Yarn online continuous drying equipment and process

A yarn drying technology, applied in progressive dryers, drying solid materials, drying gas arrangement, etc., can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

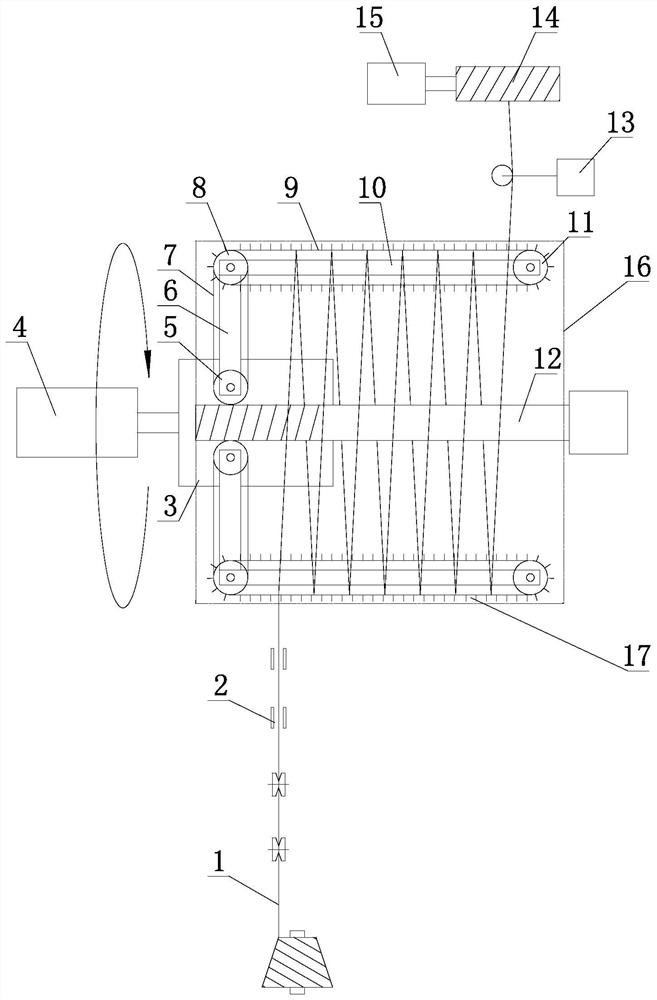

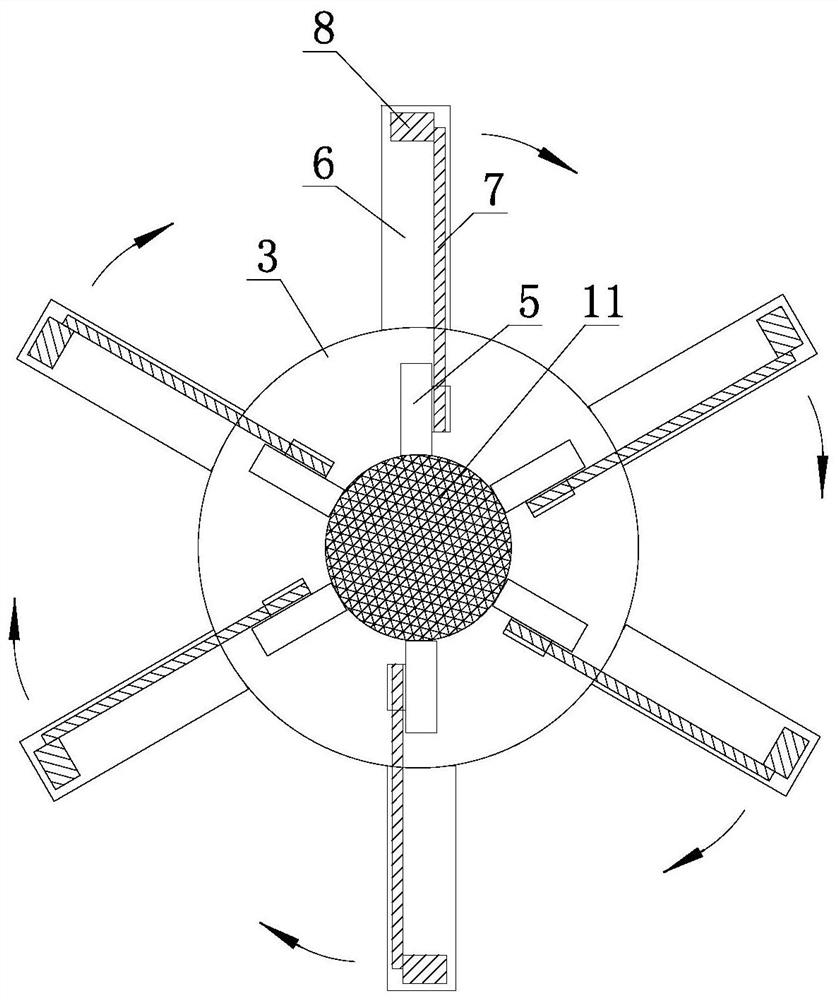

[0031] Such as Figure 1~2 As shown, the equipment for continuous drying of yarns on-line according to the present invention includes a tumbler 16, and a yarn output device is connected in front of the tumbler 16; the outer periphery of the tumbler 16 is distributed with a number of traversing belts 9 moving in the same direction, and the single yarn 1 After coming out of the yarn output device, it is coiled around the outer circumference of the tumbler 16 to follow the rotation of the tumbler 16 , and the single yarn 1 is continuously moved laterally along the axial direction of the tumbler 16 under the action of the traversing belt 9 .

[0032] The yarn storage device is connected behind the tumbler 16, and the single yarn 1 is wound on the yarn storage device 14 after being removed from the tumbler 16. The yarn storage device includes a yarn storage device 14 and a yarn storage device motor 15, the yarn storage device 14 is connected to the yarn storage device motor 15, and...

Embodiment 2

[0041] After the package yarn dyeing, the moisture content of 40 pure cotton dyed package yarns is 187%, the room temperature is 22°C, and the air humidity is 50%.

