Automatic cutting, hanging and airing device for processing bean medicinal materials

A technology for automatic cutting and processing of medicinal materials, which is applied in metal processing, lighting and heating equipment, dryers for static materials, etc., can solve the problems of large force on medicinal materials, affecting product quality, deformation, etc. The effect of good quality and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

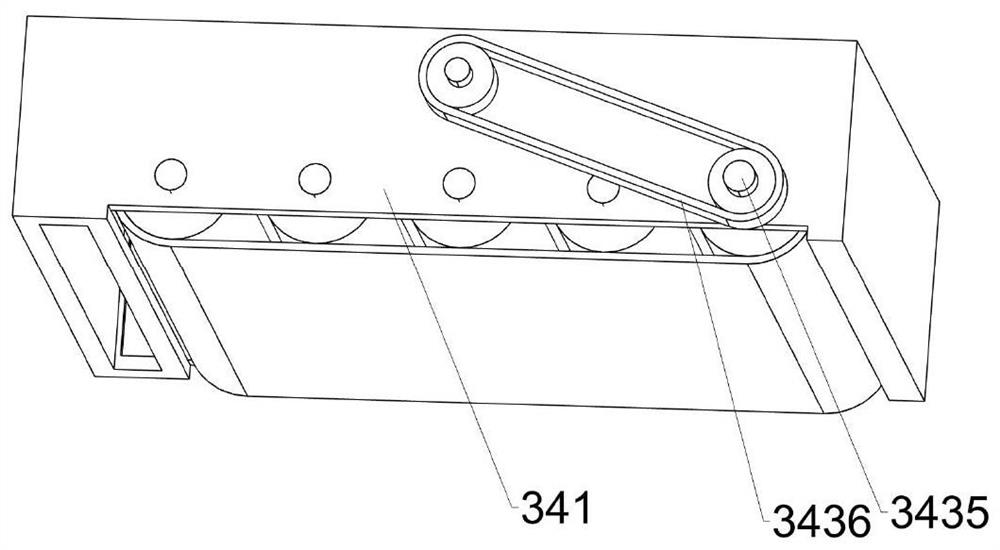

[0028] Such as Figure 1-15 As shown, an automatic cutting and hanging drying device for processing beans and medicinal materials, including a first support frame 1, a cylinder 2 arranged above the first support frame 1, and a cylinder 2 arranged above the first support frame 1 for supporting the cylinder 2. The first support plate 11, the automatic cutting structure 3 arranged at the output end of the cylinder 2 for automatically cutting off the medicine bar 6 of the bean medicine, and the side of the first support frame 1 for extruding the bean medicine downward The discharge barrel 5 of the drug bar 6, the discharge head 51 located at the bottom of the discharge barrel 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com