Bypass sealing supporting rubber block

A rubber block and integrated technology, which is applied in the sealing of engines, engine components, mechanical equipment, etc., can solve problems such as insufficient sealing, high cost, and easy deformation, and achieve wide sealing range, reduce product shaking, and reduce parts displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

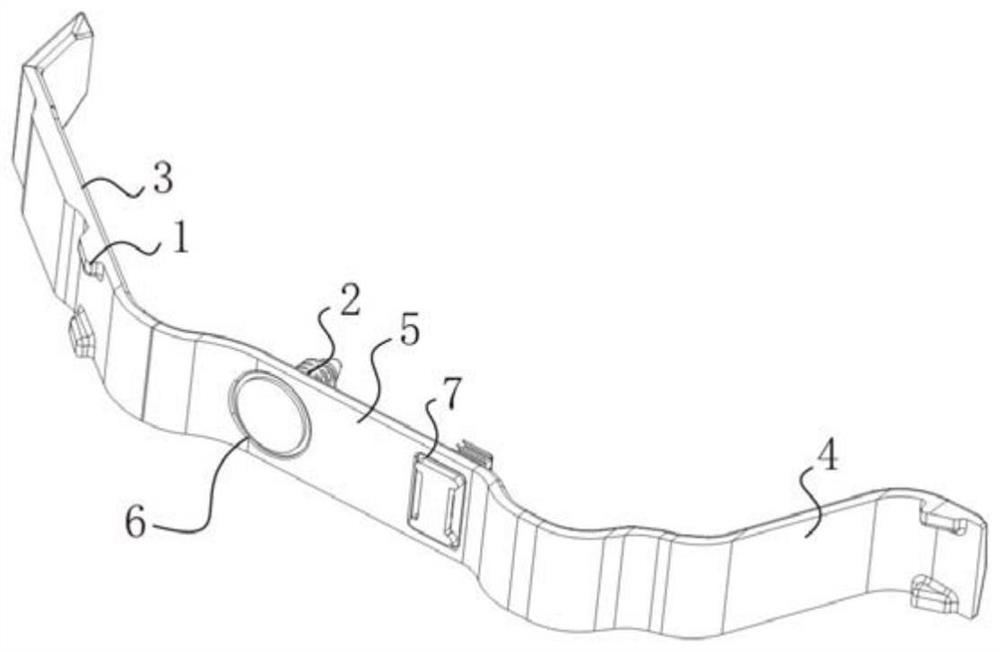

[0011] As shown in the figure, the present invention provides a bypass seal supporting rubber block, which is characterized in that it includes a rubber block structure, a positioning column 1 and a fixing buckle, and the rubber block structure includes a fixed skeleton 3 and The expansion rubber block 4 on the surface of 3, the fixed frame 3 is bent inward on both sides to form a U-shaped long strip, and the middle part of the fixed frame 3 is provided with a connecting part 5, and the positioning column 1 is integrated with the fixed frame 3 Shaped and located on the edge of the fixed frame 3 , the surface of the connecting portion 5 is provided with a fixing hole 6 , and the fixing buckle 2 is matched with the fixing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com