[0042] The yarn is wound on the yarn channel 17 of the tumbler 16 through the guide channel 2, the tumbler motor 4 is turned on, and the tumbler 16 rotates at the same time, the traversing belt 10 moves laterally so that the yarns are arranged in an orderly manner but not overlapped and wound on the tumbler 16 on. The yarn winding distance is 1 mm, the rotating speed of the rotating cage is 200 r / min, the yarn on the rotating cage is wound on the yarn passage 17 for 200 laps and then turned out, and the turned out yarn passes through the tension controller 13 and is wound on the yarn storage device On 14, wind into a compact package with a suitable size and uniform density, and the density of the compact package is 0.45g / cm 3 .

[0043] The drying process is continuous, and the moisture content of the yarn after...

Embodiment 3

[0045] After the dyeing of the package yarn, the moisture content of the 21 dyed package yarns of flax is 230%, the room temperature is 25°C, and the air humidity is 55%.

[0046] The yarn is wound on the yarn channel 17 of the tumbler 16 through the guide channel 2, the tumbler motor 4 is turned on, and the tumbler 16 rotates at the same time, the traversing belt 10 moves laterally so that the yarns are arranged in an orderly manner but not overlapped and wound on the tumbler 16 on. The yarn winding distance is 0.8 mm, the rotating speed of the tumbler is 300 r / min, the yarn on the tumbler is wound on the yarn channel 17 for 400 laps and then turned out, and the turned out yarn passes through the tension controller 13 and is wound on the yarn storage On the device 14, the tight bobbin of suitable size and uniform density is wound, and the density of the tight bobbin is 0.48g / cm 3 .

[0047] The drying process is continuous, and the moisture content of the yarn after drying is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com