Detection machine for curved glass

A curved glass and detection machine technology, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inaccurate detection of curved glass appearance, reduce poor lighting conditions, improve lighting environment, and comprehensive lighting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

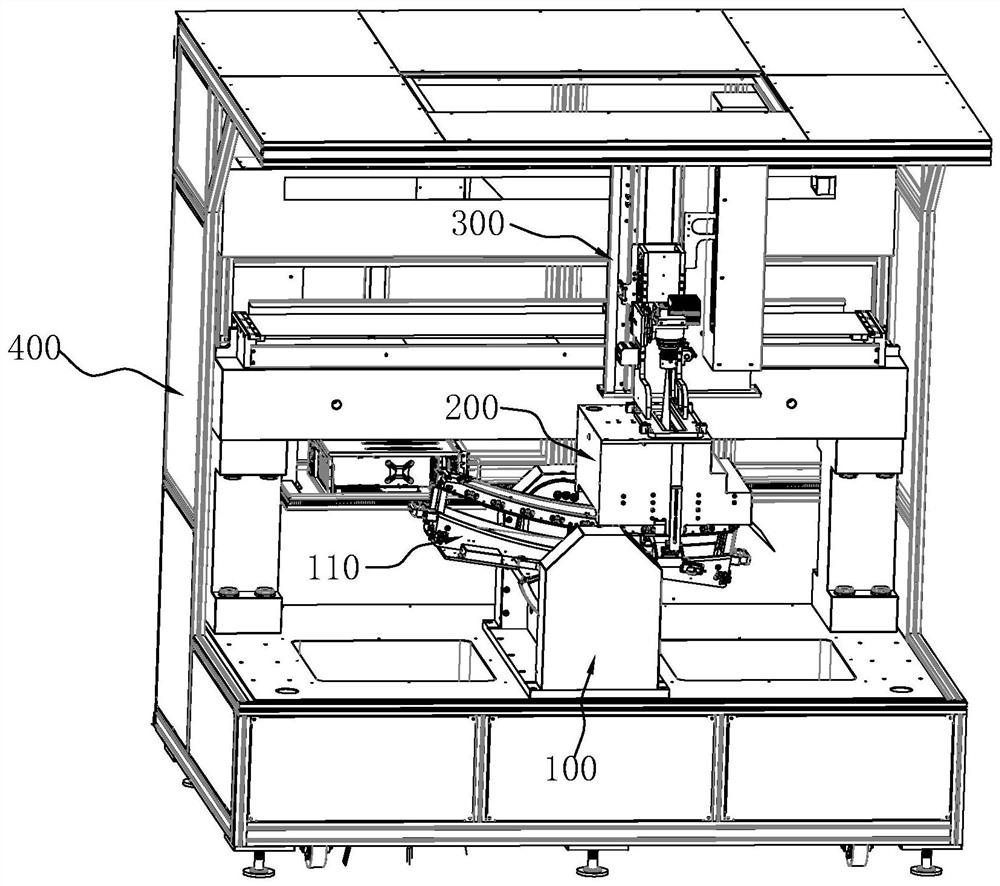

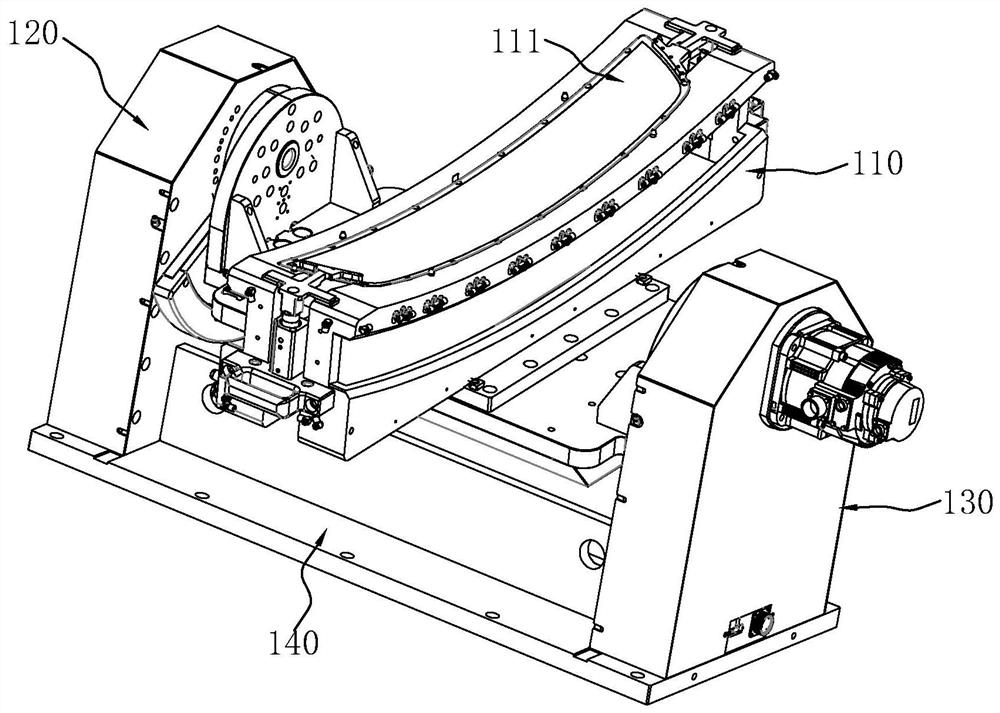

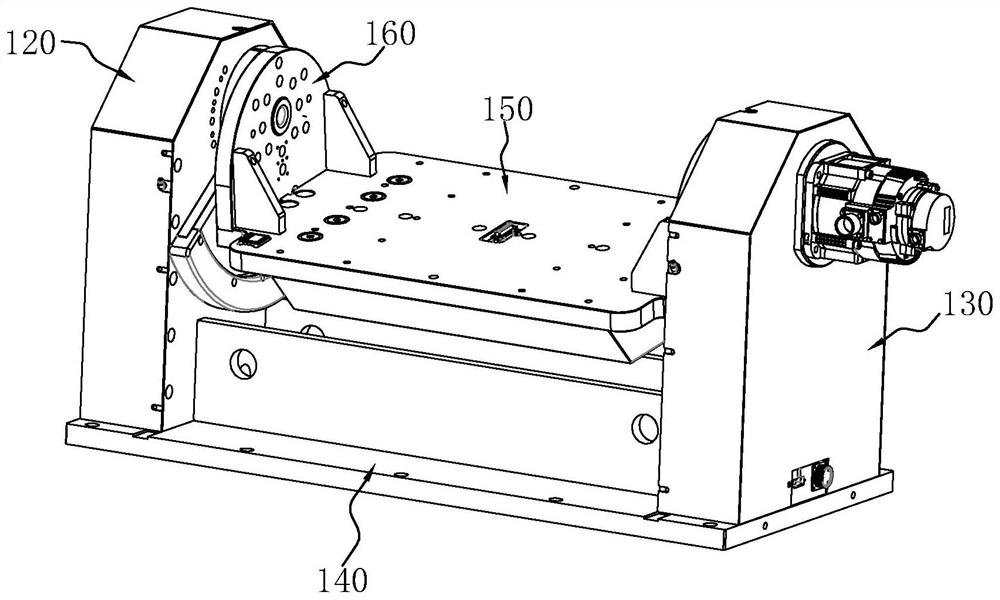

[0054] Please refer to Figure 1-Figure 10 , the invention discloses a detection machine for curved glass, including a camera for detecting curved glass, and also includes:

[0055] The swing device 100 is used to drive the curved glass 111 to swing along the arc;

[0056] The moving device 300 is used to drive the camera 360 to move. The moving device 300 includes: a first sliding assembly that can slide in a first direction relative to the curved glass 111; a second sliding assembly that is slidably connected to the first sliding assembly , and the second sliding assembly can slide in a second direction relative to the first sliding assembly, the second sliding assembly is used to connect with the camera 360; the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com