Clamping device

A clamping device and clamping technology, applied in the field of manipulators, can solve the problems of complex structure of transmission components, many parts and components, high cost, etc., and achieve the effect of simple matching method, low cost and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

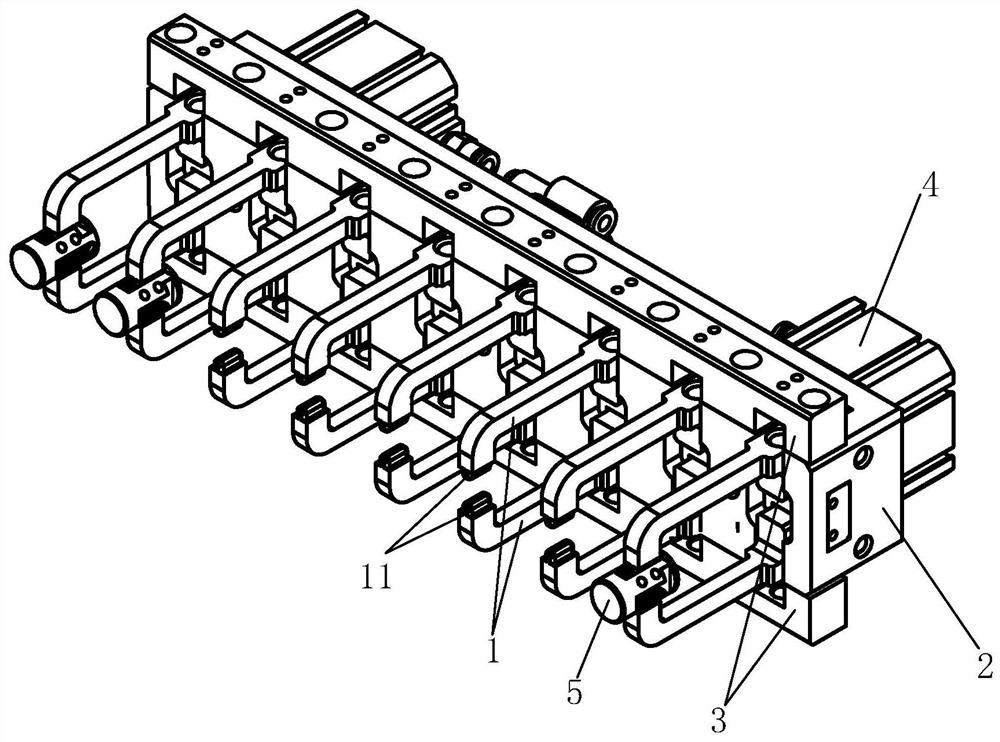

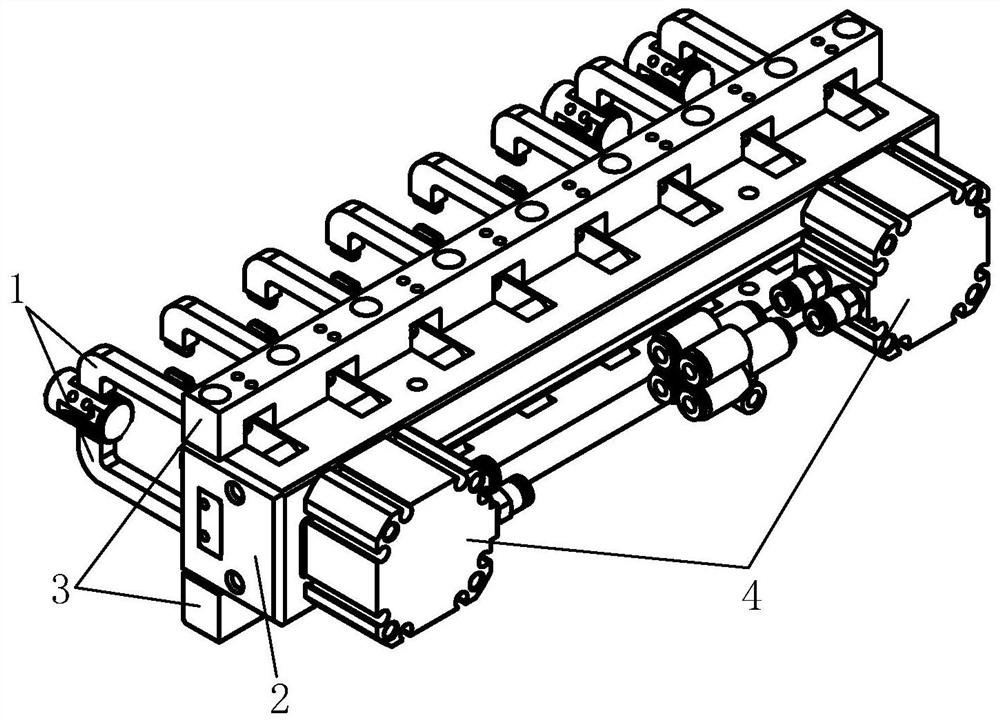

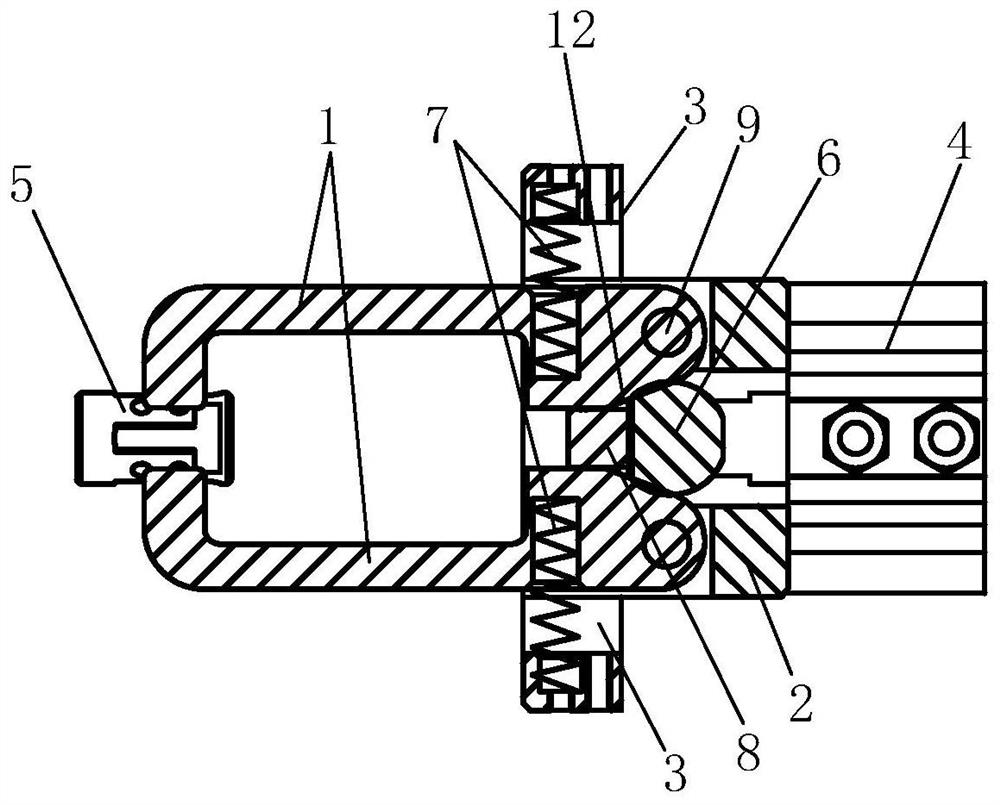

[0026] Examples, see Figure 1-Figure 4 As shown, a clamping device of the present invention includes a fixed body, a clamping unit, a power component, and a pusher 6. The clamping unit includes a plurality of clamping components distributed side by side, and each clamping component includes two clamping jaws 1 , the two jaws 1 are respectively rotatably connected to the fixed body, and the two jaws 1 are arranged oppositely; the power component is arranged on the fixed body, and pushes the two jaws 1 of each clamping part through the pusher 6 when starting, so that the two The clamping jaws 1 are used to separate one end of the clamping object from each other; the two clamping jaws 1 of each clamping part are respectively equipped with a reset part with the fixed body, or the two clamping jaws 1 of each clamping part are equipped with a reset part, and the reset The part drives the two jaws 1 to reset, so that the ends of the two jaws 1 for clamping the object are moved close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com