Square board drilling equipment for wood factory

A drilling equipment, wood factory technology, applied in the direction of fixed drilling machines, etc., can solve the problems of complicated operation, inability to control the drilling depth by itself, and inability to realize automatic material pushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

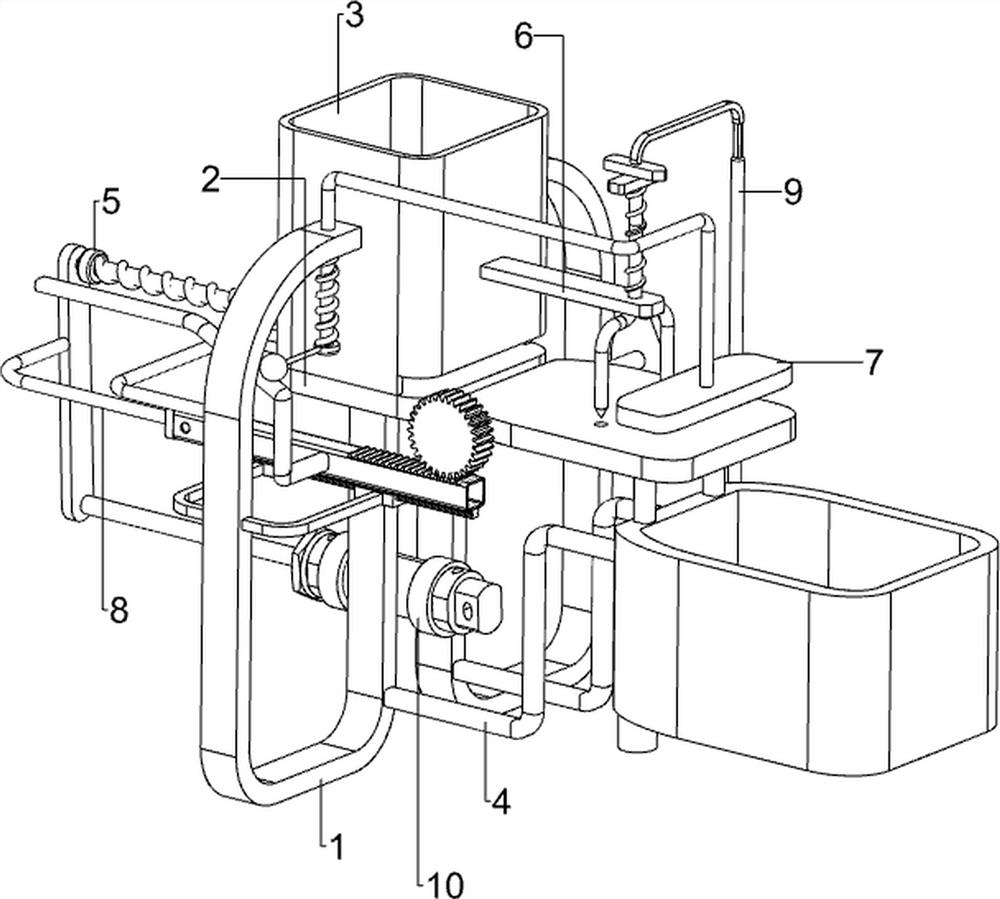

[0055] A kind of equipment for drilling holes in square wooden boards in a wood factory, such as figure 1 As shown, the first support frame 1, the first support plate 2, the discharge frame 3, the second support frame 4, the pushing mechanism 5 and the drilling mechanism 6 are included, and the second support frame 1 is connected between the two first support frames 1. A support plate 2, a discharge frame 3 is connected between the upper parts of the two first support frames 1, the discharge frame 3 is connected with the first support plate 2, and a second support frame is connected between the lower parts of the two first support frames 1 4. The upper part of the rear wall of the first supporting frame 1 on the left is provided with a pushing mechanism 5, and the middle part of the front wall of the discharging frame 3 is provided with a drilling mechanism 6.

[0056] When people want to drill holes in planks, they can use the square plank drilling equipment used in the wood ...

Embodiment 2

[0058] On the basis of Example 1, such as figure 2 and image 3 As shown, the pushing mechanism 5 includes a third support frame 51, a pusher 52 and a first spring 53, and the upper part of the rear wall of the first support frame 1 on the left side is provided with a third support frame 51, and on the third support frame 51 The sliding type is provided with a pusher 52, and a first spring 53 is wound around the pusher 52, and the two ends of the first spring 53 are respectively connected with the third supporting frame 51 and the pusher 52.

[0059]When a plank at the bottom fell on the first supporting board 2, the user pushed the pusher 52 forward, so that the pusher 52 moved forward, the first spring 53 was compressed, and the pusher 52 and the first The plank on the support plate 2 contacts, and the pusher 52 pushes the plank forward to realize the effect of pushing the plank. After the pushing is completed, the pusher 52 is released, and the first spring 53 resets, the...

