Wedge-shaped unloading device for bent cap supporting system

A support system and wedge-shaped technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as difficult demolition and low accuracy of elevation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

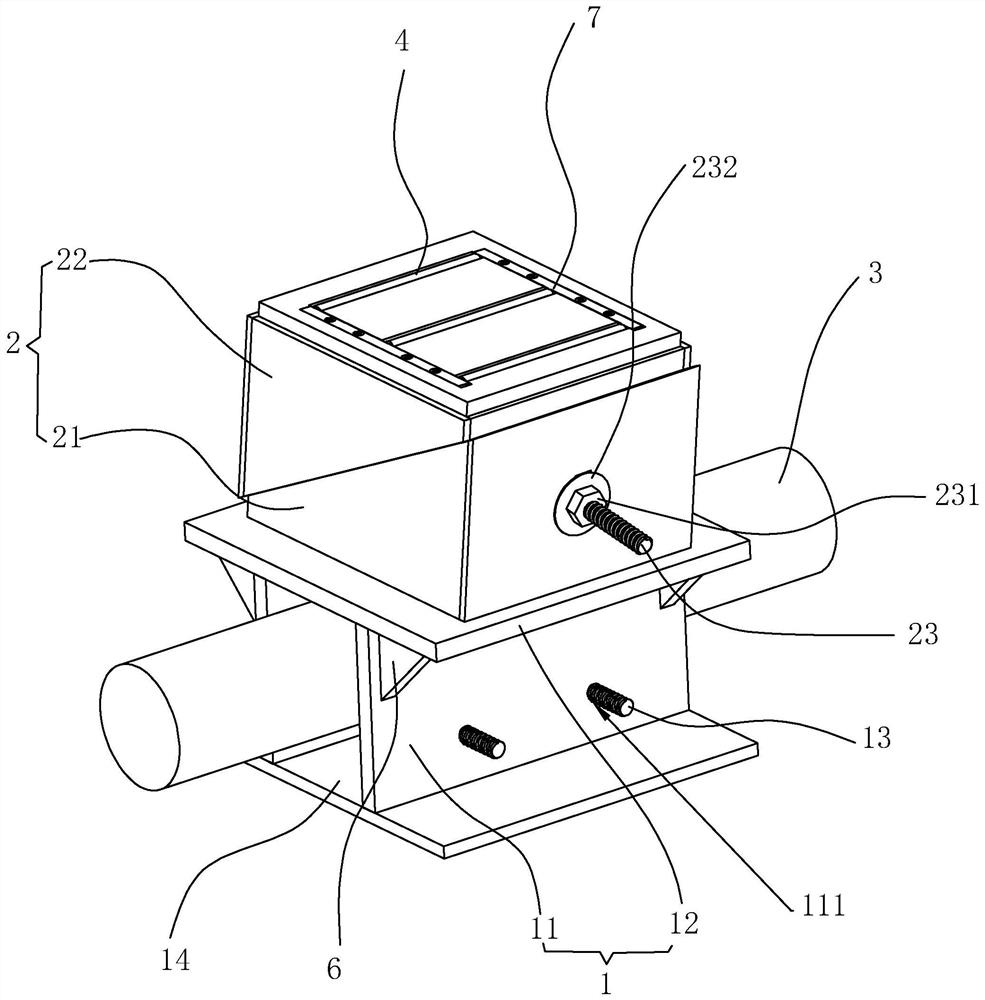

[0032] The following is attached Figure 1-2 The application is described in further detail.

[0033] The embodiment of the present application discloses a wedge-shaped unloading device for a cover beam support system. refer to figure 1The wedge-shaped unloading device for the support system of the cover beam includes a base 1 and a sliding module 2. The base 1 includes two sets of vertical support side plates 11 and a flat plate 12 located at the upper ends of the two sets of support side plates 11. The upper end of the group of supporting side plates 11 is fixedly connected with the lower end surface of the flat plate 12; Several groups of cross bars 13 on the same level are installed between the groups of supporting side plates 11, preferably 2 groups here, the two ends of the cross bar 13 are threaded structures, and the two ends of the cross bar 13 are threadedly connected with each group of threaded holes 111 . A piercing rod 3 is inserted between each group of cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com