Pipeline environment operation oriented reconfigurable folding and unfolding mechanism

A folding mechanism and environment technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of large curvature changes, complex and changeable inner diameters of pipe environments, complex and changeable pipe inner diameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

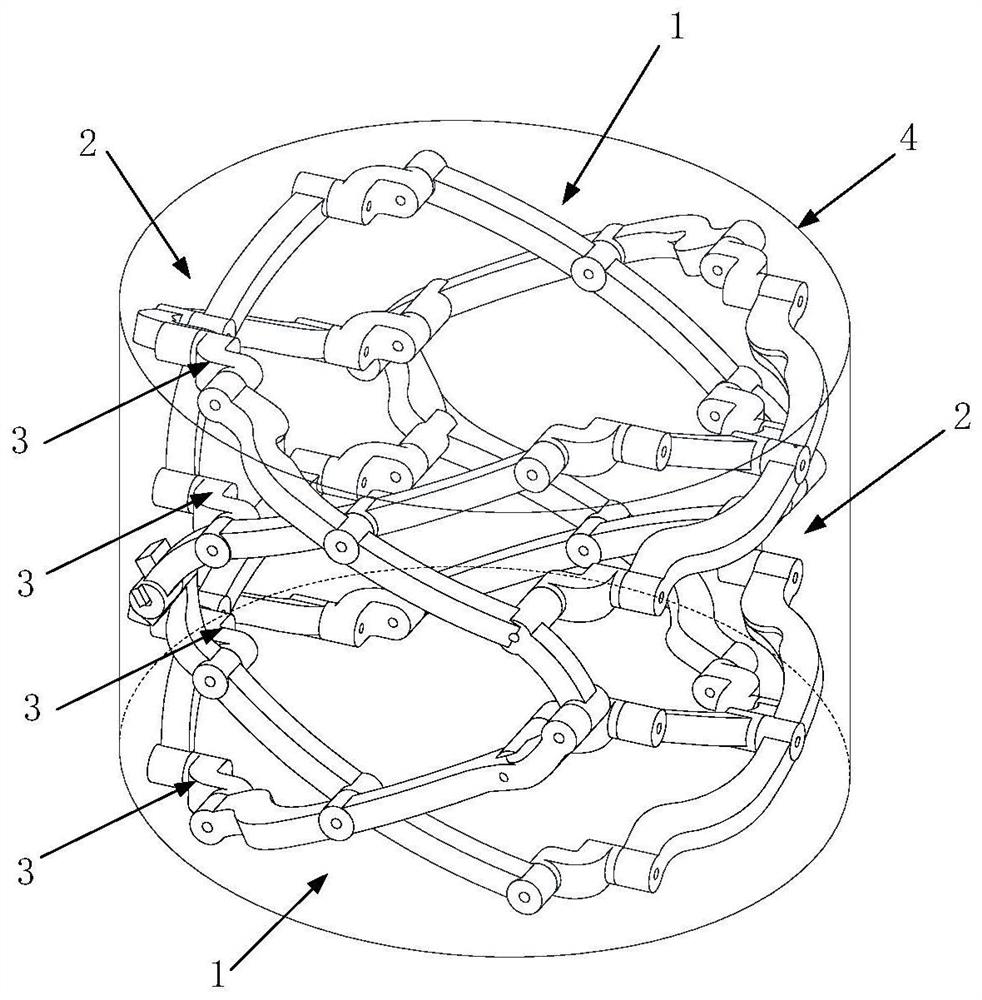

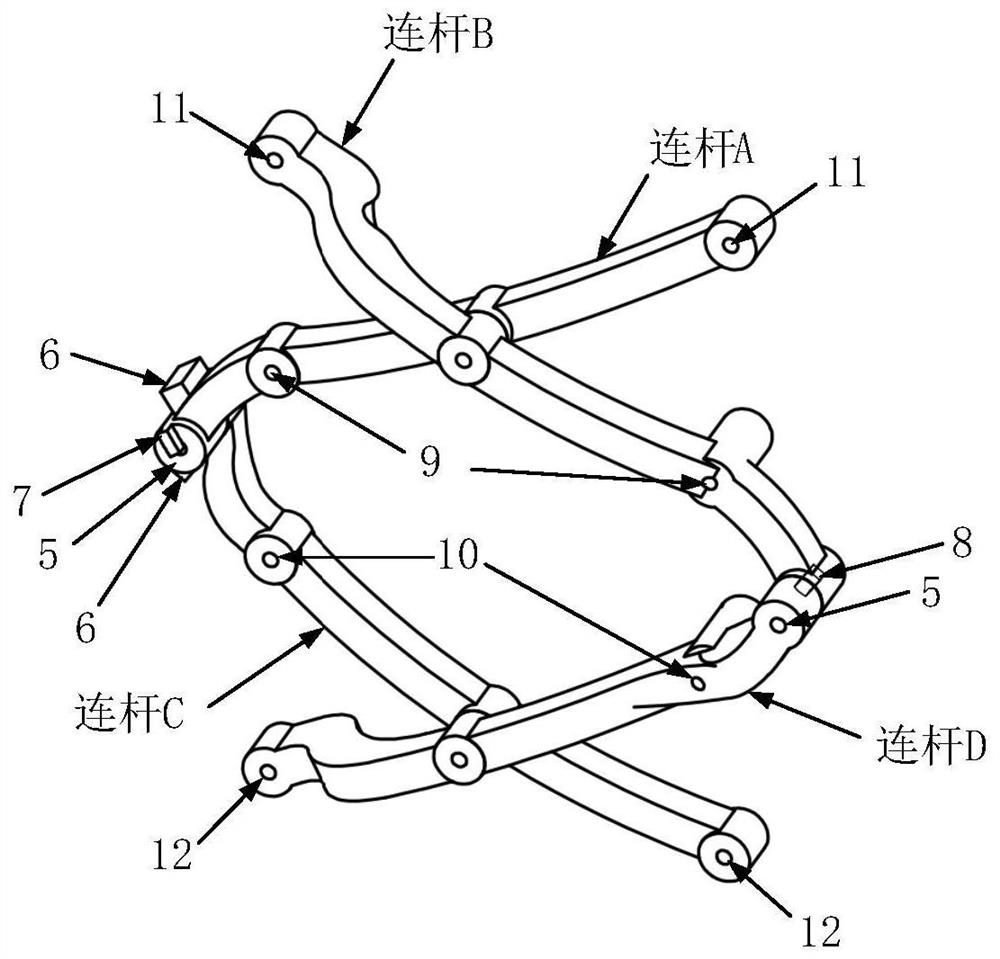

[0036] Such as figure 1 As shown, the reconfigurable folding mechanism for pipeline environment operation is mainly composed of three parts, including a pair of metamorphic scissor mechanisms 1 at the front and rear, two pairs of auxiliary scissor mechanisms 2 on