Double-path vertical extrusion type peristaltic pump

A vertical extrusion and peristaltic pump technology, applied in the field of peristaltic pumps, can solve problems affecting flow stability and accuracy, flow error, and application occasions that are difficult to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description of embodiments and drawings of the present invention, by binding certain specific examples, those skilled in the art may be disclosed in the present specification easily understand other advantages and effects of the present invention. The present invention can also be practiced or applied by other different specific examples, the details of the specification may also, that various changes and modifications without departing from the spirit of the invention based on various concepts and applications.

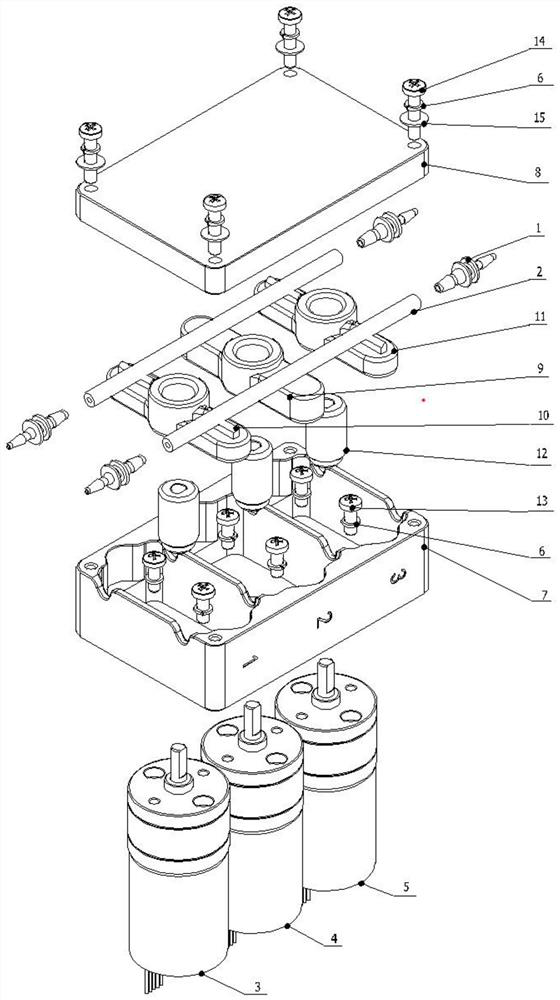

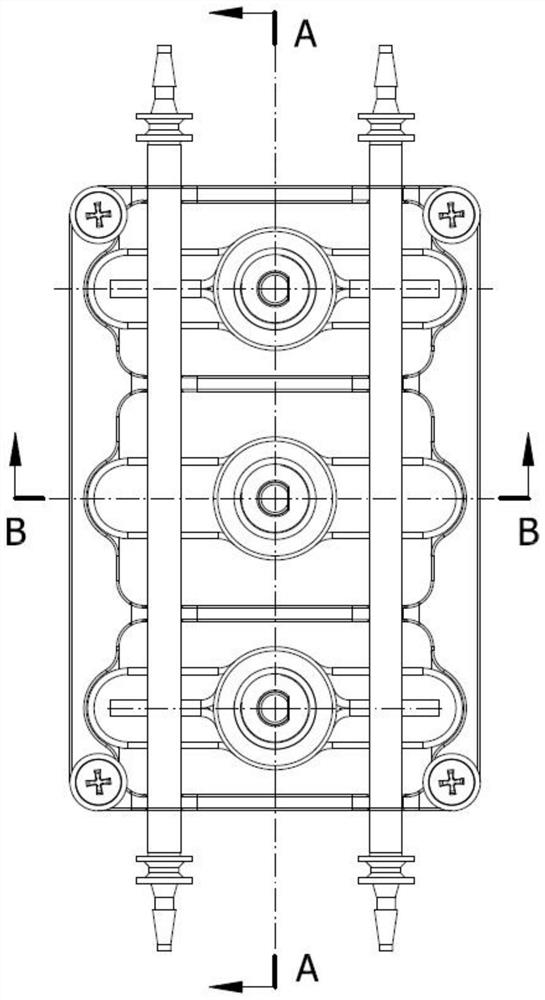

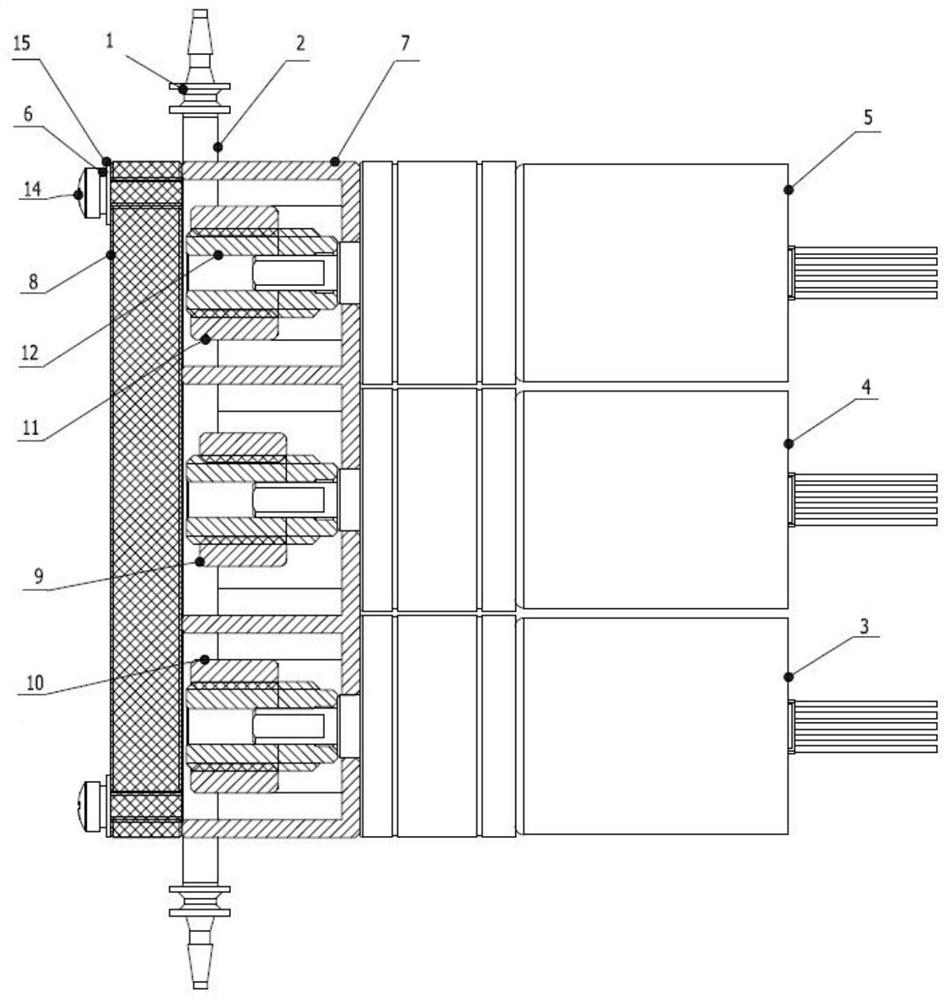

[0030] The present invention provides a vertical two-way squeeze type peristaltic pump, according to Figure 1 - Figure 4 , Includes a pump head 7, the head 7 is provided with two rubber tube guide groove, and said guide groove with a rubber tube 2 is mounted; said head 7 is provided with a second intermediate threshold nubs positioning groove, the lower groove provided with a first switching block limit, the upper limit switch block provided with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com