Tooth yoke separation type permanent magnet synchronous motor stator structure

A permanent magnet synchronous motor and stator structure technology, applied in the field of electric motors, can solve problems such as shortening the service life of the motor, vibration and noise of the motor, and increased deflection of the motor, and achieve the effect of solving winding problems, high precision, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. The described embodiments are only illustrations and explanations of the present invention, and do not constitute the only limitation of the present invention.

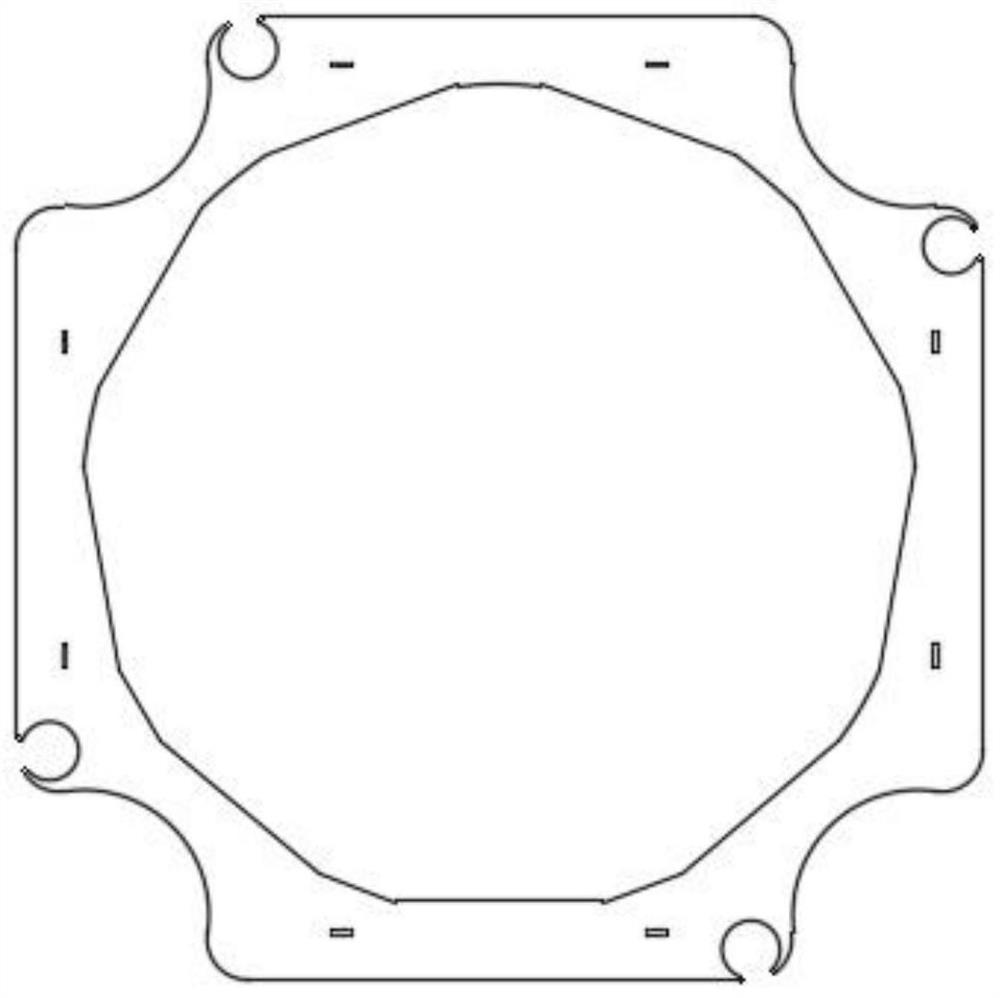

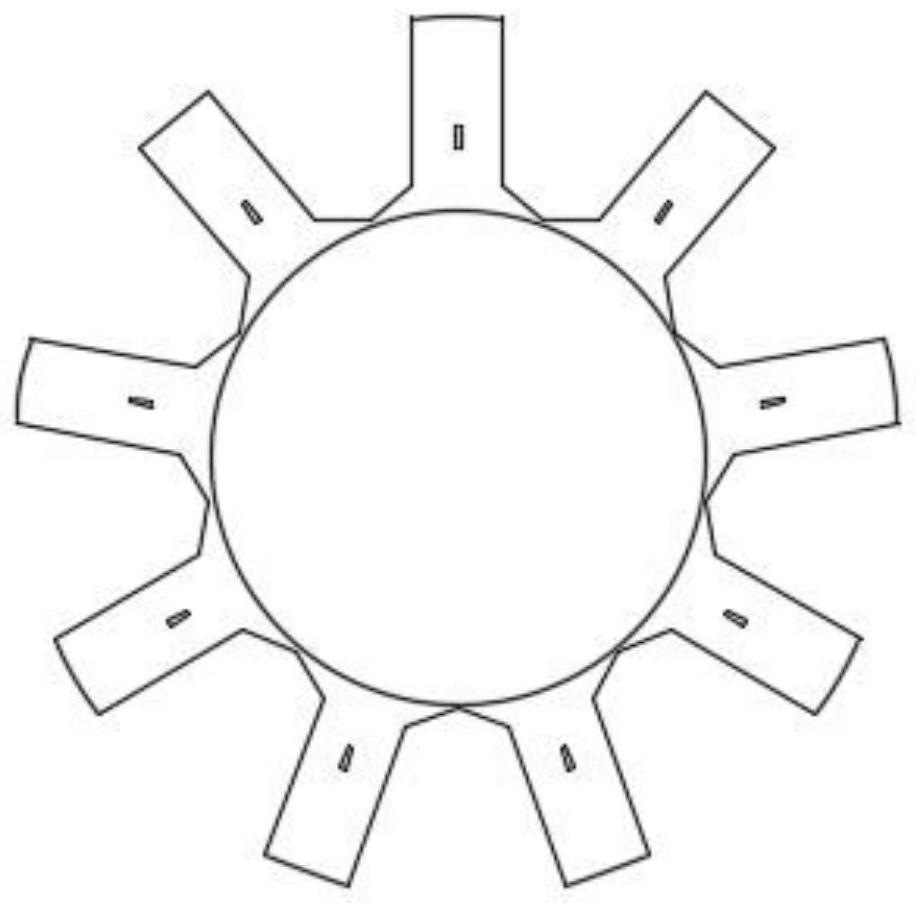

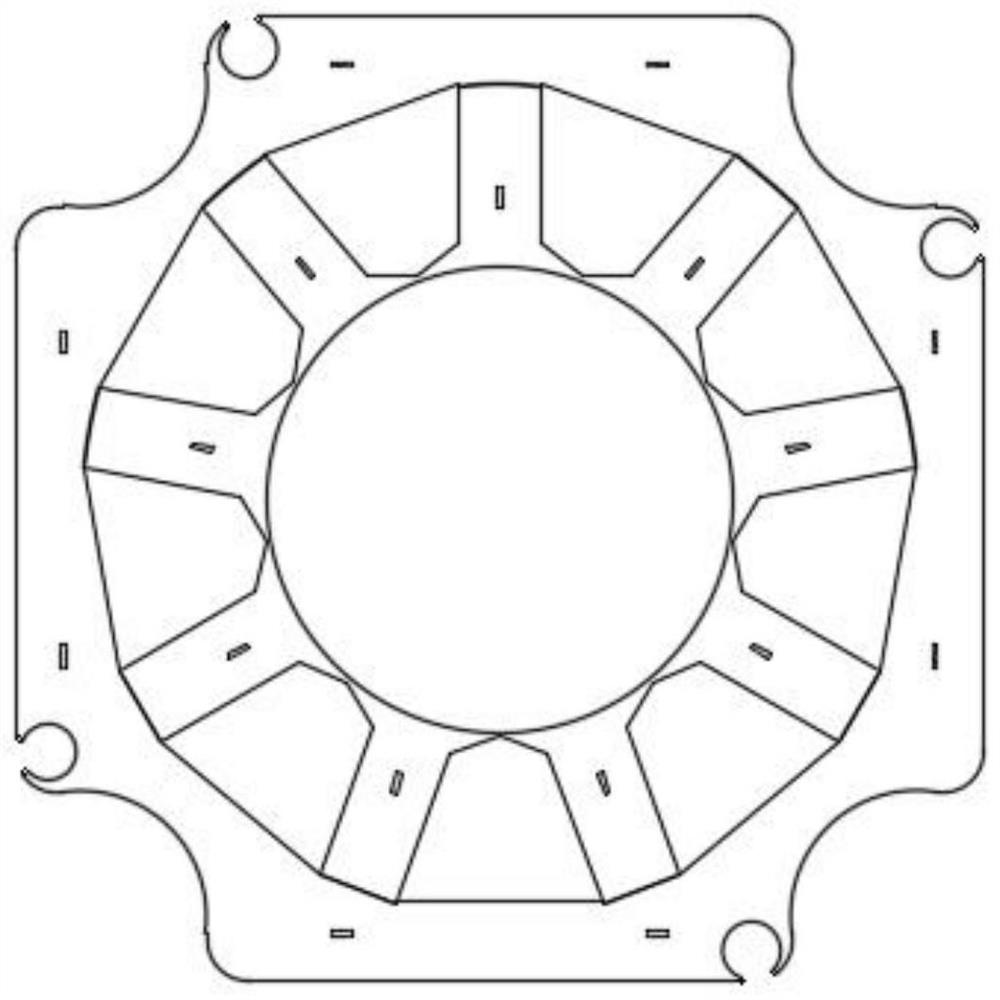

[0020] Such as Figure 1-Figure 6 As shown, the present invention includes a stator yoke and a stator tooth. The stator yoke and the stator tooth are punched and laminated by cold-rolled silicon steel sheets. The outside of the stator tooth is provided with a plurality of protrusions and surrounds the stator. For the stator teeth arranged in the tooth section, the inner hole profile of the stator yoke is formed by splicing multiple segments of arc lines, and the arc lines are connected by line segments, and each segment of arc line corresponds to a stator tooth on the stator tooth section. Preferably, stator slots are formed between the stator teeth, and insulating paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com