Improved anti-collision device used in hoisting process of large-scale multi-corner-angle cantilever truss

A multi-angle, anti-collision technology, applied in transportation and packaging, load hanging components, processing of building materials, etc., can solve the problems of stone curtain wall damage, shaking, etc., to achieve strong practicability, novel structure, and ideal anti-collision effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

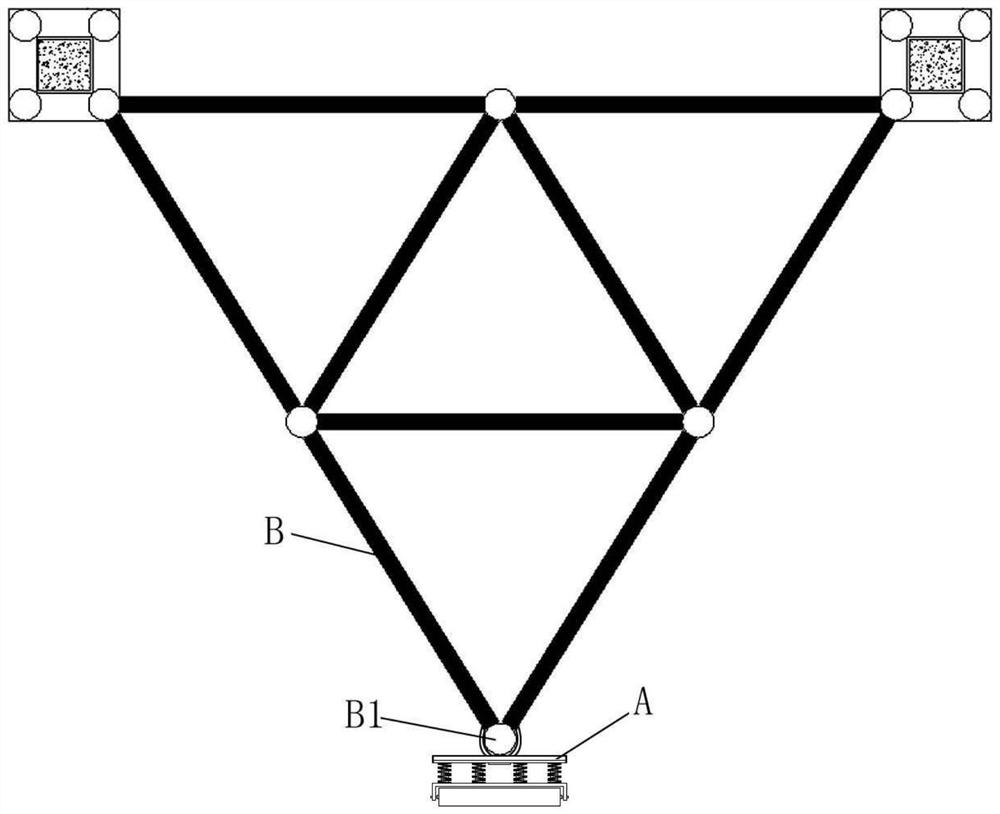

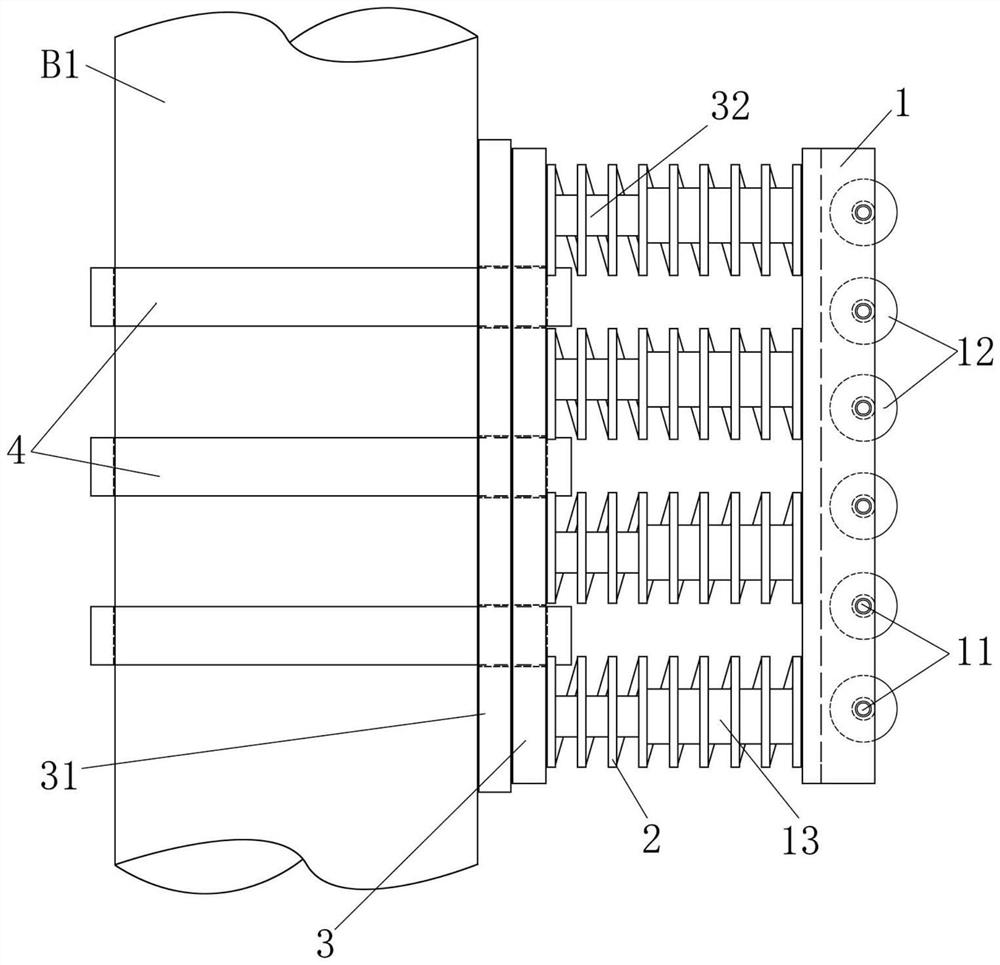

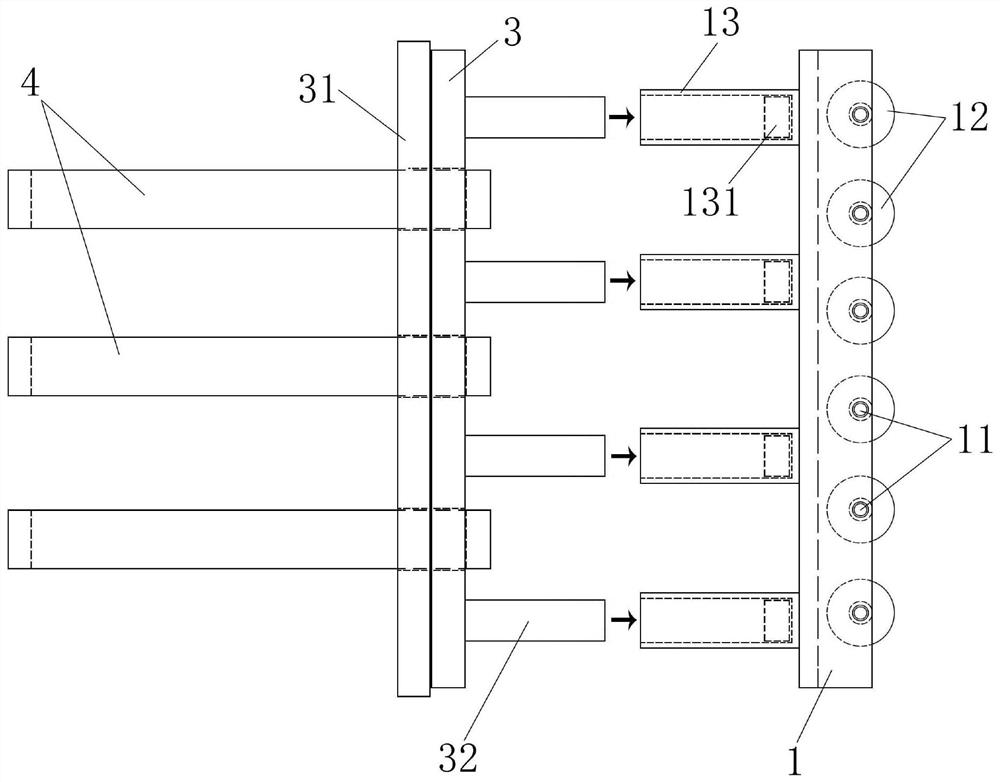

[0020] Such as figure 1 , figure 2 , image 3 As shown, the improved anti-collision device used in the hoisting process of large multi-angular cantilever truss is composed of front groove plate 1, rear wall plate 3, rubber gasket, telescopic spring 2, roller 11, rubber sleeve 12 1. Composition of 4 binding straps, characterized in that,

[0021] The U-shaped groove of the front groove plate 1 faces forward and is glued with a layer of rubber gasket 1. In the U-shaped groove of the front groove plate 1, 5 to 15 rollers 11 are movable in series, and the periphery of each roller 11 are wrapped with a rubber sleeve 12;

[0022] Roller 11 and rubber sleeve 12 are combined to form a roller mechanism;

[0023] There are 16 guide cylinders 13 fastened by welding on the back of the front groove plate 1, and a rubber block 131 is built in each guide cylinder 13, and the 16 guide cylinders 13 are arranged in four rows and four columns to form a cylinder square array;

[0024] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com