On-line surfacing device and online surfacing method for cone rollers of ring rolling machine

A technology of ring rolling machine and tapered roller is applied in the field of on-line surfacing welding of tapered rollers of ring rolling machine and on-line surfacing welding device of tapered rollers of ring rolling machine. , The effect of reducing maintenance costs and simple structure

Active Publication Date: 2022-05-31

ZHUZHOU TIANLI FORGING IND

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the prior art, maintenance personnel are required to first remove the tapered roller from the equipment, install the tapered roller on a lathe or other auxiliary tooling, use a welding torch to carry out surfacing welding on it, and then put it back into the rolling ring after repairing machine, in which the disassembly and assembly of the tapered rollers has the disadvantage of taking a long time, which in turn leads to an increase in repair time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] Specifically, the welding torch 3 is a gas shielded welding torch. Because the gas shielded welding torch has the advantages of stable wire feeding

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

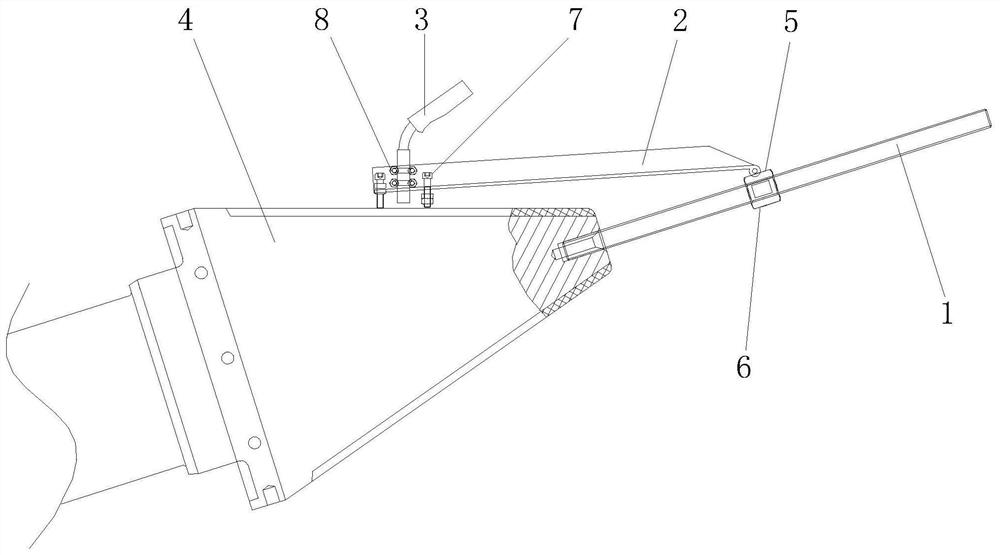

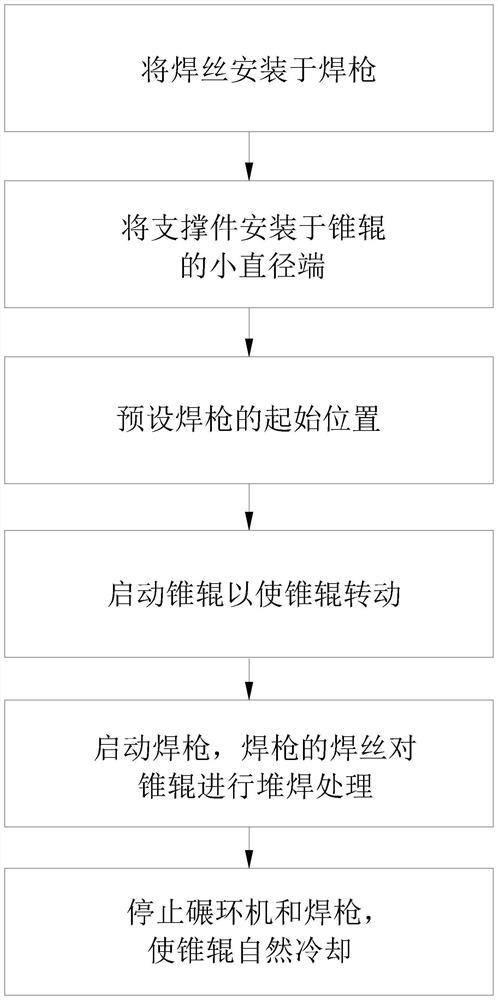

The invention provides an on-line surfacing device for cone rollers of a ring rolling machine, which includes a support piece, a connecting piece and a welding torch. The support piece is installed on the small diameter end of the cone roller and rotates synchronously with the cone roller. Installed on the support and move linearly along the support under the rotation of the support, the other end of the connecting piece extends to the surfacing position of the tapered roller, the welding torch is installed on the One end of the connecting piece is far away from the supporting piece, and its spray head faces the surfacing position of the tapered roller. In the technical solution of the present invention, the support is installed on the cone roller and rotates synchronously with the cone roller, and the driving connecting piece can move linearly along the support, so that the welding torch can move linearly along the generatrix direction of the cone roller, without the need to move the cone roller It is disassembled from the ring rolling machine and installed on a lathe or other auxiliary tooling, so that the outer wall of the tapered roller can be automatically welded online, which shortens the repair time.

Description

On-line surfacing device and on-line surfacing method for tapered rollers of ring rolling machine technical field The present invention relates to the repairing technical field of ring rolling machines, in particular to a kind of on-line surfacing device of the tapered rollers of a ring rolling machine and a kind of On-line surfacing method of tapered roller of ring rolling machine. Background technique The rolling of the workpiece by the ring rolling machine is realized by two tapered rollers, and the tapered rollers belong to the easy-to-wear parts, and the wear is excessive. It will lead to the problem that the machining accuracy of the ring is reduced and the end face of the ring is not flat, so the tapered roller is about every six months. Time to make a repair. Since the small diameter end of the tapered roll is used more frequently than the large diameter end, the small diameter end is ground The wear is more severe than that of the large diameter end, so the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K9/04B23K9/12B23K9/16

CPCB23K9/044B23K9/12B23K9/16Y02P70/10

Inventor 熊勇军郑业方罗彦云朱志斌杨晴

Owner ZHUZHOU TIANLI FORGING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com