Concentrate for rapid reduction type hydraulic support in low temperature environment and preparation method thereof

A low temperature environment, hydraulic support technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of pipeline system blockage, thrombus, affecting coal mine safety, high efficiency and high production, etc., to achieve reliable liquid supply and improve pumping capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

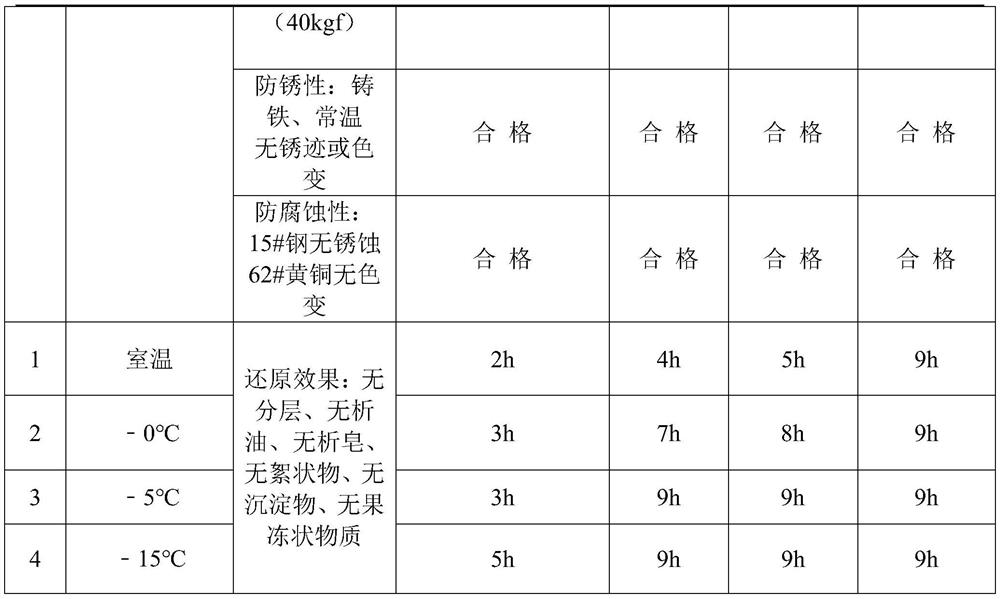

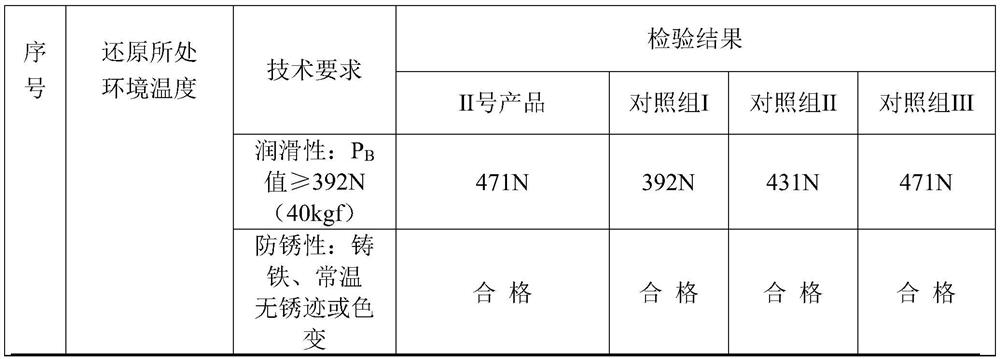

Examples

Embodiment 1

[0040] A concentrated solution for a rapid reduction type hydraulic support in a low temperature environment, the total mass parts of the preparation components are 100 parts, and the raw materials include: polymeric amino acids (polylysine and polyaspartic acid are mixed in a mass ratio of 1:1. ) 15 parts, 4 parts of non-ionic and anion-based composite coupling agents, 2 parts of alcohol amine buffer (triisopropanolamine and triethanolamine are mixed in a mass ratio of 1:1), 15 parts of organic and inorganic composite pour point depressants , 7.1 parts of non-ferrous metal and ferrous metal composite corrosion inhibitor, 3 parts of mold and bacteria inhibitor (natamycin and isothiazolinone are mixed in a mass ratio of 1:1), alcohol-modified polyether (allyl alcohol polyoxyalkane) base ether) 1 part, the balance is water.

[0041] In this embodiment, the mass ratio of nonionic and anionic composite coupling agent: water, nonionic coupling agent (dipropylene glycol monomethyl e...

Embodiment 2

[0057] A concentrated solution for rapid reduction type hydraulic support in a low temperature environment, the total mass parts of its preparation components are 100 parts, and the raw materials include: polymeric amino acids (polyaspartic acid and polyglutamic acid are mixed according to a mass ratio of 1:1. ) 10 parts, 7 parts of non-ionic and anion-based composite coupling agents, 3 parts of alcohol amine buffer (triethanolamine and diethanol monoisopropanolamine are mixed in a mass ratio of 1:1), organic and inorganic composite pour point depressant 20 parts, 10.1 parts of non-ferrous metal and ferrous metal composite corrosion inhibitor, mold and bacteria inhibitor (octanoyl hydroxamic acid and isothiazolinone are mixed in a mass ratio of 1:1) 2 parts, alcohol-modified polyether (specifically can be Fatty alcohol modified end-capped polyether, commercially available from Shanghai Jianyong Industrial Co., Ltd., item number CF-18) 2 parts, the balance being water.

[0058]...

Embodiment 3

[0073] A concentrated solution for a rapid reduction type hydraulic support in a low temperature environment, the total mass part is 100 parts, and the raw materials include: 6 parts of polymeric amino acids (polylysine and polyglutamic acid are mixed in a mass ratio of 1:1), non- 10 parts of ionic and anion-based composite coupling agents, 6 parts of alcohol amine buffer (mixed with triethanolamine and diethanol monoisopropanolamine in a mass ratio of 1:1), 30 parts of organic and inorganic composite pour point depressants, non-ferrous metals And 13.7 parts of ferrous metal composite corrosion inhibitor, mold and bacteria inhibitor (natamycin, octanoyl hydroxamic acid mixed in a mass ratio of 1:1) 1 part, alcohol-modified polyether (dodecyl alcohol polyoxyethylene ether) 3 parts, the balance is water.

[0074] In this example, nonionic and anionic composite coupling agent, water, nonionic coupling agent (dipropylene glycol monomethyl ether and triethylene glycol butyl ether a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com