Method for reducing nitrogen and increasing sugar of upper leaves

A nitrogen and sugar reduction technology, applied in the fields of tobacco, food science, and tobacco preparation, can solve the problems that the amount of aroma components cannot be directly controlled, the quality of tobacco leaves is different, and the production efficiency of tobacco leaves cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

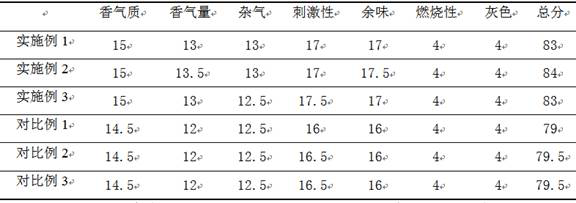

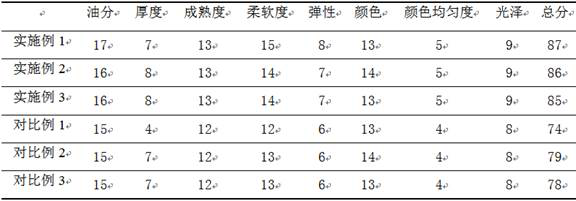

Examples

Embodiment 1

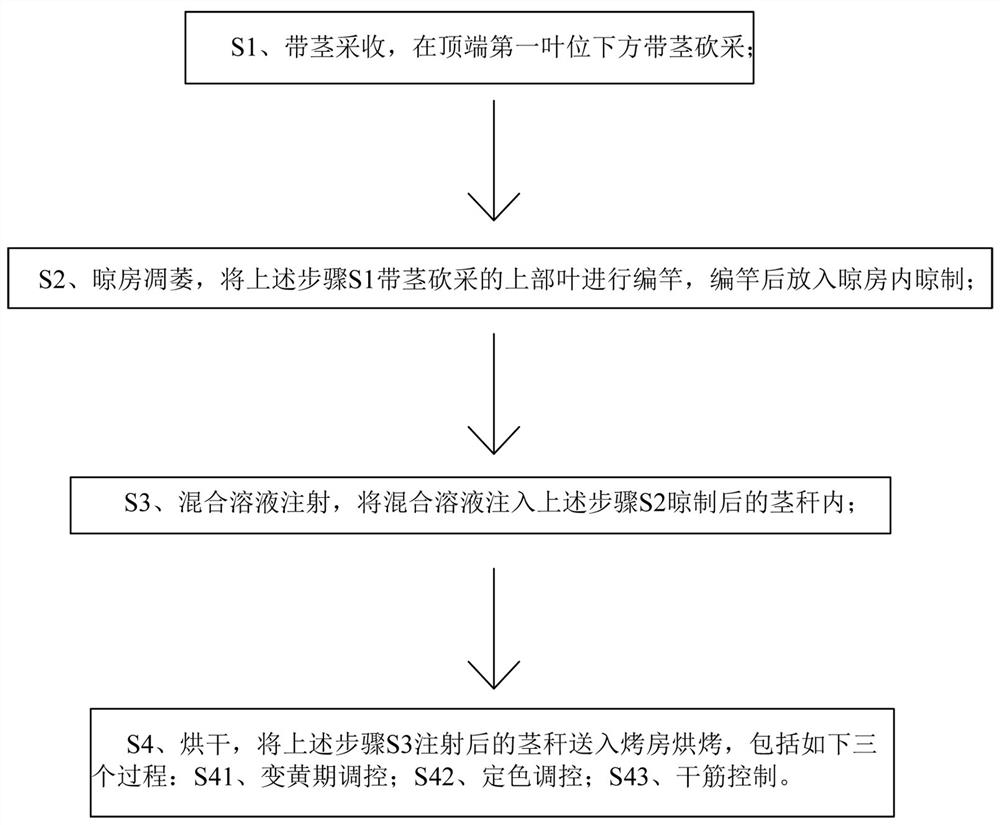

[0037] A method for lowering nitrogen and increasing sugar in upper leaves, specifically as follows:

[0038] S1. Harvesting with stems: 4 tobacco leaves in the upper part of the field, 90% of the third leaf position turns yellow, the main vein turns white and shiny, the angle between the stem and leaf is 55°, the tip and edge of the leaf are slightly curled, and the distance from the first leaf position ( Counting from bottom to top) at 9cm, cut and harvest with stems;

[0039] S2, withering in the airing room: the upper leaves cut with stems are taken as a group of 30 plants, and the poles are weaved, and put into the airing room after weaving the poles to dry for 3 days, so that the tobacco leaves lose water and wither;

[0040]S3. Mixed solution injection: inject the prepared mixed solution into the dried stems. The mixed solution contains glucose, potassium carbonate and papain, the contents of which are respectively 5%, 3% and 0.1% of the total mass, and the balance is ...

Embodiment 2

[0046] A method for lowering nitrogen and increasing sugar in upper leaves, specifically as follows:

[0047] S1. Harvesting with stems: 5 tobacco leaves in the upper part of the field, 90% of the third leaf position turns yellow, the main vein turns white and shiny, the angle between the stem and leaf is 60°, the tip and edge of the leaf are slightly curled, and the distance from the first leaf position ( Counting from bottom to top) at 10cm, cut with stems;

[0048] S2, withering in the airing room: the upper leaves with stems cut and collected are taken as a group of 30 plants, and the poles are weaved, and put into the airing room after weaving the poles to dry for 4 days, so that the tobacco leaves are dehydrated and withered;

[0049] S3. Mixed solution injection: inject the prepared mixed solution into the dried stems. The mixed solution contains sucrose, potassium carbonate and papain, the contents of which are respectively 8%, 5% and 0.3% of the total mass, and the b...

Embodiment 3

[0055] A method for lowering nitrogen and increasing sugar in upper leaves, specifically as follows:

[0056] S1. Harvesting with stems: 6 tobacco leaves in the upper part of the field, 90% of the third leaf position turns yellow, the main vein turns white and shiny, the angle between the stem and leaf is 65°, the tip and edge of the leaf are slightly curled, and the distance from the first leaf position ( Counting from bottom to top) at 11cm, cut with stems;

[0057] S2, withering in the airing room: the upper leaves with the stems cut and collected are taken as a group of 30 plants, and the poles are weaved, and put into the airing room after weaving the poles to dry for 5 days, so that the tobacco leaves are dehydrated and withered;

[0058] S3. Mixed solution injection: inject the prepared mixed solution into the dried stems. The mixed solution contains starch, potassium carbonate and papain, the contents of which are respectively 10%, 6% and 0.5% of the total mass, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com