Effective dust removal device for base of garage kit

A kind of dust removal equipment and hand-made technology, which is applied in the direction of cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., which can solve the problems of time-consuming, labor-intensive, dusty and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

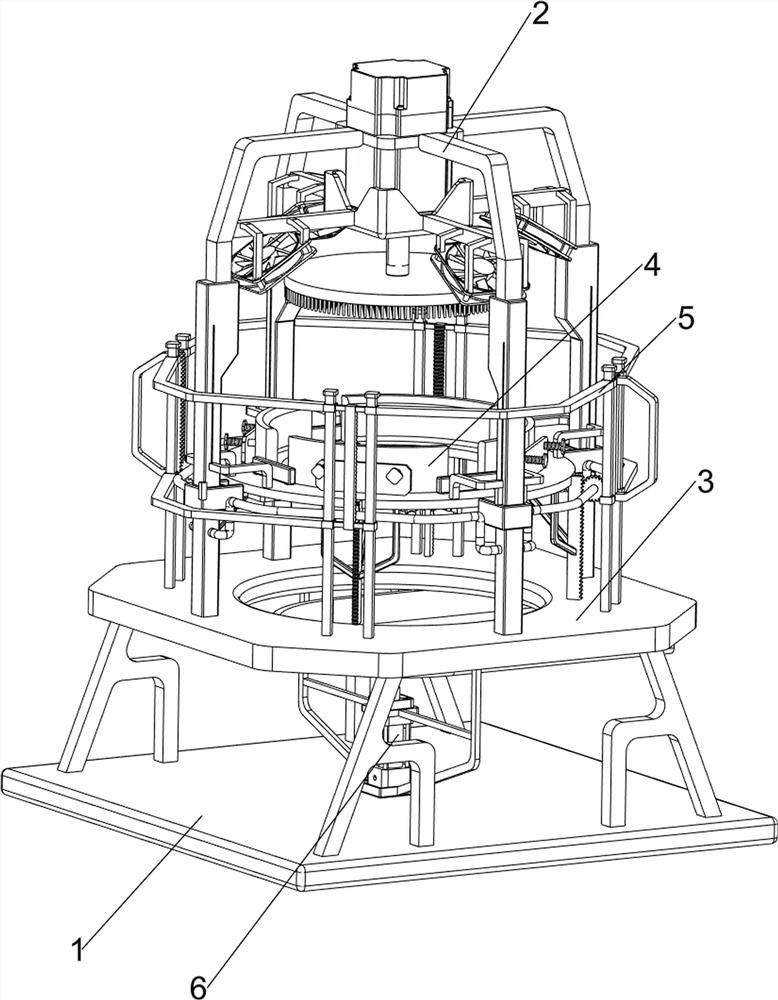

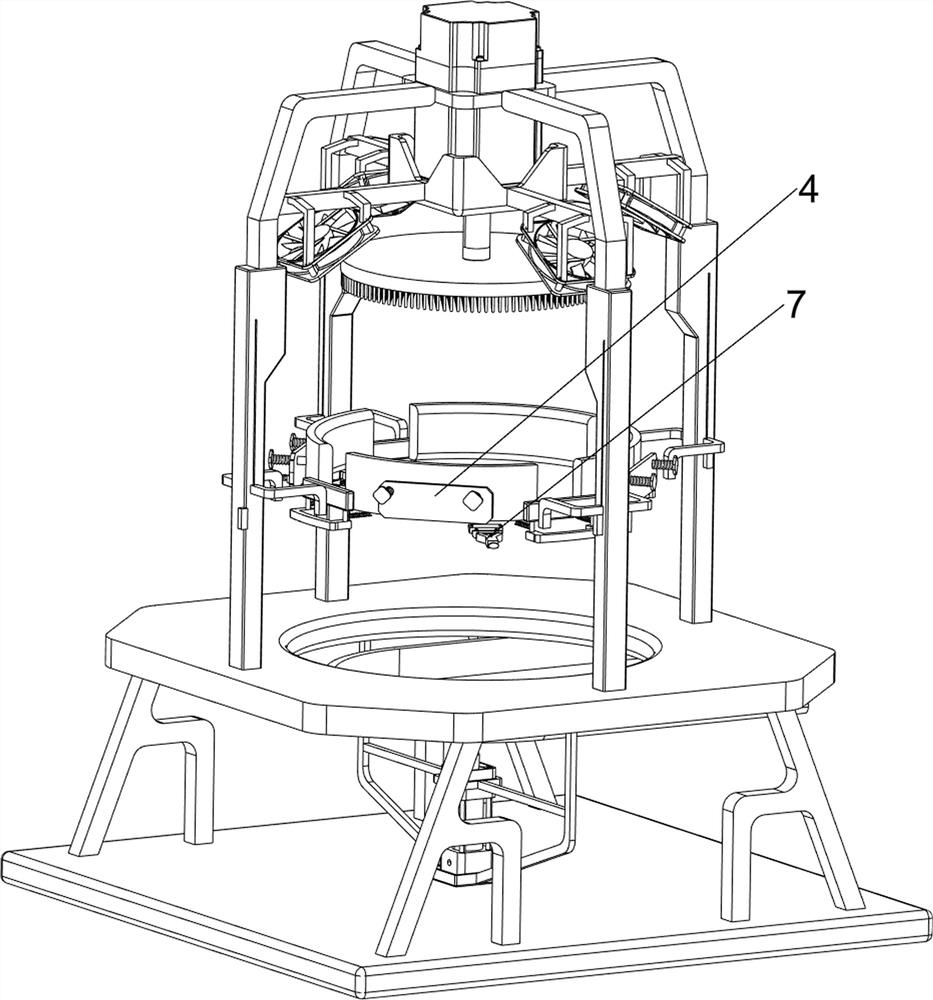

[0029] An effective dust removal device for a hand-made base, such as figure 1 , Figure 3-Figure 5 As shown, it includes a bottom plate 1 , a cleaning component 2 and a placement component 3 , the top of the bottom plate 1 is provided with a placement component 3 , and the top of the placement component 3 is provided with a cleaning component 2 .

[0030] People put the figure upside down on the placement component 3, start the cleaning component 2, and lift the placement component 3 upwards, so that the base of the figure contacts the cleaning component 2 to clean it, so as to achieve an efficient cleaning effect.

[0031] The cleaning assembly 2 includes a servo motor 21, a first support rod 22, a cleaning brush 23, a first connecting rod 24, and a fan 25. The top of the placement assembly 3 is provided with four first support rods 22 at intervals. A servo motor 21 is arranged between them, and a cleaning brush 23 is connected to the output shaft of the servo motor 21. A f...