the left and right sides, and a pair of metamorphic scissor mechanisms for connecting The connection part 3 of the fork mechanism 1 and the auxiliary scissor mechanism 2.

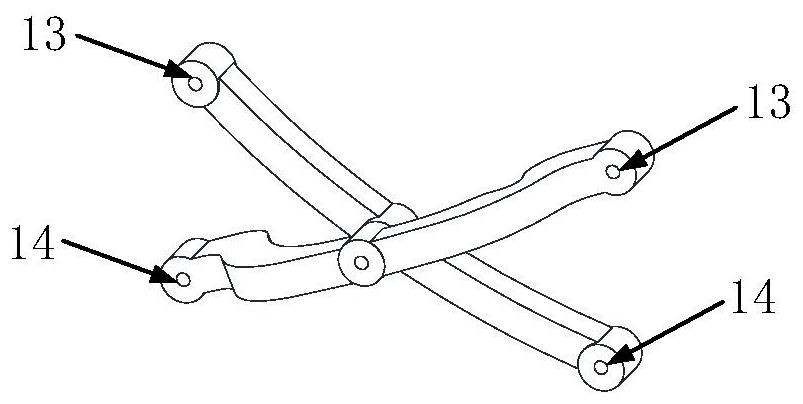

[0037] The modified scissors mechanism 1 and the auxiliary scissors mechanism 2 are both composed of multiple connecting rods, and the profile of each connecting rod is different from the general straight rod, but is designed to have an arc-shaped outer contour arc-shaped rods to better adapt to the environment of the inner wall of the pipeline; and in the overall configuration of the metamorphic scissors mechanism 1 and the auxiliary scissors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com