Optical delay structure

A technology of optical delay and optical components, applied in the field of optics, can solve the problems of complex and time-consuming disassembly and debugging, low speed of the stage, and long scanning time, and achieve the effects of convenient laying and debugging, high precision, and short scanning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Various embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. In each of the drawings, the same elements are expressed by the same or similar reference numerals. For the sake of clarity, the various parts in the drawings are not drawn.

[0025] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

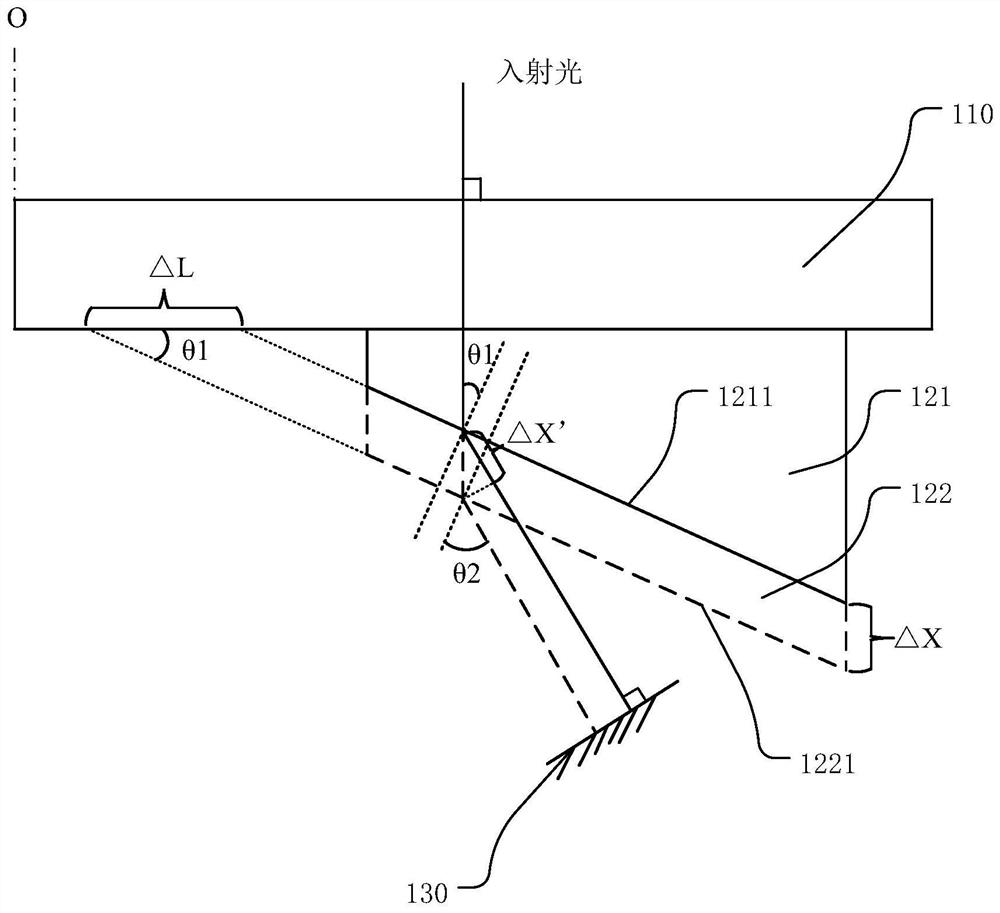

