Solid rocket engine inner cavity volume measurement method and device based on laser point cloud

A solid rocket, laser point cloud technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low efficiency, cumbersome operation, and inability to adapt, and achieve fast transmission speed, high flexibility, and fast operation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

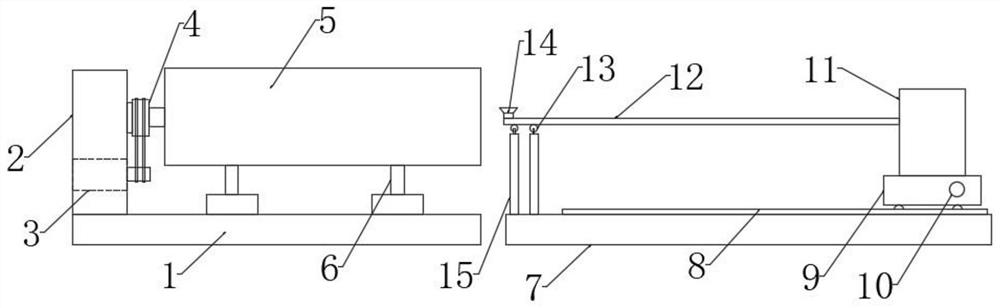

[0041] A method for measuring the volume of an inner cavity of a solid rocket motor based on a laser point cloud, comprising the following steps:

[0042] Step 1, use the line laser displacement sensor to collect the displacement value of the inner surface of the solid rocket motor cavity, and use the D-H matrix to convert the data collected by the line laser displacement sensor into the three-dimensional point cloud data of the solid rocket motor cavity. The specific steps are:

[0043] Step 1.1, combining the movement of the line laser displacement sensor along the axis of the solid rocket motor and the rotation of the solid rocket motor itself, collecting the displacement values of the inner cavity surface of the solid rocket motor at equal intervals, and performing D-H modeling on the data collected by the line laser displacement sensor , the D-H matrix can be obtained:

[0044]

[0045] Step 1.2, multiply the data collected by the line laser displacement sensor with ...

Embodiment 2

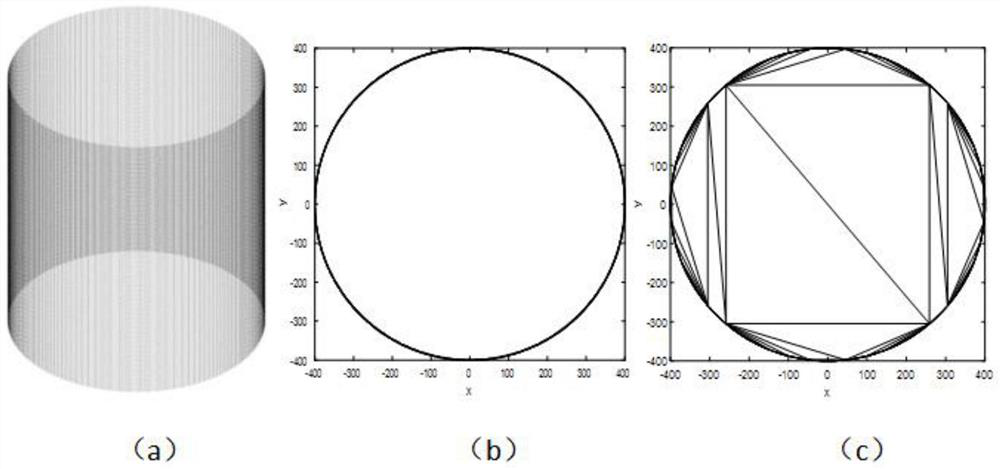

[0065] Simulation Cylindrical Measurement

[0066] The combustion chamber of the solid rocket motor belongs to a large length-to-diameter ratio tubular object, and its precise geometric size is unknown. In order to verify the accuracy of the volume measurement method proposed by the present invention, a cylinder with a height of 2000mm and a radius of 400mm was simulated using MATLAB (such as figure 2 ), and manually calculate its real volume in advance, and take the real volume as the theoretical value. At the same time, the volume of the cylinder is measured by using the algorithm of the present invention and the pixel method of Document 1, and the validity of the algorithm is verified by calculating the relative error (Formula 5). Experimental results such as figure 2 , Table 1 shows.

[0067] Relative Error Calculation Formula

[0068]

[0069] Among them, V 1 is the measured volume and V is the theoretical value.

[0070] Table 1 Comparison of the volume measure...

Embodiment 3

[0074] Measurement of cavity volume in solid rocket motor

[0075] Although the traditional "weighing method" is cumbersome and inefficient, it has high measurement accuracy. Therefore, the volume measured by the traditional "weighing method" is used as the theoretical value, and the volume of the combustion chamber cavity in the method of the present invention and the pixel method is calculated. Measure the relative error to further judge and verify the efficiency and applicability of the two algorithms. Experimental results such as image 3 , Table 2, Table 3 shown.

[0076] Table 2 Area of each point cloud slice

[0077] Number of point cloud slices Area (mm 2 )

The first point cloud slice 488367.36 The second point cloud slice 489071.38 The third point cloud slice 489540.22 The fourth point cloud slice 490009.99 The fifth point cloud slice 490009.99 The sixth point cloud slice 490952.27 The seventh point cloud sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com