System for transforming TRT excitation field control into remote monitoring

A technology of on-site control and remote monitoring, applied in the field of TRT remote control, can solve problems such as inability to adapt to industrial control concepts, inability to realize remote centralized control, and inability to support 485 communication, so as to improve defects, enhance protection levels, and alleviate dangers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

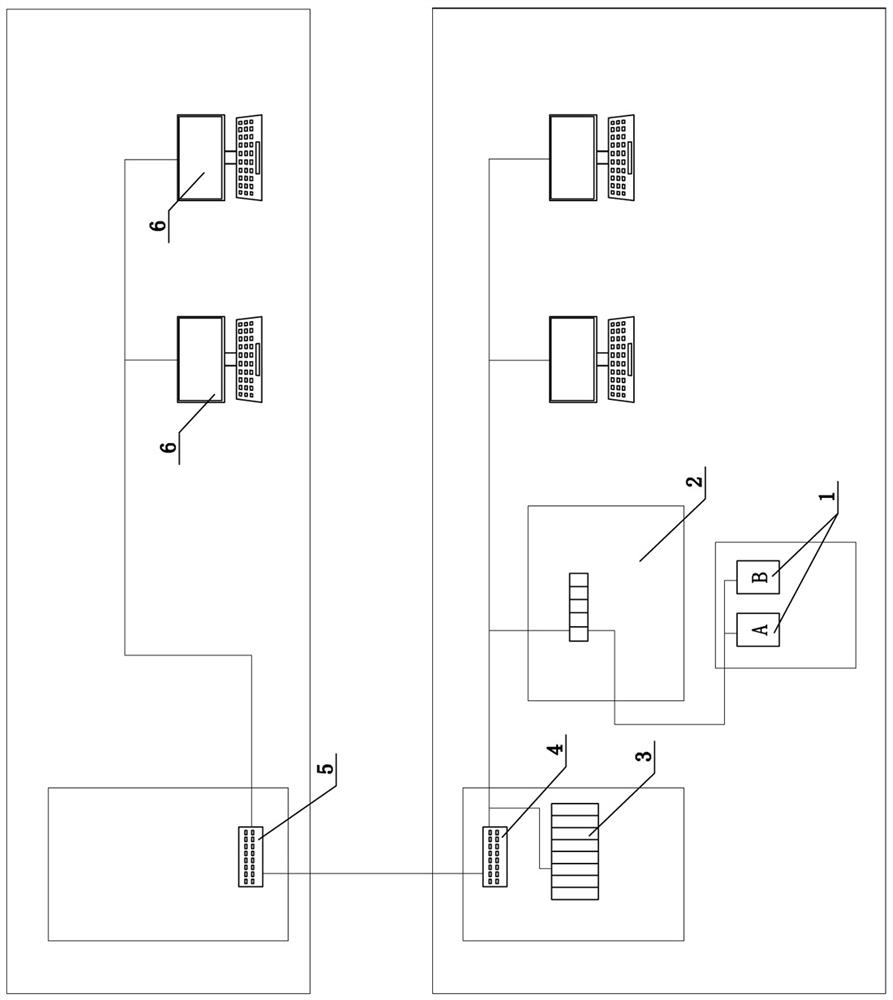

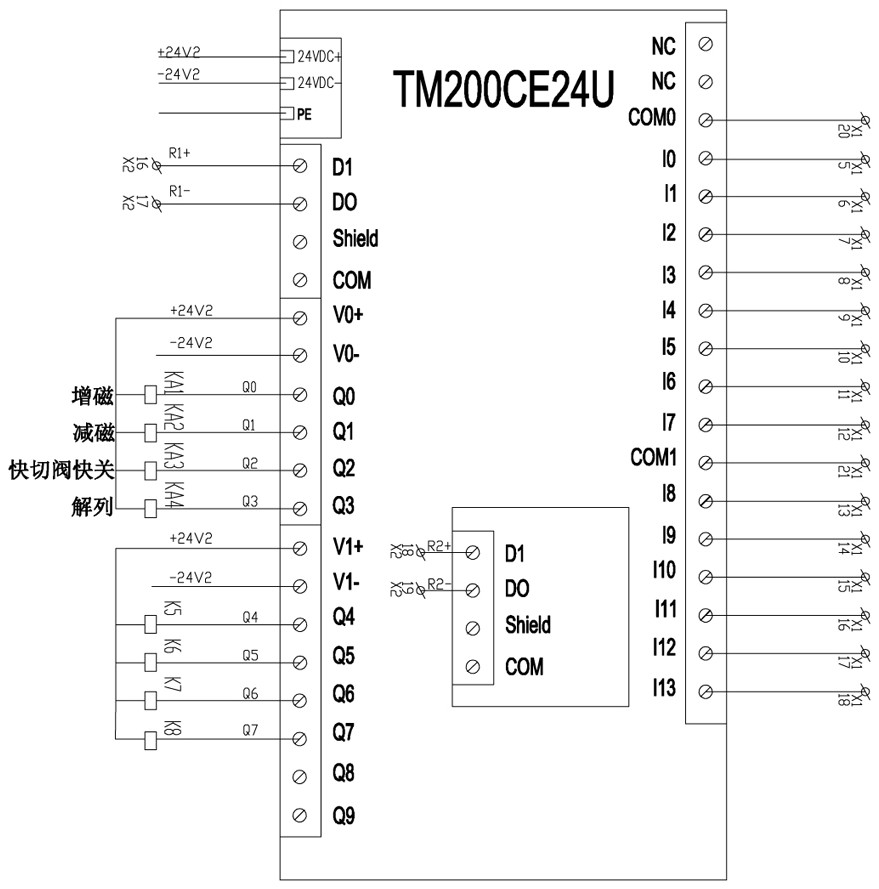

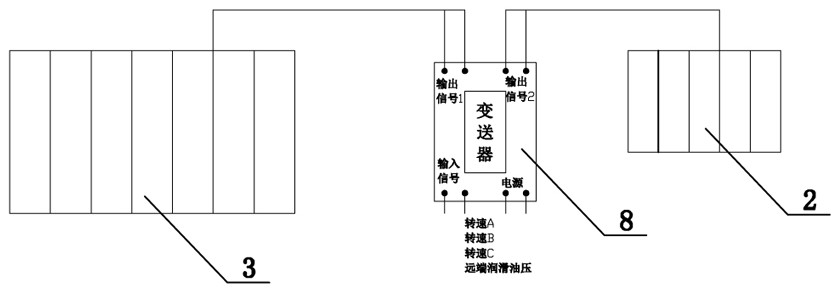

[0018] see Figure 1-6 , this embodiment includes the original on-site PLC control cabinet 3 and the excitation controller 1, and a set of remote PLC centralized control cabinet 2 is added on the basis of the original control system, which has RS485 communication function and supports Modbus-RTU communication protocol. It also supports TCP / IP communication protocol. On the one hand, it is connected to the excitation controller through the RS485 port to obtain all the data and parameters of the excitation; on the other hand, it is connected to the same data switch with the on-site PLC control cabinet 3 of TRT through the RJ-45 port , in the same network segment on the hardware layer and the application layer, so as to have the basis for mutual communication. The PLCs on site are all selected from Schneider PLC. In order to ensure compatibility, the PLC in the remote PLC centralized control cabinet 2 is selected from Schneider TM200CE24U.

[0019] The remote PLC centralized con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com