Embodiment 3

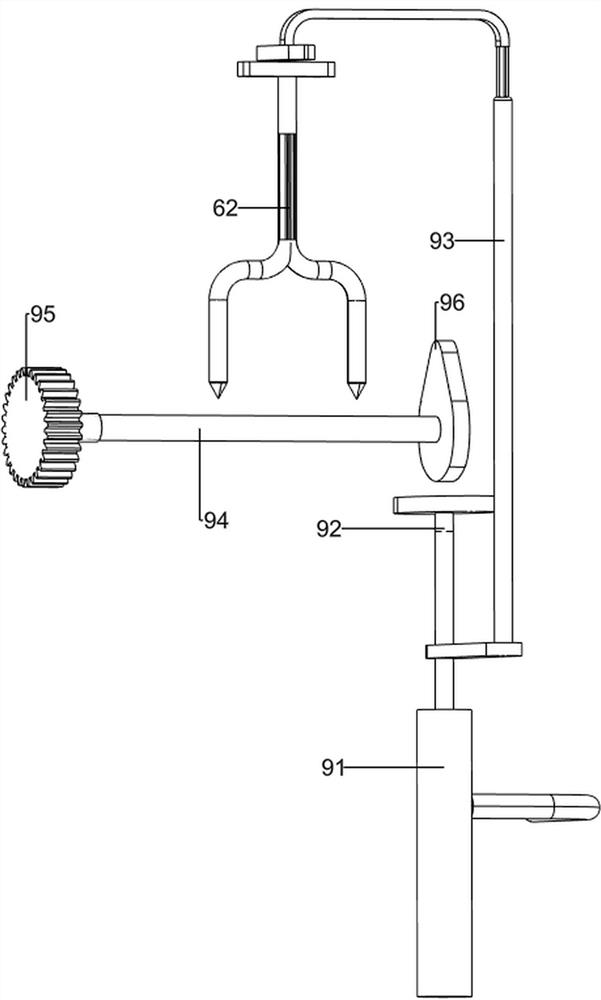

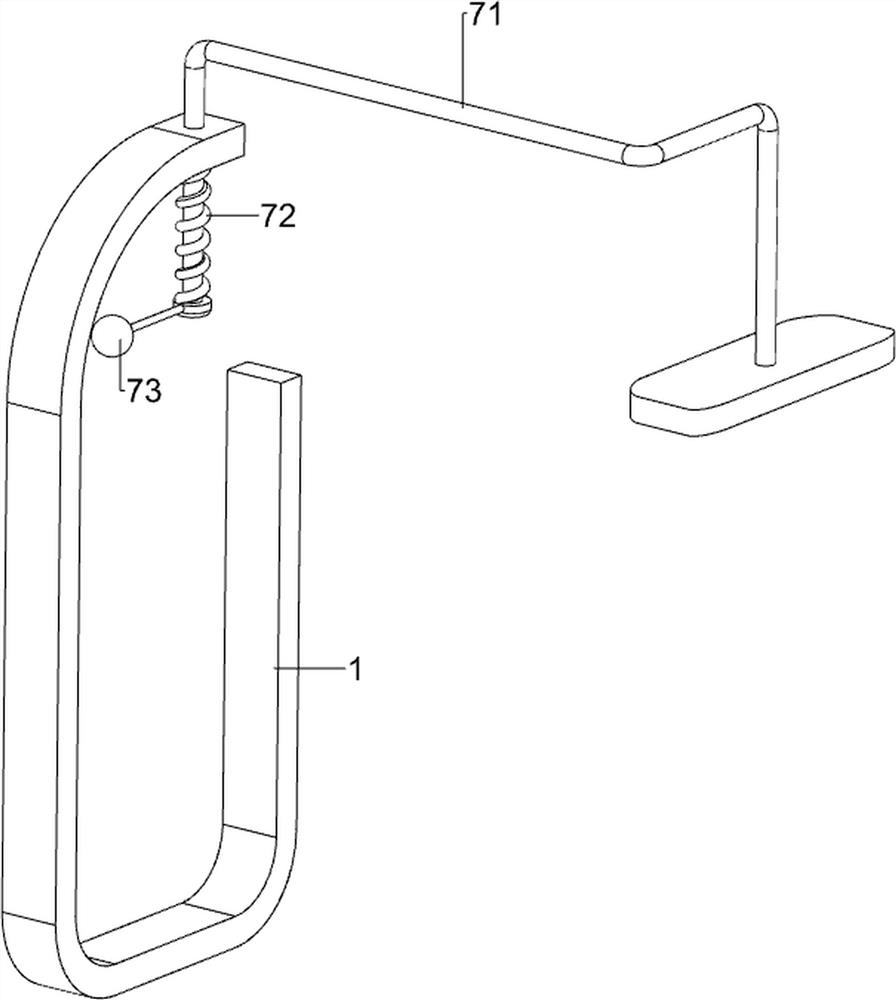

[0063] On the basis of Example 2, such as Figure 4-Figure 7 As shown, it also includes a hold-down mechanism 7, the top of the first support frame 1 on the left side is provided with a hold-down mechanism 7, and the hold-down mechanism 7 includes a presser 71, a third spring 72 and a first club 73, the left side The upper part of the first support frame 1 on the side is slidingly provided with a presser 71, and the bottom end of the rear side of the presser 71 is provided with a first club 73, and the presser 71 is wound with a third spring 72, and the third spring 72 has two The ends are respectively connected with the presser 71 and the first club 73.

[0064] The user pushes the first club 73 upwards, the third spring 72 is compressed, the first club 73 drives the presser 71 to move upward, and when the plank is pushed onto the second support frame 4, the first club 73 is released , the third spring 72 resets, thereby driving the first club 73 and the presser 71 to move d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com