Integrated rotary upright catwalk

A catwalk and main body technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of reduced service life and reliability, reduced safety, easy damage during disassembly and assembly, etc., to improve transportation efficiency and convenience. Fault detection, the effect of a high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

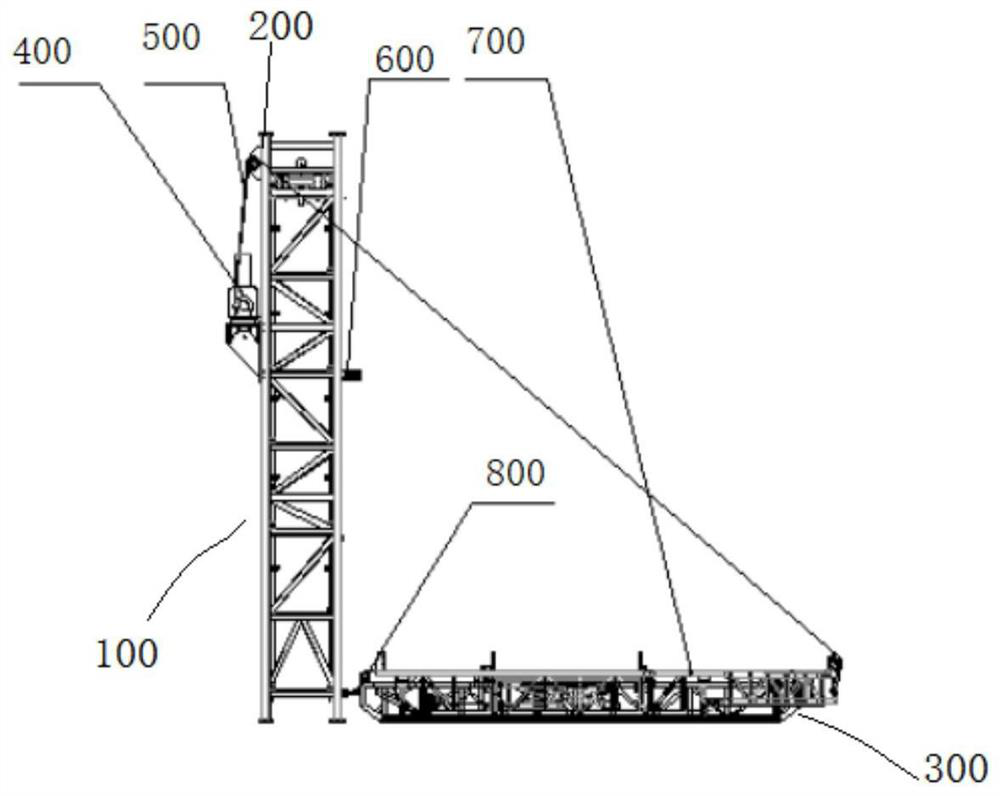

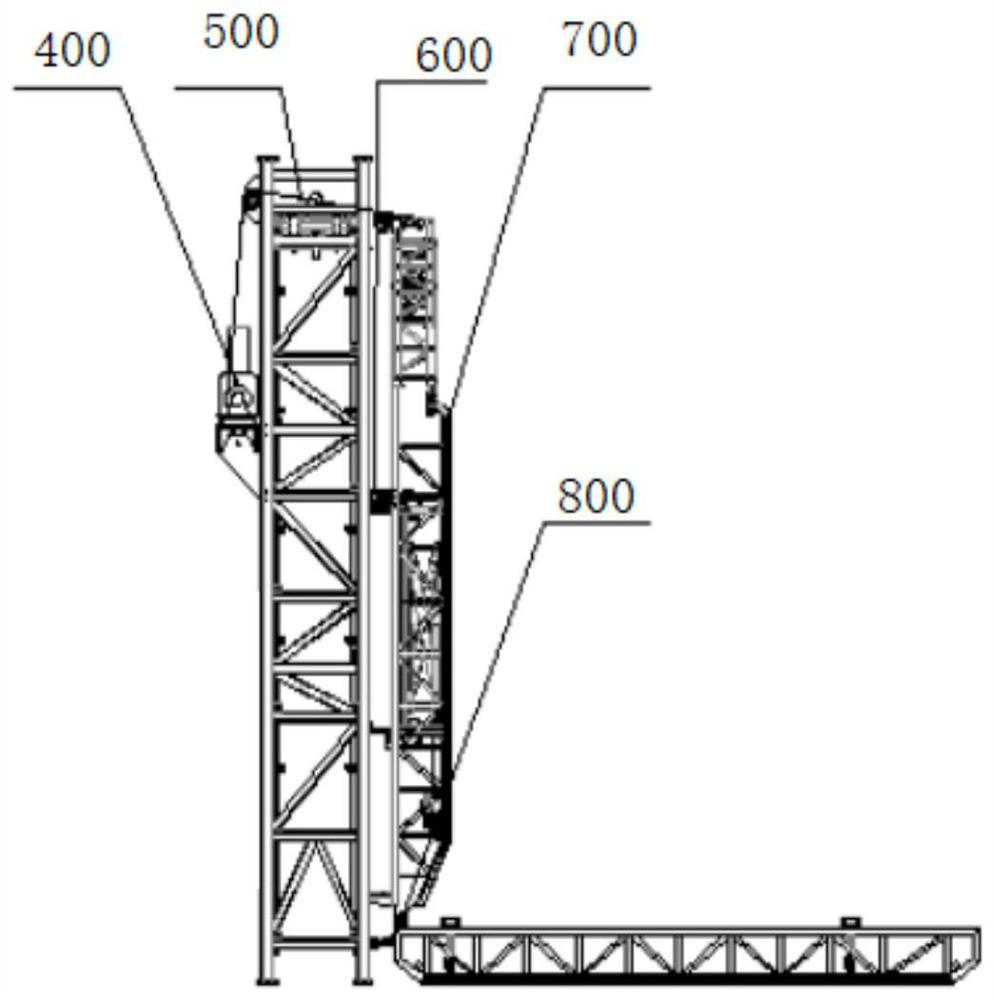

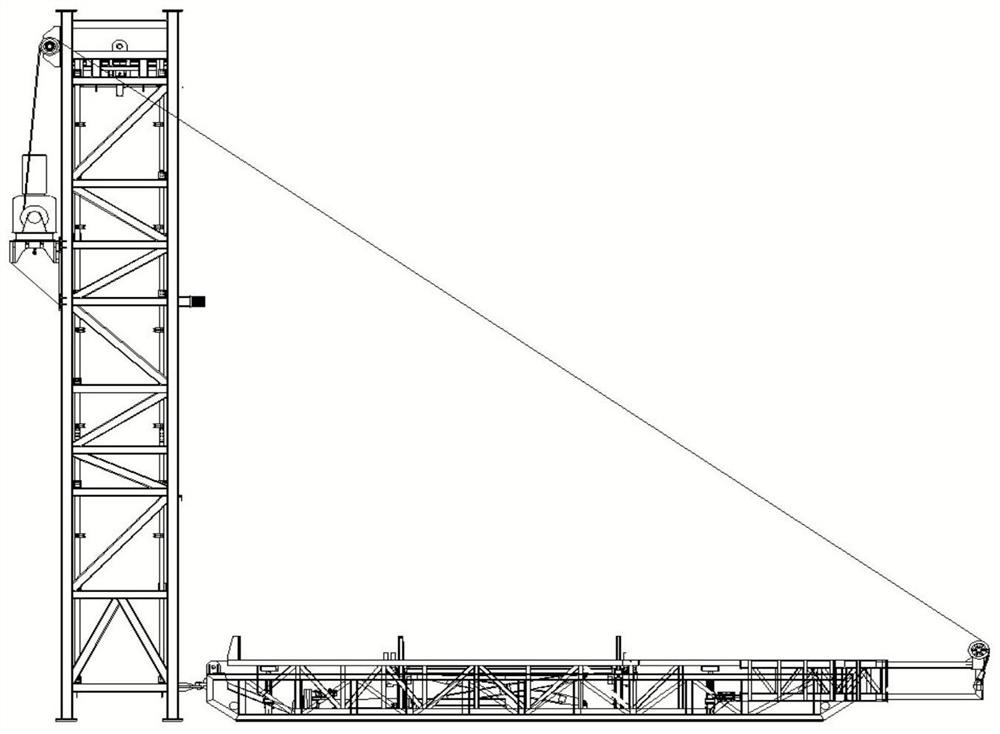

[0032] An integrated rotating upright catwalk, comprising: a fixed main frame body 100, a rotating upright catwalk main body 700, one end of the rotating upright catwalk main body is pivotally connected to a hinge mechanism 800, and can rotate around the hinge mechanism; Mechanism 400, the power cables 500 connected to the power mechanism are respectively connected to the other end of the rotating upright catwalk main body 700 via rollers 200, and can drive the rotating upright catwalk main body to move between the horizontal direction and the vertical direction. switch.

[0033] Further, a rotating upright catwalk buffer device 600 is provided on the side of the main frame that is in contact with the main body of the rotating upright catwalk, and the rotating upright catwalk buffering device is vertically assembled on the main frame body.

[0034] When the rotating catwalk rotates to 90 degrees, the rotating upright catwalk buffer device 600 works, which can effectively prote...

Embodiment 2

[0040] In order to better achieve the above purpose, the main frame body 100 is vertically fixed on the horizontal plane, and in the longitudinal direction, the height of the power mechanism 400 is higher than that of the rotating upright catwalk buffer device 600, and the rollers 200 are located on the main frame body top area.

