Environment-friendly fly ash treatment equipment for coal chemical industry production

A kind of processing equipment and environment-friendly technology, which is applied in the field of environment-friendly fly ash processing equipment for coal chemical production, which can solve the problems of fly ash flying, taking a long time, troublesome collection and cleaning of fly ash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

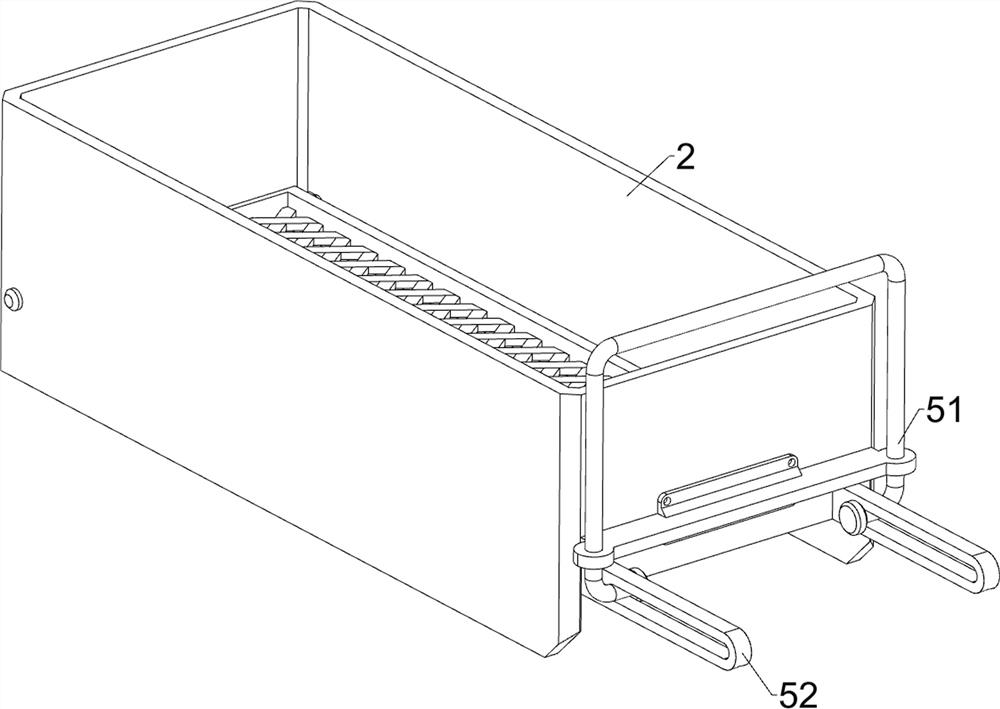

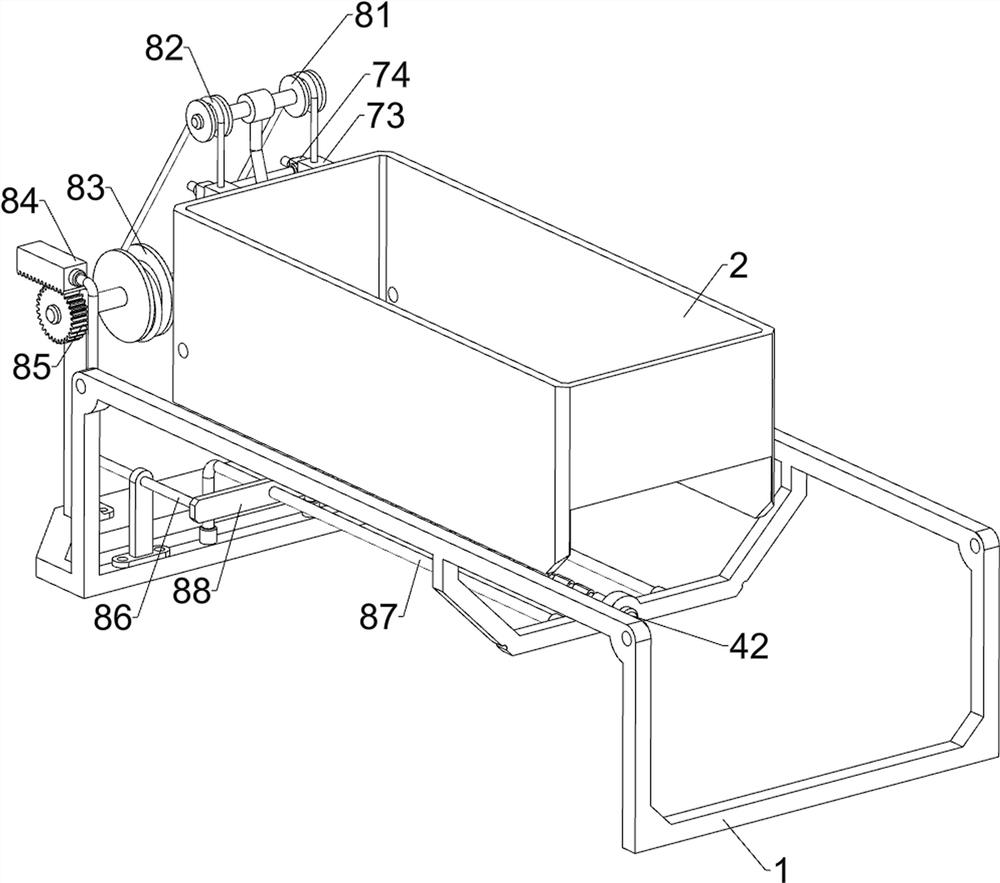

[0028] An environment-friendly fly ash processing equipment for coal chemical production, such as Figure 1 to Figure 4 As shown, it includes a frame 1, a frame 2, a first spring 3, a driving assembly 4, a screening assembly 5 and a blocking assembly 6. The frame 1 is slidably provided with a frame 2, and the frame 1 and the front part of the frame 2 are left and right. Both sides are connected with a first spring 3 , a driving assembly 4 is provided between the frame 1 and the frame 2 , a screening assembly 5 is provided on the frame 2 , and a blocking assembly 6 is provided on the frame 1 .

