Frozen storage method for minced fish

A technology of surimi and fish sticks, which is applied in the field of aquatic product processing, can solve the problems of easy loss of protein and lower quality of surimi finished products, and achieve the effects of improving the taste and nutritional value, ensuring quality, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] Embodiment two comprises the following steps:

[0051] The first step, descaling and bloodletting: remove the scales from the fresh fish, make an incision under the fins, and then bleed in clean water;

[0052] The second step, low-temperature deacidification: Put the fresh fish after bloodletting into clean water, slowly reduce the temperature of the clean water to 2°C and soak for 5 minutes through air-conditioning;

[0053] The third step, pretreatment: the soaked fish is deboned, deboned, peeled, and cut into strips to form strips of fish strips;

[0054] The fourth step, low-temperature salt rinsing: rinse the sliced fish sticks in 0.2% salt water at 2°C;

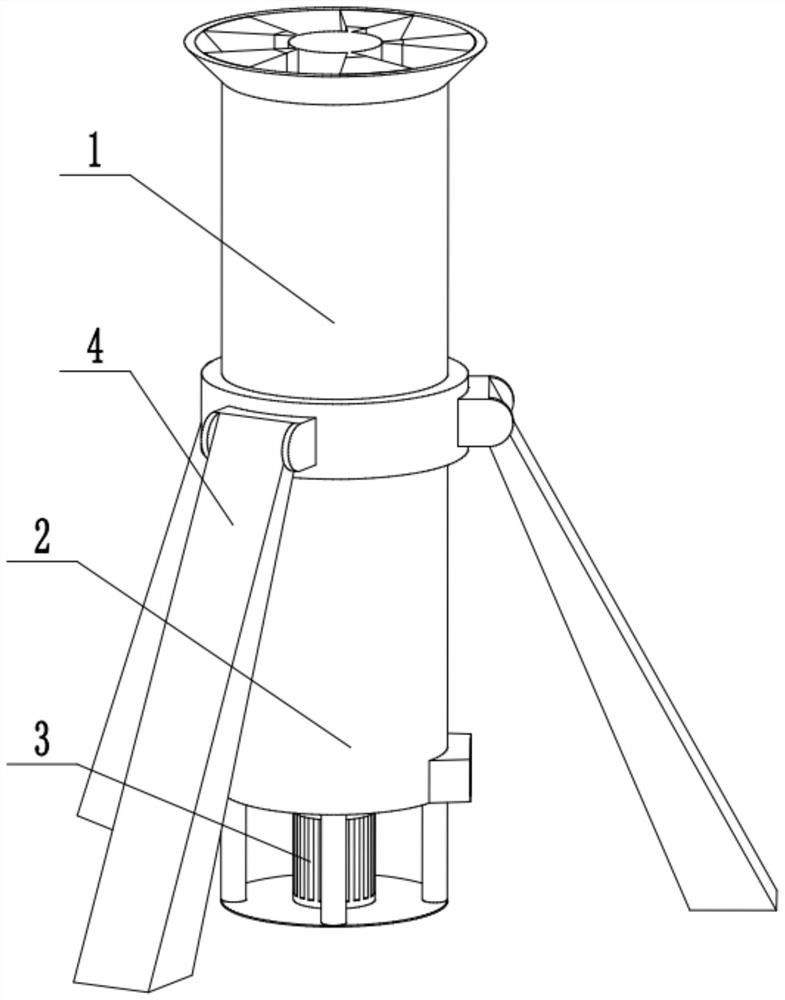

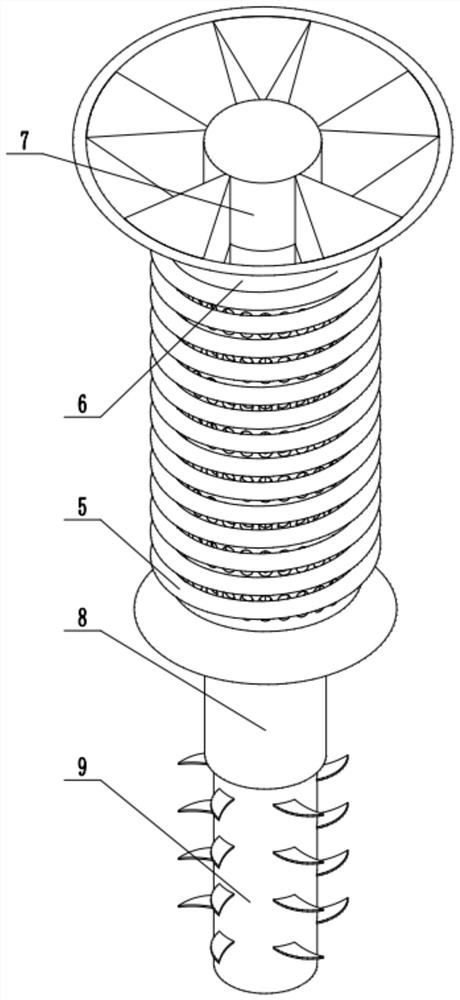

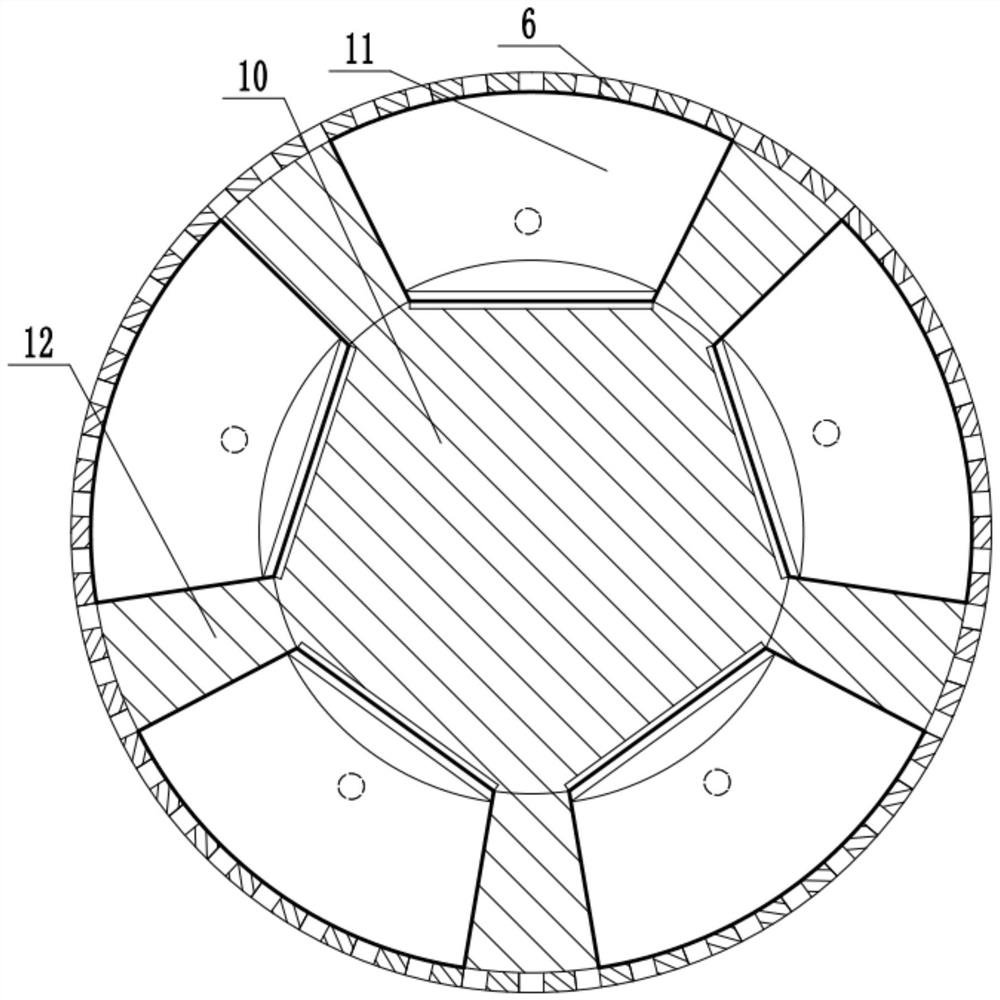

[0055] The fifth step, low-temperature dehydration: perform low-temperature and low-speed dehydration for 15 minutes in the low-temperature dehydration equipment for fish sticks after rinsing; in order to realize the above method, the present invention also provides a low-temperature dehydration and chopping ...

Embodiment 3

[0064] Embodiment three comprises the following steps:

[0065] The first step, descaling and bloodletting: remove the scales from the fresh fish, make an incision under the fins, and then bleed in clean water;

[0066] The second step, low-temperature deacidification: Put the fresh fish after bloodletting into clean water, and slowly reduce the temperature of the clean water to 1°C through air-conditioning and soak for 5.5 minutes;

[0067] The third step, pretreatment: the soaked fish is deboned, deboned, peeled, and cut into strips to form strips of fish strips;

[0068] The fourth step, low-temperature salt rinsing: rinse the sliced fish sticks in 0.25% salt water at 1°C;

[0069] The fifth step, low-temperature dehydration: the fish sticks after rinsing are dehydrated at low temperature and low speed for 20 minutes in the low-temperature dehydration equipment; in order to realize the above method, the present invention also provides a low-temperature dehydration and ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com