Multi-stage transmission axle gear box

A technology for axle gearboxes and large gears, applied to transmissions, transmission parts, gear transmissions, etc., can solve the problems of insufficient space utilization, small deceleration, and small driving force, and achieve large driving force and deceleration. The effect of large and large transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

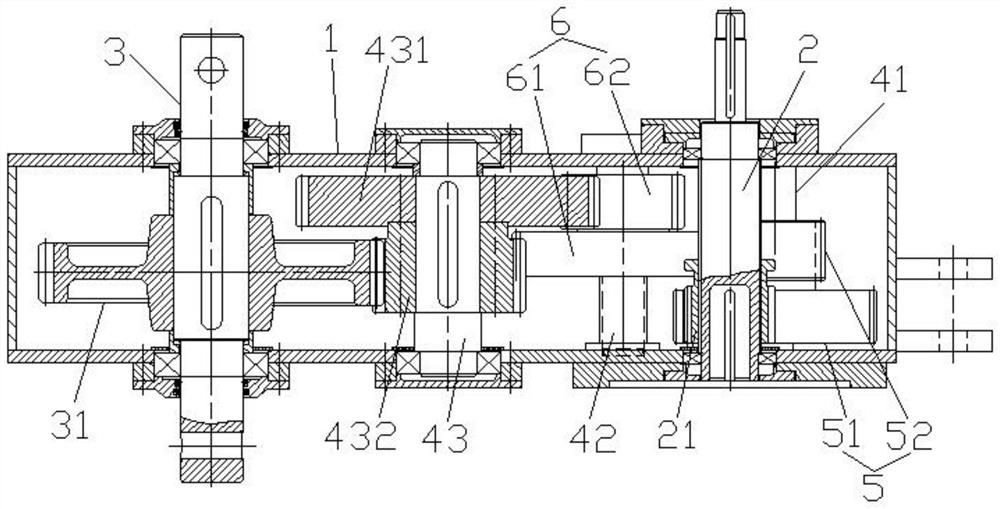

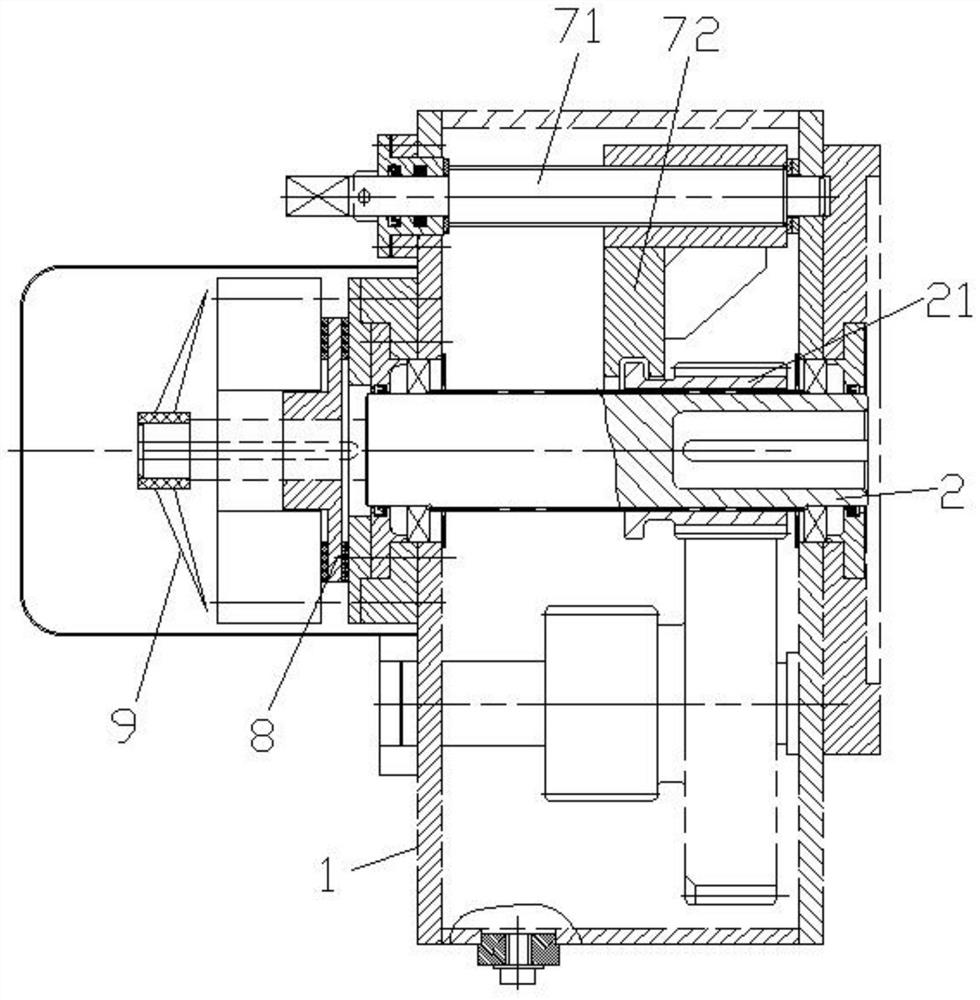

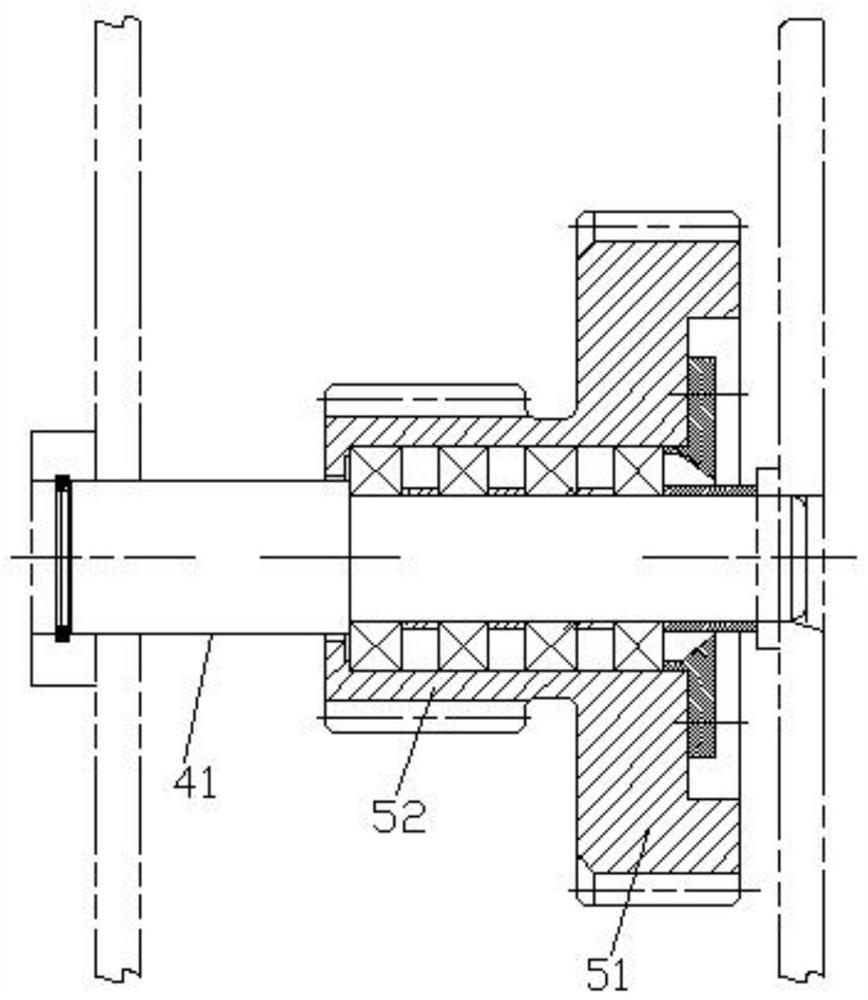

[0025] Example: such as figure 1 As shown, the multi-stage transmission axle gearbox of this embodiment includes a box body 1, an input shaft 2, an output shaft 3 and a multi-stage gear transmission assembly, and the above-mentioned input shaft 2 is mounted on both sides of one end of the above-mentioned box body 1 so as to be rotatable laterally On the inner wall, an input gear 21 is arranged on it, and the above-mentioned output shaft 3 is mounted on the inner wall on both sides of the other end of the above-mentioned box 1 so as to be rotatable in the transverse direction, and an output gear 31 is arranged on it, and the above-mentioned multi-stage gear transmission assembly is assembled on the above-mentioned The box body 1 is connected to the input gear 21 and the output gear 31 respectively.

[0026] The internal layout of the gear box in this embodiment is reasonable, multi-stage transmission, the transmission ratio can reach 31.89, the transmission ratio is large, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com