Lithium battery module assembly production process

A production process and lithium battery technology, which is applied in the field of lithium battery module assembly production technology, can solve the problems of affecting economic benefits, poor size specifications of lithium battery modules, and position shifting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following is attached Figure 1-7 , to further describe this application in detail.

[0053] The embodiment of the present application discloses a lithium battery module assembly production process.

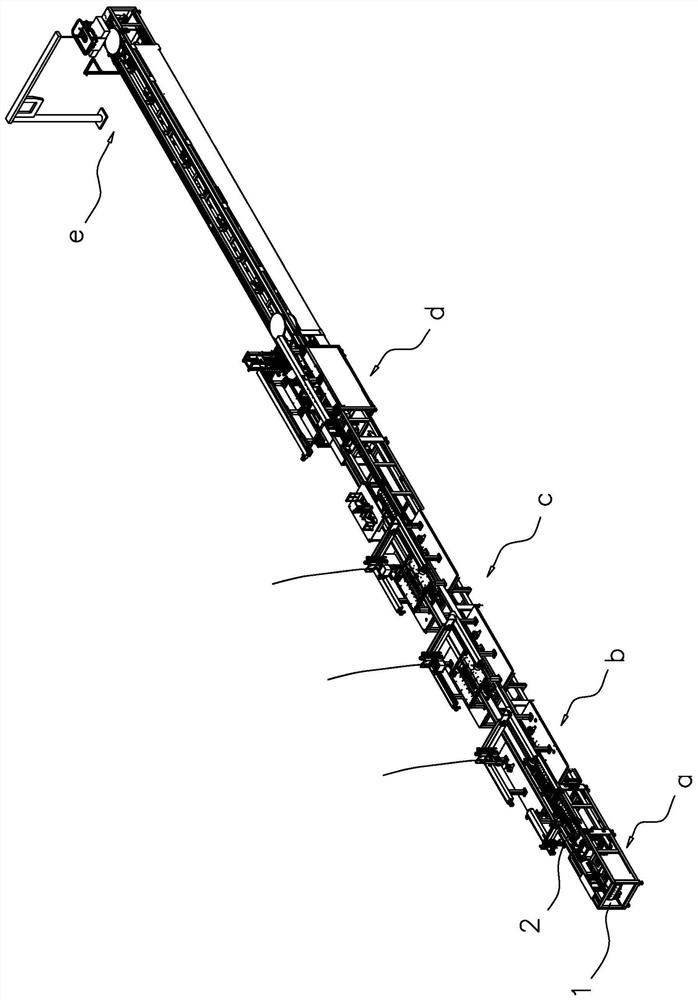

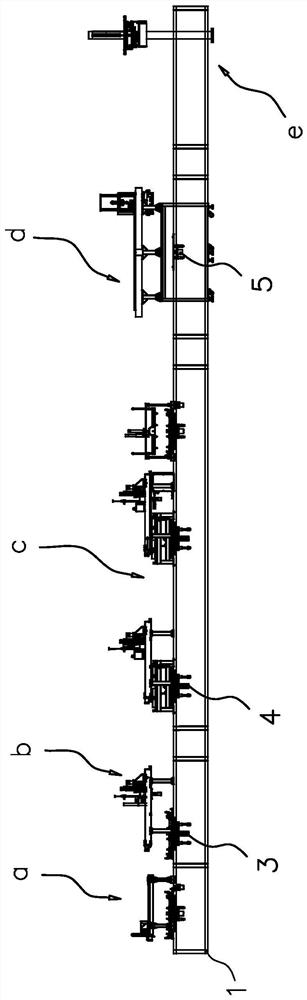

[0054] refer to figure 1 and figure 2 , the lithium battery module assembly production process requires the use of a lithium battery module assembly production line, which includes a tray 1 for placing groups of lithium batteries and a transport device 2 for transporting the tray 1 .

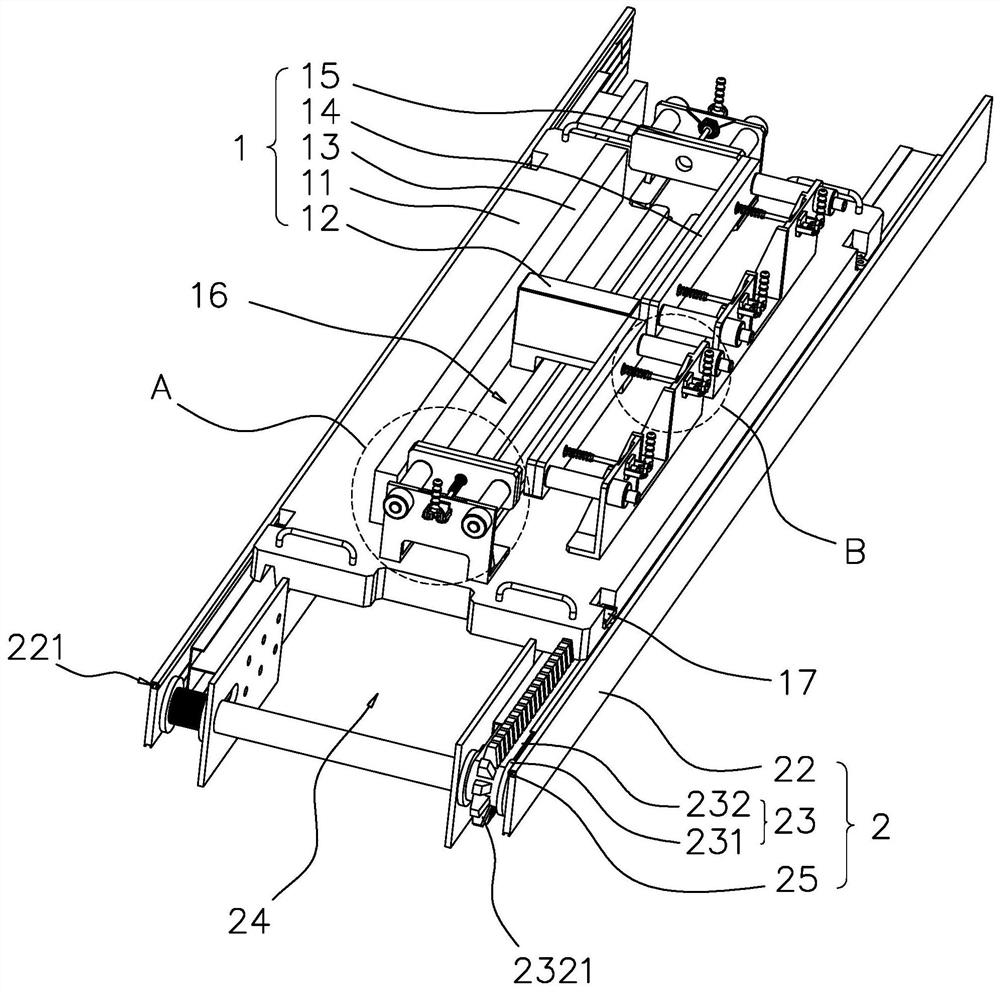

[0055] refer to image 3 , the tray 1 can make the lithium batteries that need to be welded into a module move stably, and make it possible to reduce the displacement between the lithium batteries as much as possible during the moving process, thereby reducing the occurrence of dimensional errors after welding. Specifically, the tray 1 includes a tray body 11 arranged substantially in a rectangular shape to have a length direction and a width direction in a horizontal direction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com