Embodiment 2

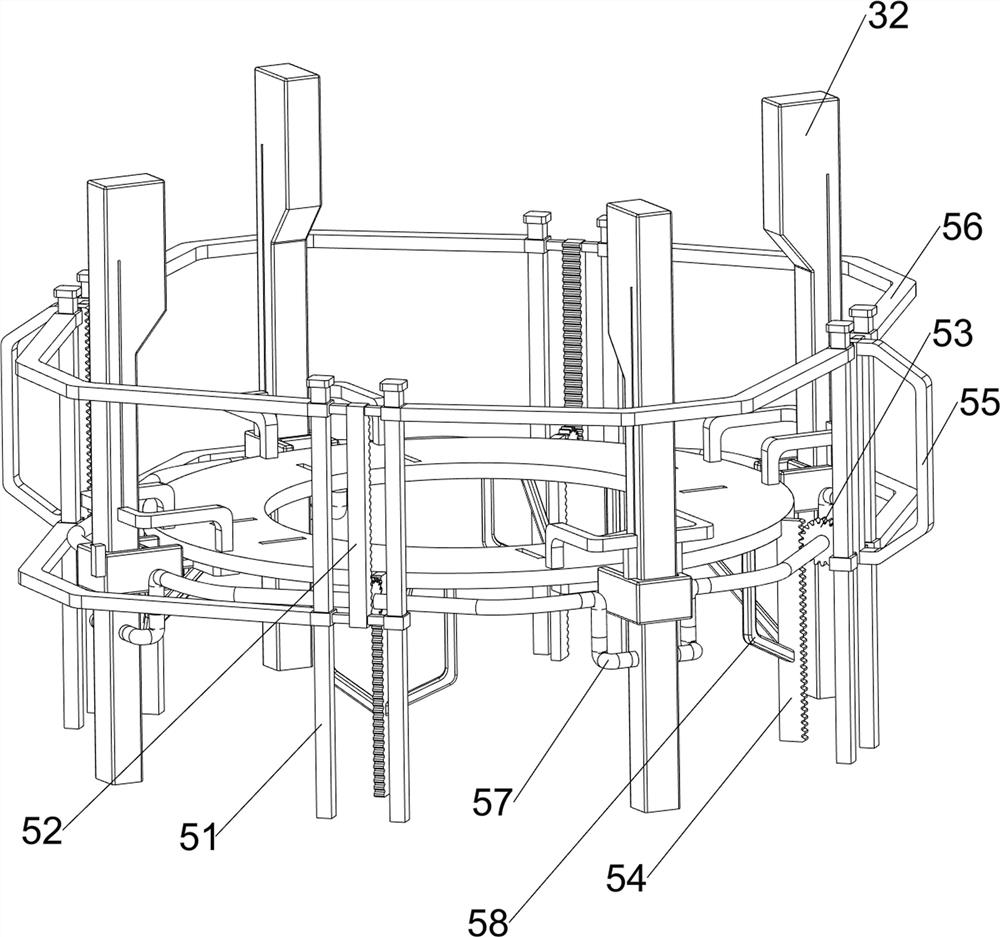

[0035] On the basis of Example 1, such as figure 2 , Figure 6-Figure 10As shown, a clamping assembly 4 is also included, and the clamping assembly 4 includes a clamping block 41, a first fixing block 42, a third connecting rod 43, a first spring 44, a first pushing block 45, and a fourth connecting rod 46 , the second fixed block 47 and the second spring 48, the top of the first placement table 33 is provided with four clamping blocks 41 in a symmetrical sliding manner at intervals, and the top of the first placement table 33 is provided with four first fixed blocks 42 at intervals and symmetrical intervals. A fixed block 42 is located outside the clamping block 41, and a third connecting rod 43 is symmetrically connected between the first fixing block 42 and the clamping block 41, and the third connecting rod 43 is slidably matched with the first fixing block 42, and the first A first spring 44 is connected between the fixed block 42 and the third connecting rod 43, and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com