Cost-reducing and efficiency-increasing greenhouse pepper planting technology

A planting technology, pepper technology, applied in seed coating/seed dressing, fruit tree cultivation, etc., can solve the problems of large labor input, avoid competition, reduce the possibility of seed damage, and reduce labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

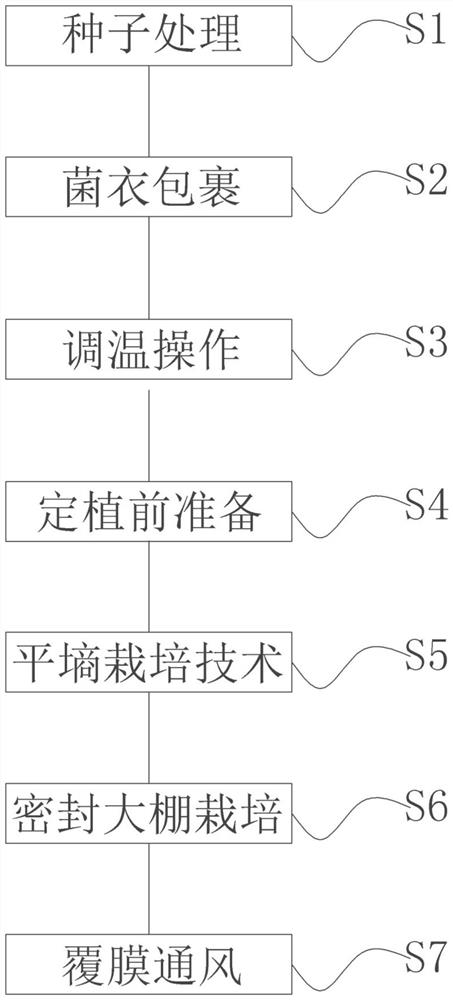

[0025] The embodiment is basically as attached figure 1 Shown: a kind of greenhouse capsicum planting technique of saving cost and increasing efficiency comprises the following steps:

[0026] S1, seed treatment, the seeds are disinfected and soaked to accelerate germination before sowing;

[0027] S2, bacteria coating, use carbendazim, chlorothalonil or Zinc to sterilize the plugs, and then sprinkle water on the plugs to prevent the plugs from being fully watered. Cover the seeds with the sterilized substrate, put the plug into the greenhouse, use the plug to grow seedlings, first coat the seeds, and then fill the holes in the plug with the substrate. The coating material includes gum arabic, and the substrate is pasted The place next to the coating is peat, perlite and straw fermented product in turn, and then the plug tray is buried in the soil and covered with plastic film and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com