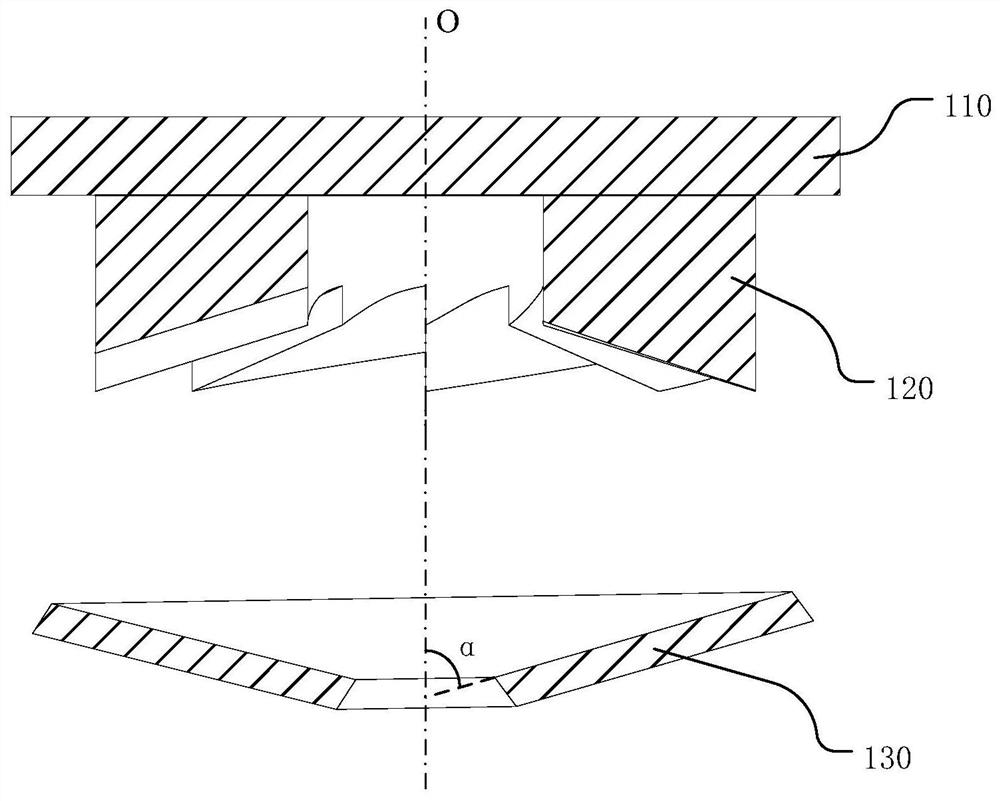

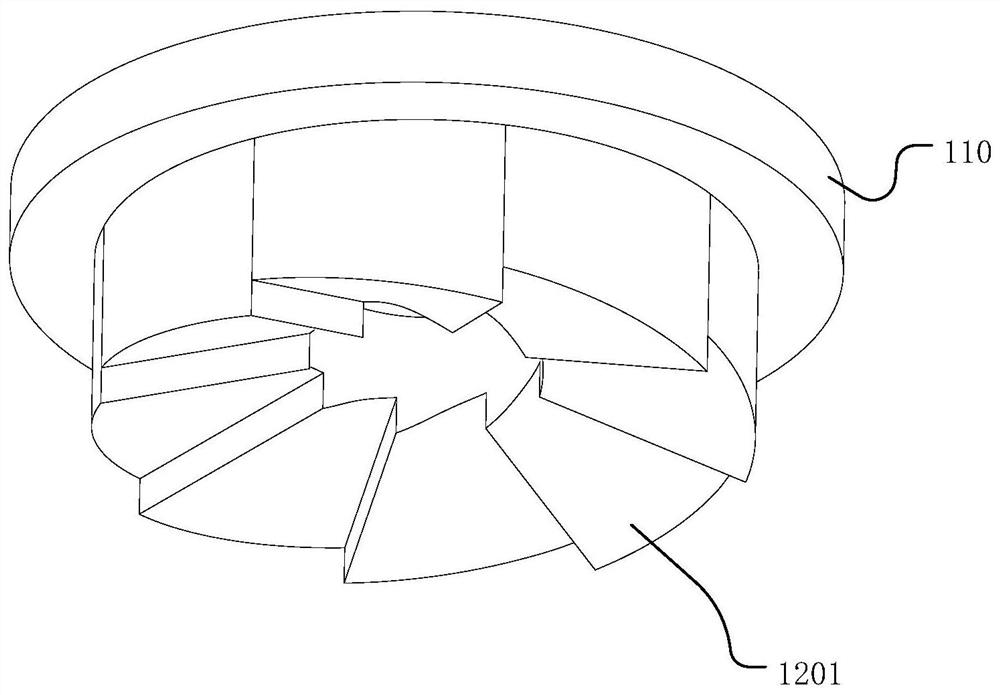

[0026] figure 1 The principle of the optical delay structure of the embodiment of the present invention is shown; figure 1 As shown, the optical delay structure includes: the turntable 110, the optical member 120, the mirror 130, wherein the turntable 110 is a uniform transparent medium disk having a refractive index of n, and the turntable 110 can rotate along the axis O, incident light. The incident point position is not changed, and the lower surface of the turntable 110 is provided with an optical member 120, in order to illustrate the principle of the optical delay structure, so figure 1 The first cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com