Simple physical defoaming method

A kind of physical defoaming and simple technology, applied in the direction of degassing water/sewage treatment, etc., can solve the problems of foam polluted land, foam overflowing sewage wells, entering municipal sewage pipe network, etc., achieving simple defoaming structure, good economic benefits, Good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

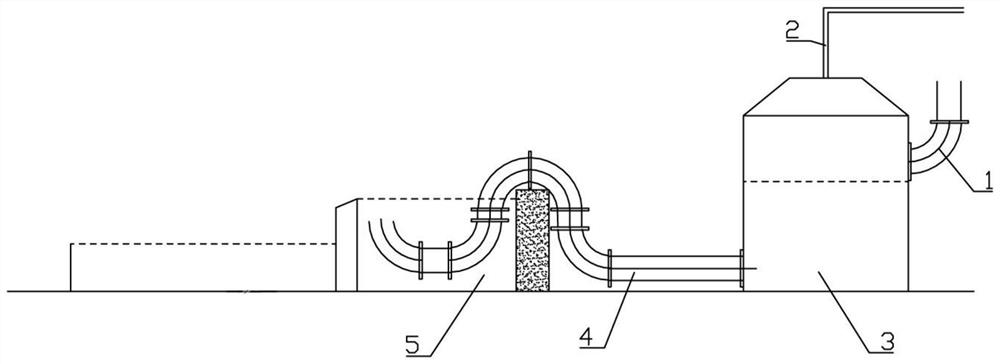

[0018] Such as figure 1 As shown, a kind of simple and easy physical defoaming method of the present invention, the waste water with foam that the waste water station treats up to standard is connected in the plastic barrel 3 through the liquid inlet pipe 1, and the liquid inlet pipe 1 is connected from the upper end side of the plastic barrel 3 Connected, the waste water mixture with foam is separated in the plastic bucket 3, the foam is at the upper end of the plastic bucket 3, the water is at the lower end of the plastic bucket 3, and the foam is discharged from the foam removal pipe 2 connected to the plastic bucket 3, and discharged to the regulating tank 3. The pool defoams naturally, and waste water without foam is removed from the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com