[0029] When it is necessary to process the fly ash, the burnt briquettes are placed in the frame 2, and then the drive assembly 4 is started, and the drive assembly 4 will drive the frame 2 to move, and the frame 2 will continue to move through the action of the first spring 3 The reciprocating movement makes the burnt briquettes shake, so that the fly ash on the surface of the briquett...

Embodiment 2

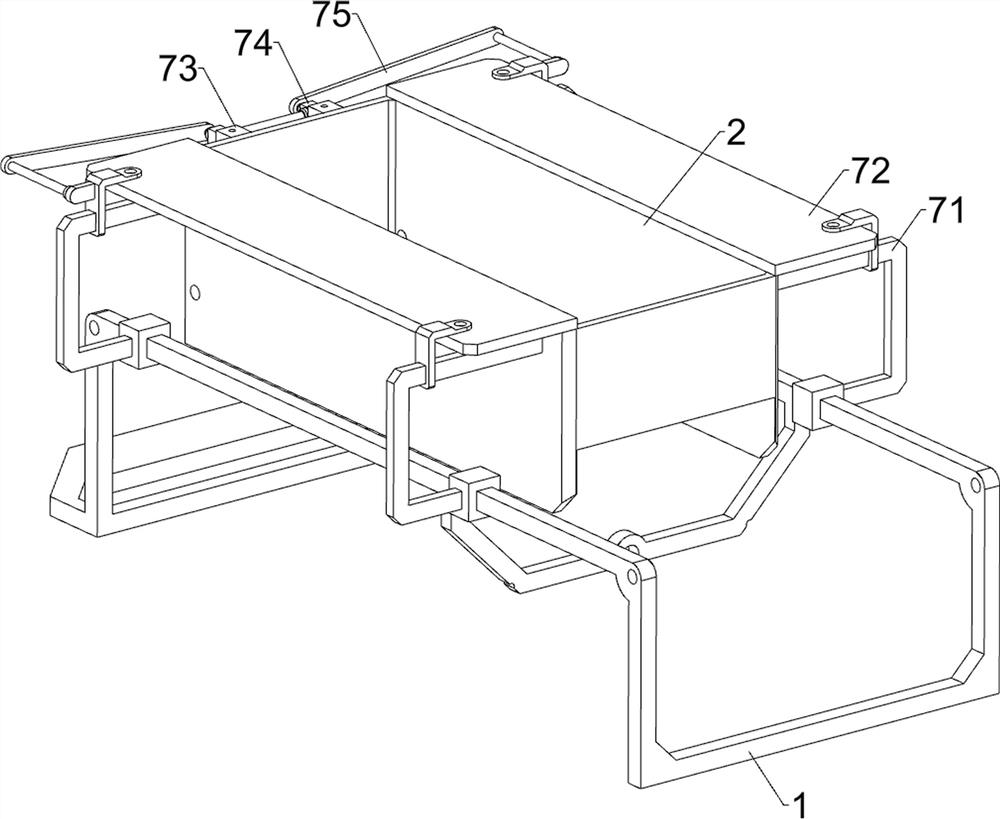

[0037] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 and Figure 7As shown, it also includes a cover assembly 7, the cover assembly 7 includes a guide plate 71, a cover plate 72, a second slide rail 73, a second slide block 74 and a pull plate 75, between the left and right sides of the frame 1 and the frame 2 Guide plates 71 are provided between them, cover plates 72 are slidably arranged on the guide plates 71, second slide rails 73 are provided on the left and right sides of the rear of the frame 2, and second slide rails 73 are all slidably provided on the second slide rails 73. Elastic parts are provided between the second slide block 74 , the second slide rail 73 and the second slide block 74 , and pull plates 75 are rotatably connected between the second slide block 74 and the cover plate 72 .

[0038] When the fly ash needs to be processed, the second slider 74 is controlled to move upward, and the elastic member is deformed, and then the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com