Auxiliary cable mounting equipment for power transmission network

A technology for installing equipment and transmission networks, which is applied in the direction of overhead lines/cable equipment, mechanical equipment, springs/shock absorbers, etc. It can solve problems such as lack of cables, intertwining of cables, messy placement of cables, etc., and achieve practicability Strong, scientific and reasonable design, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

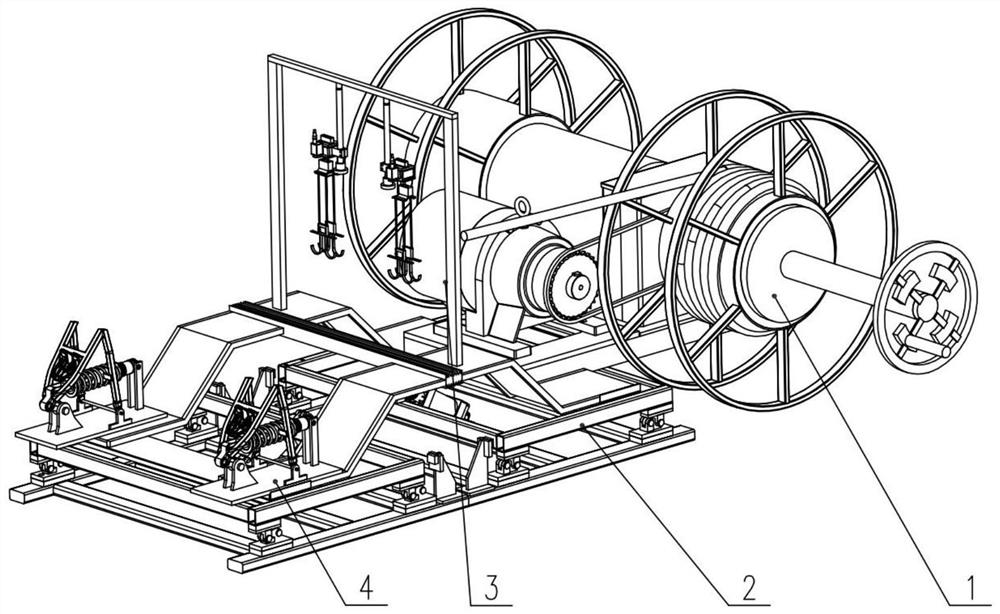

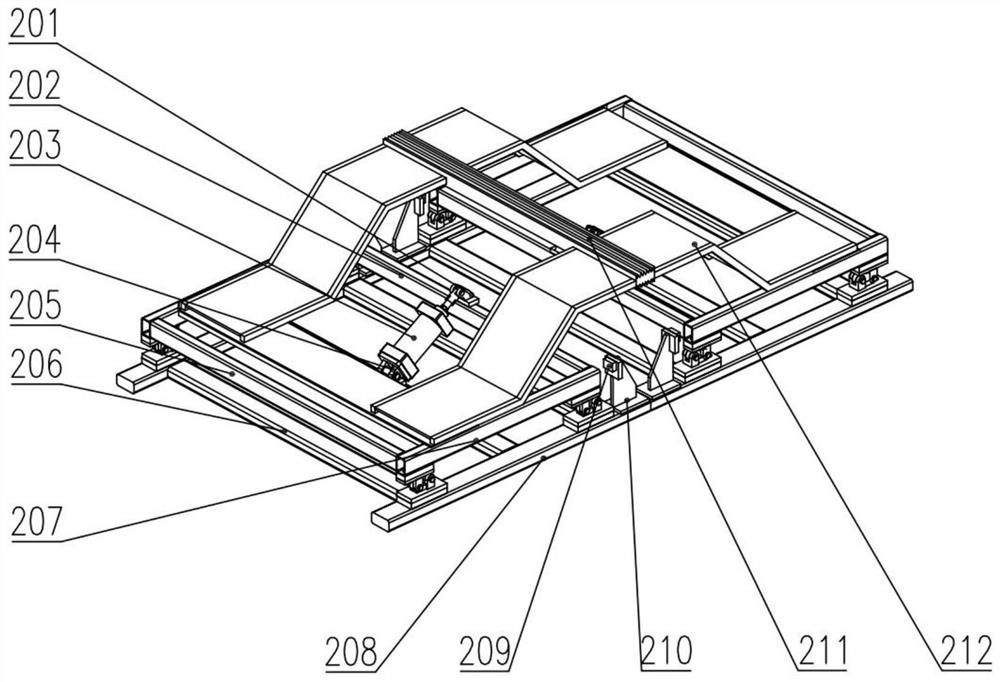

[0022] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The auxiliary cable installation equipment for the power transmission network includes a hoisting device 1 , an adjusting chassis 2 , a branching device 3 , and a caliper device 4 .

[0023] The specific structure of the cable auxiliary installation equipment of a transmission network is as follows: figure 1 As shown, the hoisting device 1 is fixedly installed on the adjustment base frame 2, the adjustment base frame 2 is fixedly installed on the ground, the line distribution device 3 is fixedly installed on the adjustment base frame 2, and the caliper device 4 is fixedly connected to the adjustment base frame 2 superior. The cable pipeline barrel to be installed is fixedly installed on the equipment, wherein the adjusting chassis 2 is used as the main support structure to carry the hoisting device 1 , the branching device 3 and the caliper device 4 .

[0024] The concrete structure of hoisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com