Relay socket

A relay socket and lifting bracket technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information and other directions, can solve the problems of lack of socket terminal protection, wire falling off, damaged terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

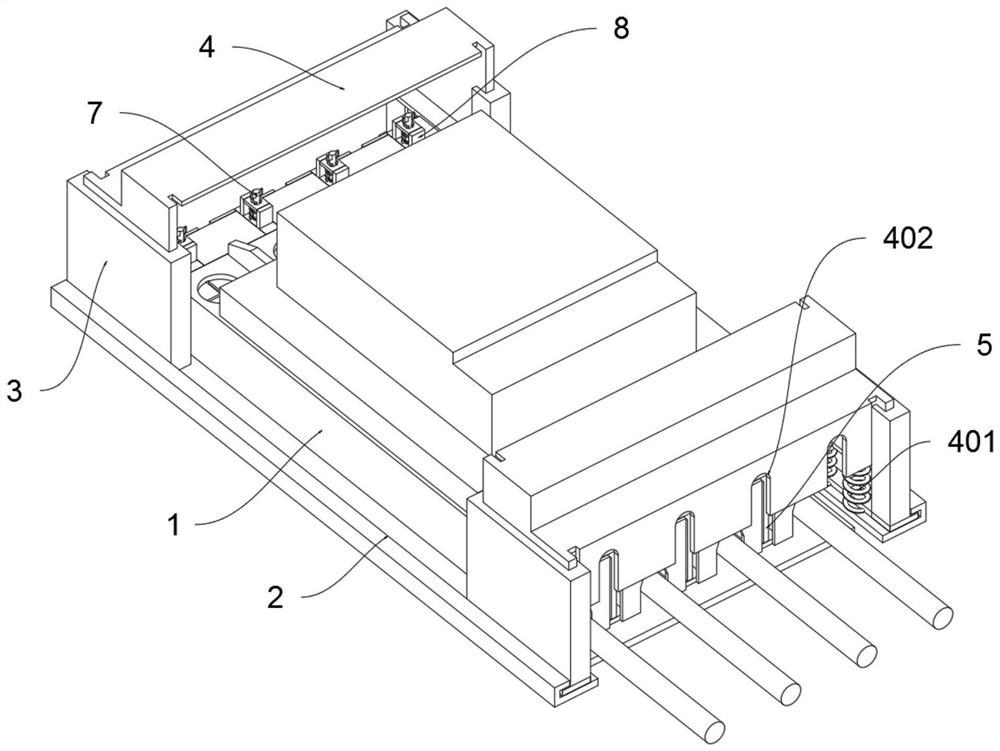

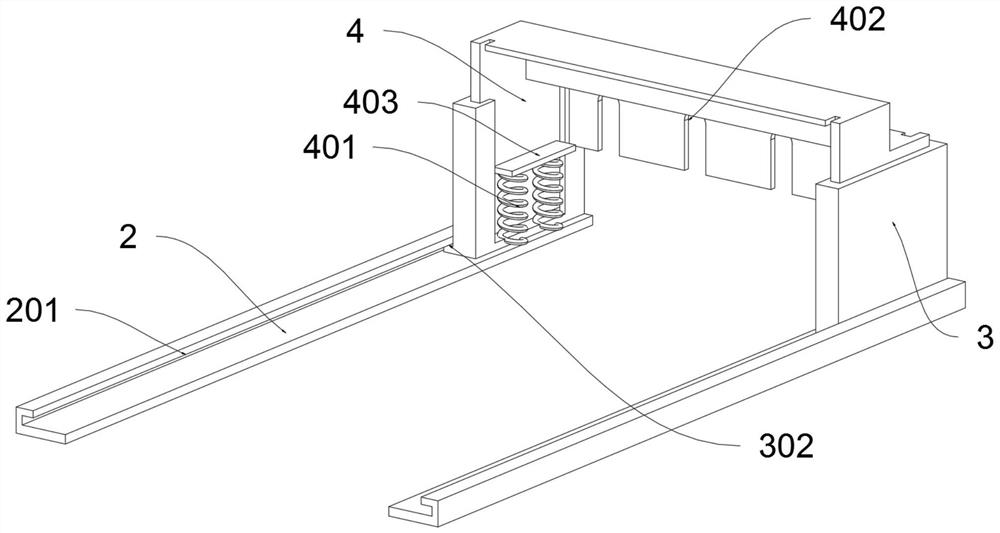

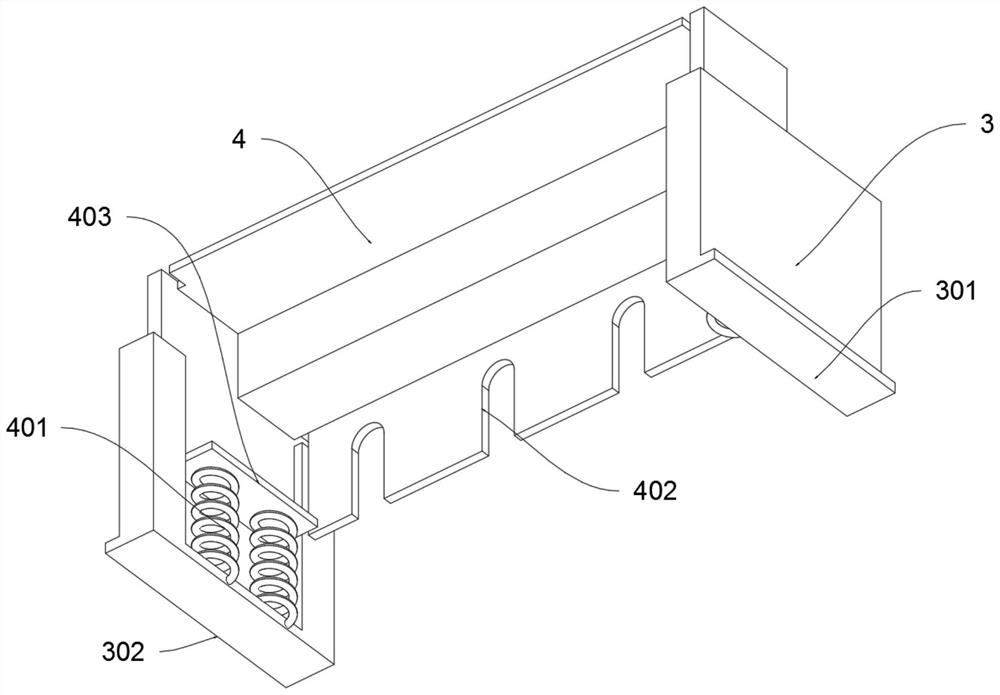

[0029] as attached figure 1 to attach Figure 7 Shown:

[0030] The invention provides a relay socket, comprising a base 1, a lifting bracket 3, a lifting guard 4, a joint partition 5, a guide hole 6, a spring tightening button 7, and a tightening column 8; the two sides of the base 1 are respectively fixedly connected with a There are two side moving brackets 2; there are two lifting brackets 3, which are slidably connected to the side moving bracket 2, and the two lifting brackets 3 are respectively located on the front side and the rear side of the side moving bracket 2; the lifting guard 4 is slidingly connected to the lifting bracket 3, and the lower end of the return spring 401 of the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com