Silent negative pressure circulation oxygen generator

An oxygen generator and negative pressure technology, applied in the field of oxygen generators, can solve the problems of complicated molecular sieve replacement, poor air circulation effect, low air replacement rate, etc., to avoid bad experience and low-frequency noise damage, convenient maintenance, and simplified disassembly. The effect of the installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

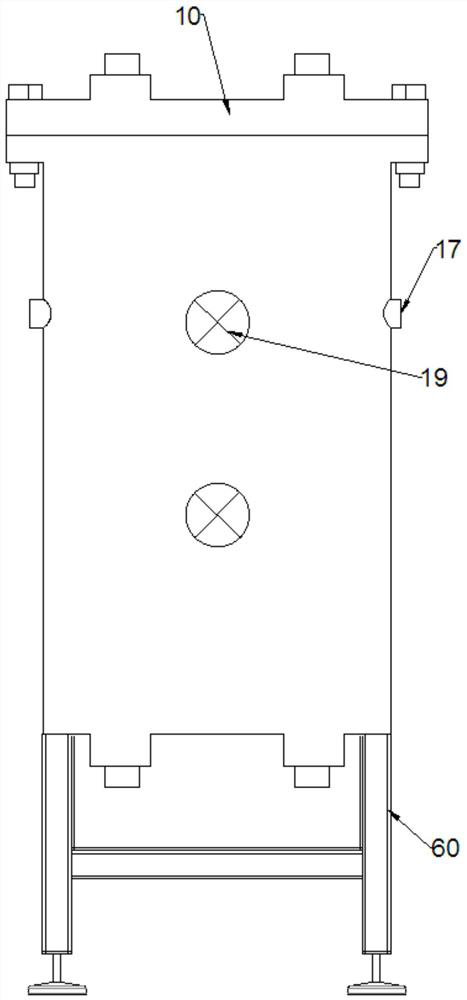

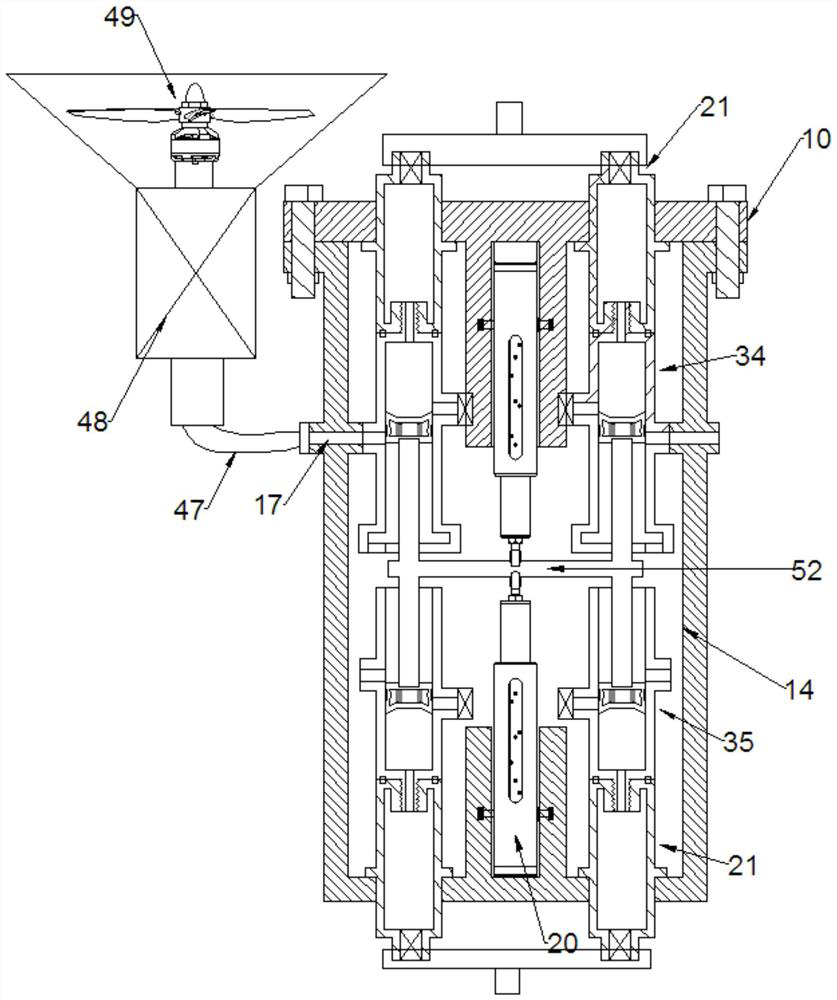

[0031] A silent negative pressure circulation oxygen generator described in conjunction with accompanying drawings 1-6 includes an end cover 10 and a housing 14. The end cover 10 is a round cake-shaped flange, and the left and right symmetrical arrangements are made on the end cover 10. There are two molecular sieve positioning holes 12 penetrating up and down, the inner wall of the lower end of the end cover 10 is fixed with a positioning flange 11, the upper end of the housing 14 is provided with an opening, and the inside of the housing 14 is provided with a cavity 18. The middle part of the housing 14 is symmetrically provided with two air inlet joints 17 penetrating left and right, and the lower end of the housing 14 is symmetrically provided with two molecular sieve holes 15 penetrating up and down. Clamp block 16, the middle part of the housing 14 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com