Energy-saving vacuum pump of automobile

A vacuum pump and automobile technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of increasing the energy consumption of the engine and increasing the energy consumption of the vacuum pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

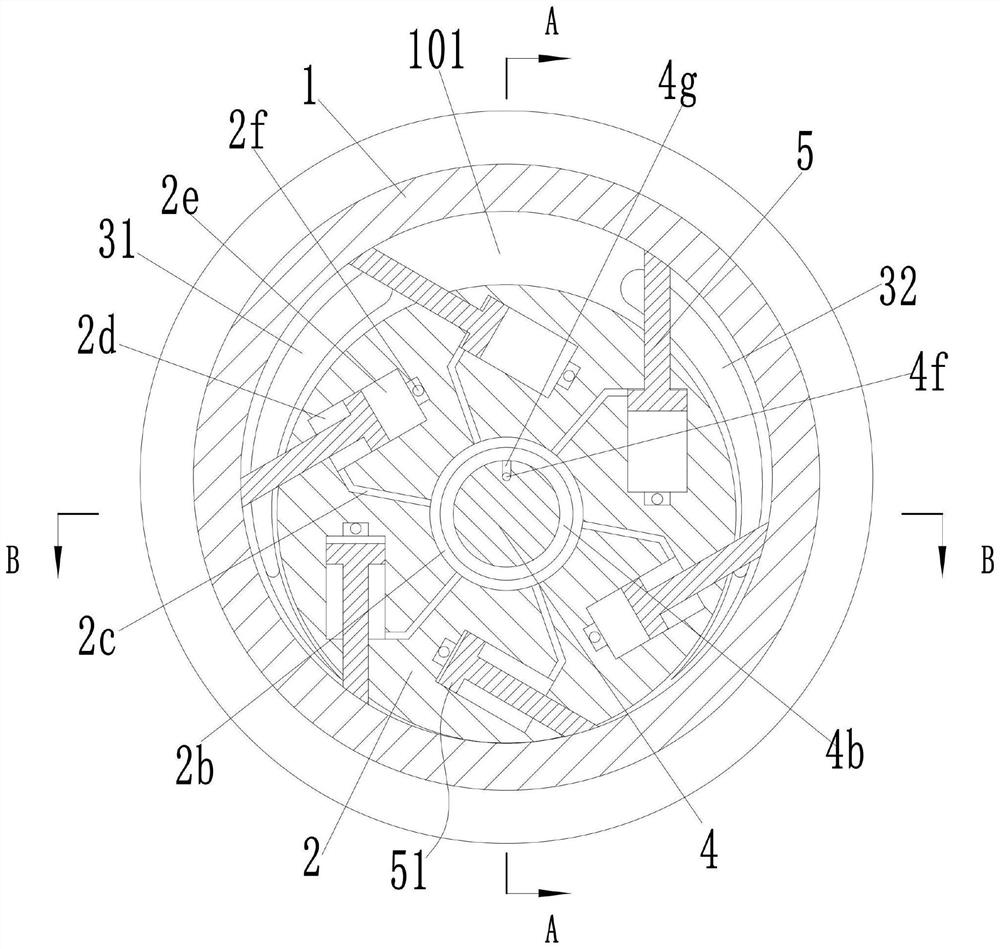

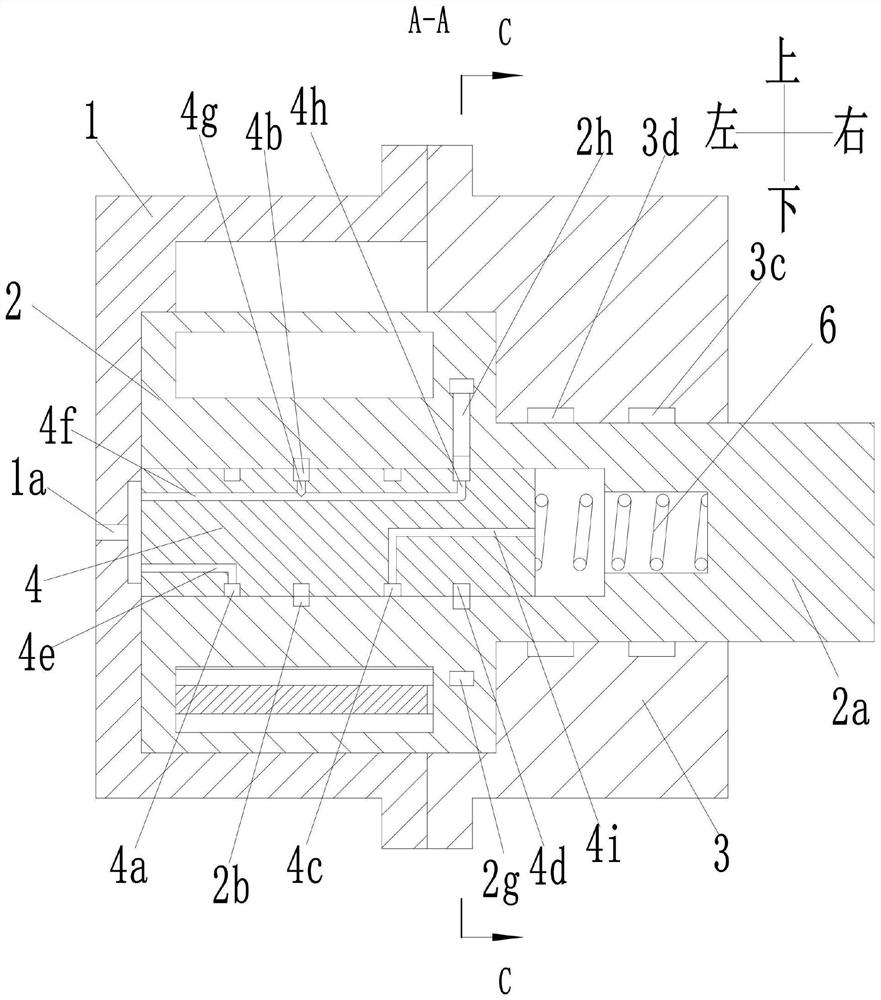

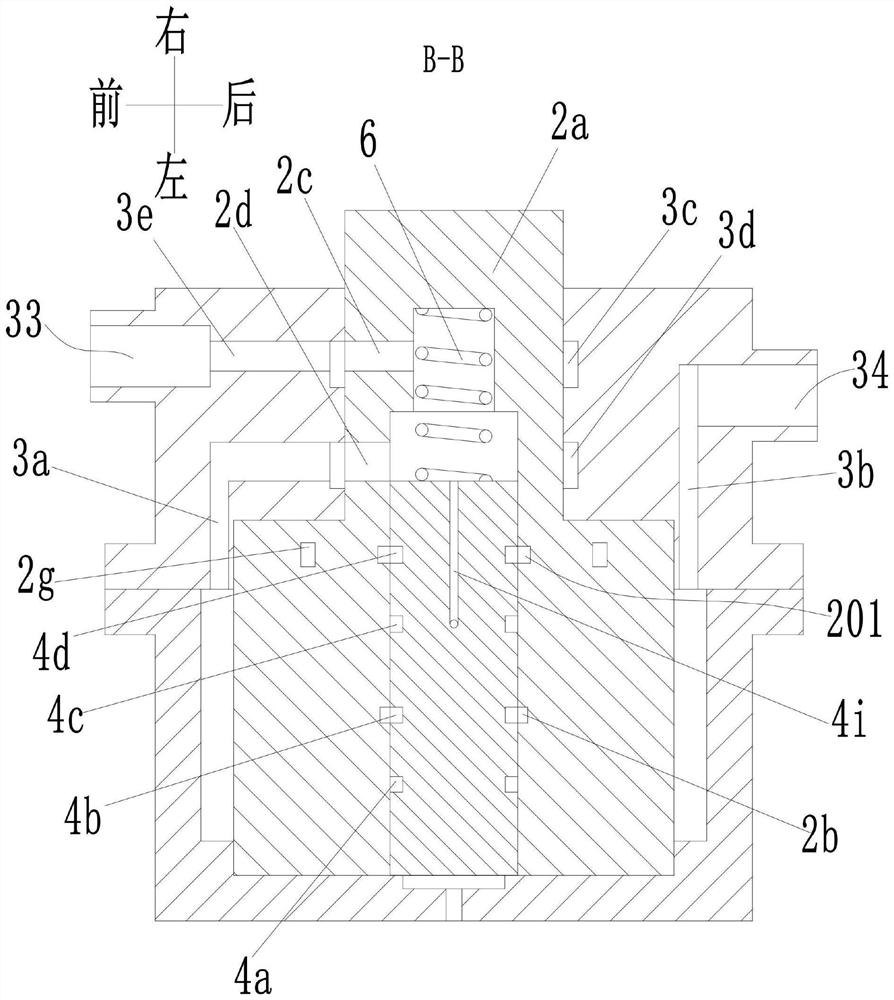

[0023] see Figure 1-7 As shown, an automobile energy-saving vacuum pump includes a pump body 1, a pump chamber 101 with an opening at the right end is arranged in the pump body 1, and an end block 3 is fixedly installed at the opening of the right end of the pump chamber 101 in the pump body 1. A rotor 2 is rotationally connected between the left end of the pump chamber 101 and the end block 3, and the rotor 2 is eccentrically arranged in the pump chamber 101; the right end of the rotor 2 is extended with a rotating shaft 2a protruding from the end block 3, The rotating shaft 2a and the rotor 2 are in a coaxial position; the rotor 2 is evenly provided with a plurality of chute 202 along the circumferential direction, and each chute 202 is slidably connected with a slider 51, and each slider 51 The vanes 5 for extending out of the rotor 2 are extended on the top, and the pump chamber 101 is provided with suction grooves 31 and air outlet grooves 32 symmetrically on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com