Blockage clearing device for screw conveyor

A screw conveyor and blockage removal technology, which is applied to cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity and long time for blockage removal, and achieve power saving, simple structure, and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

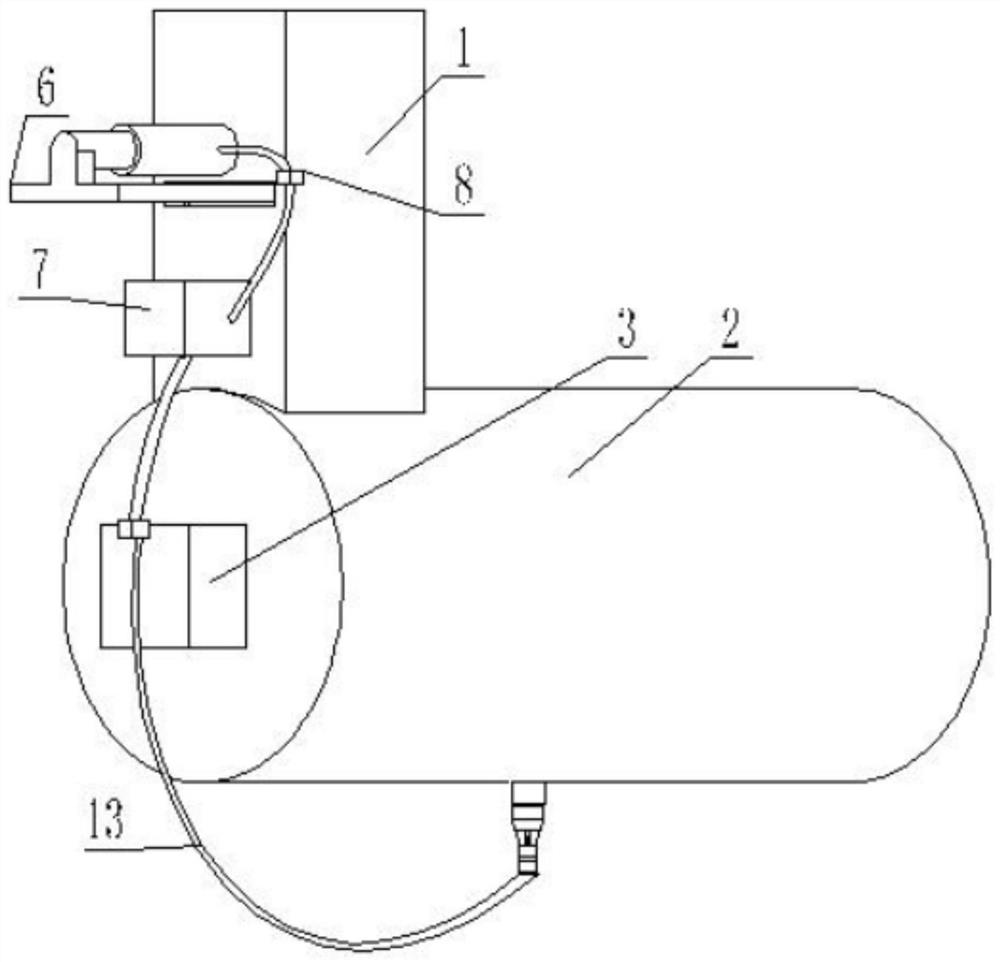

[0034] A screw conveyor clearing device, such as Figure 1-2 As shown, it includes a feeding pipe 1 and a conveying assembly. The feeding pipe 1 is provided with a pneumatic slide valve 6 and an external air source 7. The air source 7 provides power to the pneumatic slide valve 6, and the pneumatic slide valve The valve 6 is used to close the feeding pipe 1 .

[0035] The conveying assembly includes a housing 2, a motor 3, a rotating shaft 4 and a feeding blade 5, the rotating shaft 4 is installed in the housing 2, the rotating shaft 4 is provided with a feeding blade 5, and one side of the housing 2 is provided for driving rotation. The shaft 4 rotates the motor 3, and the side of the housing 2 away from the motor 3 is provided with a discharge port. The motor 3 drives the rotating shaft 4 and the feeding blade 5 to rotate, so as to move the material toward the discharge port.

[0036] The motor 3 is connected to the peripheral controller, and the controller judges the oper...

Embodiment 2

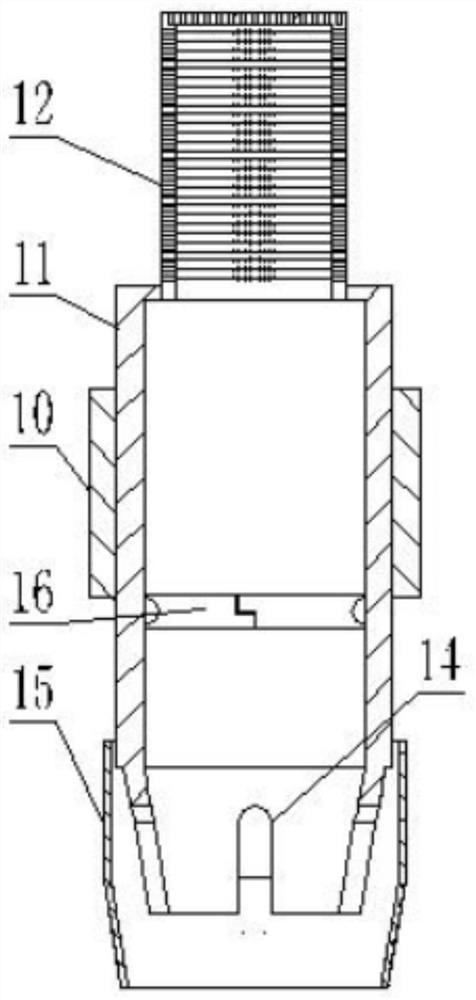

[0050] On the basis of Embodiment 1, two mutually matching sealing plates 16 are movably installed on one end of the installation head 11 close to the filter screen 12, the inner end of the sealing plate 16 is provided with a groove, and the inner end of the other sealing plate 16 is There are convex parts matched with it. The sealing plate 16 maintains a closed state under its own weight, and seals and isolates the interior of the installation head 11, so that the sealing performance of the device can be ensured and material leakage can be prevented when no blockage removal operation is performed.

[0051] An annular support rod 17 is provided at one end of the connecting pipe, and a push rod 18 for lifting the sealing plate 16 is provided on the support rod 17 . Intake pipe 13 inside is provided with support rod 17 and ejector rod 18, and support rod 17 can increase the support strength of connecting pipe, facilitates intake pipe 13 to be inserted on the mounting head 11, av...

Embodiment 3

[0055] On the basis of Embodiment 1 and Embodiment 2, the air intake pipe 13 is provided with a first mark 19 and a second mark 20 . When the user can see that the first mark 19 is located on the lower side of the installation head 11, it means that the air intake pipe 13 is only connected to the installation head 11, but it is not in an effective connection state for the cleaning operation. It has a storage function but does not perform blockage removal operations.

[0056] When the user sees that the second mark 20 is located on the lower side of the installation head 11, it means that the air intake pipe 13 and the installation head 11 are in an effective connection state, and the blockage removal operation can be performed at this time. The mark can serve as a reminder, which is convenient for the staff to confirm the connection status between the intake pipe 13 and the installation head 11, and facilitates work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com