[0041] The main body of the rotating upright catwalk includes a supporting drill truss mechanism, and a telescopic structure 300 is arranged at the end of the supporting drilling truss mechanism, and the length of the rotating upright catwalk main body is correspondingly adjusted according to the length of the drilling tool.

[0042] In addition, the central clamping lever mechanism is assembled in the main body of the rotating upright catwalk. Because drilling tool is arranged in the rotating upright catwalk, the drilling tool is driven, and the same state is reached with the rotating upright catwalk. The main body of the rotating inner frame is pr...

Embodiment 3

[0045] For details, see Figure 4-Figure 6As shown, the specific structure of the retractable structure 300; in the present invention, the vertical lifting device for drilling tools is provided with a centering and clamping rod mechanism for multiple drilling tools of various drilling tools. When multiple drilling tools enter the vertical lifting device During the frame, the bottom left and right clamping mechanism 6 in the inner frame of the vertical lifting device plays a role in ensuring that the drilling tool is centered at the bottom left and right when lifting.

[0046] The bottom in the inner frame of the vertical lifting device rotates the front and rear clamping mechanism 7 to ensure that the drilling tool is centered at the bottom front and back when lifting.

[0047] The top rotating front and rear clamping mechanism 9 in the inner frame of the vertical lifting device ensures that the drilling tools are centered in the front and back of the top during lifting, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com