET unit in the falling bed reactor Falling mass within a certain time, select 500°C as the reaction temperature, select N 2 For protective gas. The solid semi-coke components produced after the pyrolysis reaction are collected and used as industrial raw materials. When the light components escape from the reactor and enter the pipeline, the pipeline needs to be reheated to 400°C to prevent small molecules from repolymerizing and blocking the pipeline. The light component realizes the separation of oil and gas through condensation, and the gas is used as a chemical raw material after separation and purification, and dichloromethane is used as a solvent to mix with oil and then purified by rotary evaporation. Component analysis of the purified oil shows that the contents...

Embodiment 2

[0042] Collect polyethylene (PE) and biomass straw as raw materials, the blending mass ratio is 2:1, after cleaning and drying, they are crushed to less than 20mm as pyrolysis raw materials, and SiO with better effect is selected 2 -Al 2 o 3 As a catalyst, calibrate and adjust the falling weight of PET per unit time in a stirred reactor, select 440°C as the reaction temperature, and select N 2 For protective gas. The solid semi-coke components produced after the pyrolysis reaction are collected and used as industrial raw materials. When the light components escape from the reactor and enter the pipeline, the pipeline needs to be reheated to 380°C to prevent small molecules from repolymerizing and blocking the pipeline. The light component realizes the separation of oil and gas through condensation, and the gas is used for chemical raw materials after separation and purification, and carbon tetrachloride (CCl 4 ) is the oil mixed with solvent and oil and purified by rotary e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com