Ultrathin condom formula and production process thereof

A production process and condom technology, applied in the field of ultra-thin condom formula and its production process, can solve the problems of thickness, safety, stretch resistance, and durability, and achieve anti-aging performance and stability Good performance, improved overall comprehensive performance, and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

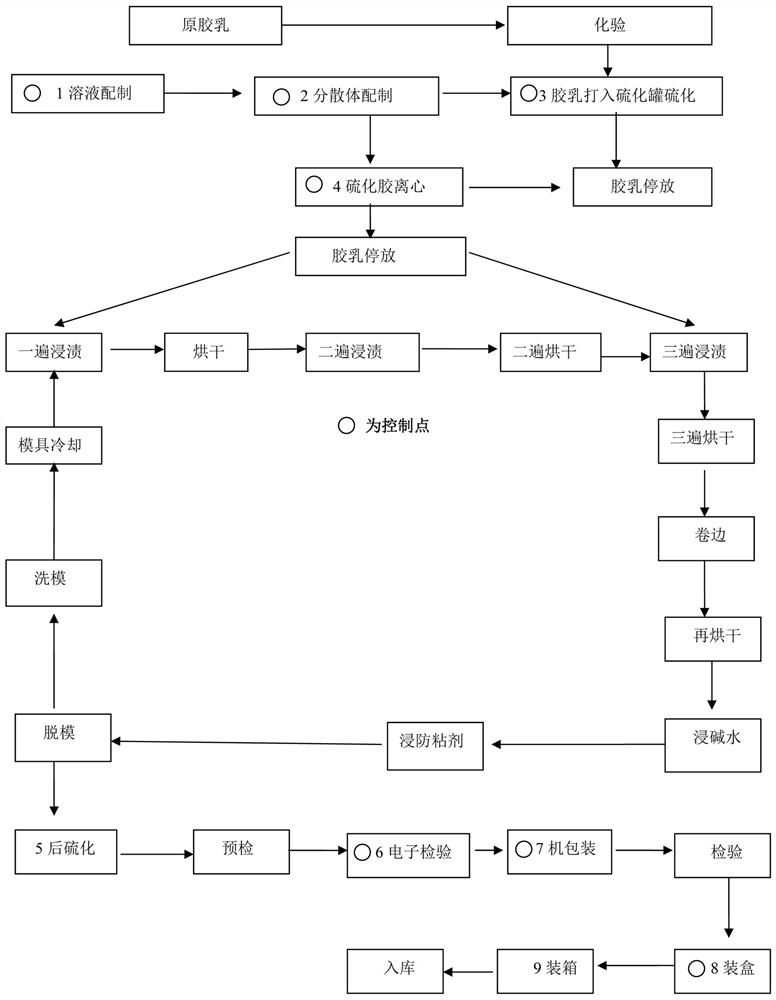

Method used

Image

Examples

Embodiment 1

[0198] An ultra-thin condom formula, comprising the following components in wet weight parts: 1000 parts of natural rubber latex, 12 parts of casein, 3 parts of diffusing agent NF, 8 parts of ammonia water, 5.6 parts of accelerator PX, and 1.6 parts of accelerator ZDC 15 parts, 15 parts of vulcanizing agent, 12.4 parts of active agent, 5 parts of antioxidant.

[0199] Preferably in any of the above schemes, the stabilizer includes the following components: casein, diffusion agent NF, ammonia water;

[0200] The accelerator includes the following components: accelerator PX, accelerator ZDC;

[0201] The vulcanizing agent includes the following components: sulfur;

[0202] The active agent includes the following components: zinc oxide;

[0203] The anti-aging agent includes the following components: anti-aging agent 264.

[0204]In any of the above schemes, it is preferred that the dry matter of the natural rubber latex accounts for 60% of the concentration, the casein of the...

Embodiment 2

[0209] An ultra-thin condom formula, comprising the following components in wet weight parts: 800 parts of natural rubber latex, 10 parts of casein, 1 part of diffusing agent NF, 6 parts of ammonia water, 3.6 parts of accelerator PX, and 0.6 parts of accelerator ZDC 10 parts, 10 parts of vulcanizing agent, 8.4 parts of active agent, 2 parts of anti-aging agent.

[0210] Preferably in any of the above schemes, the stabilizer includes the following components: casein, diffusion agent NF, ammonia water;

[0211] The accelerator includes the following components: accelerator PX, accelerator ZDC;

[0212] The vulcanizing agent includes the following components: sulfur;

[0213] The active agent includes the following components: zinc oxide;

[0214] The anti-aging agent includes the following components: anti-aging agent 264.

[0215] In any of the above schemes, it is preferred that the dry matter of the natural rubber latex accounts for 60% of the concentration, the casein of ...

Embodiment 3

[0217] An ultra-thin condom formula, comprising the following components in wet weight parts: 1200 parts of natural rubber latex, 14 parts of casein, 5 parts of diffusing agent NF, 10 parts of ammonia water, 7.6 parts of accelerator PX, and 2.6 parts of accelerator ZDC 20 parts, 20 parts of vulcanizing agent, 16.4 parts of active agent, 8 parts of antioxidant.

[0218] Preferably in any of the above schemes, the stabilizer includes the following components: casein, diffusion agent NF, ammonia water;

[0219] The accelerator includes the following components: accelerator PX, accelerator ZDC;

[0220] The vulcanizing agent includes the following components: sulfur;

[0221] The active agent includes the following components: zinc oxide;

[0222] The anti-aging agent includes the following components: anti-aging agent 264.

[0223] In any of the above schemes, it is preferred that the dry matter of the natural rubber latex accounts for 60% of the concentration, the casein of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com