Powder processing device for preventing dust from flying by adopting centrifugal method

A processing device and a technology for preventing dust, applied in the directions of mixing methods, transportation and packaging, chemical instruments and methods, etc., can solve the problems of insufficient mixing of medicinal powder and distilled water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

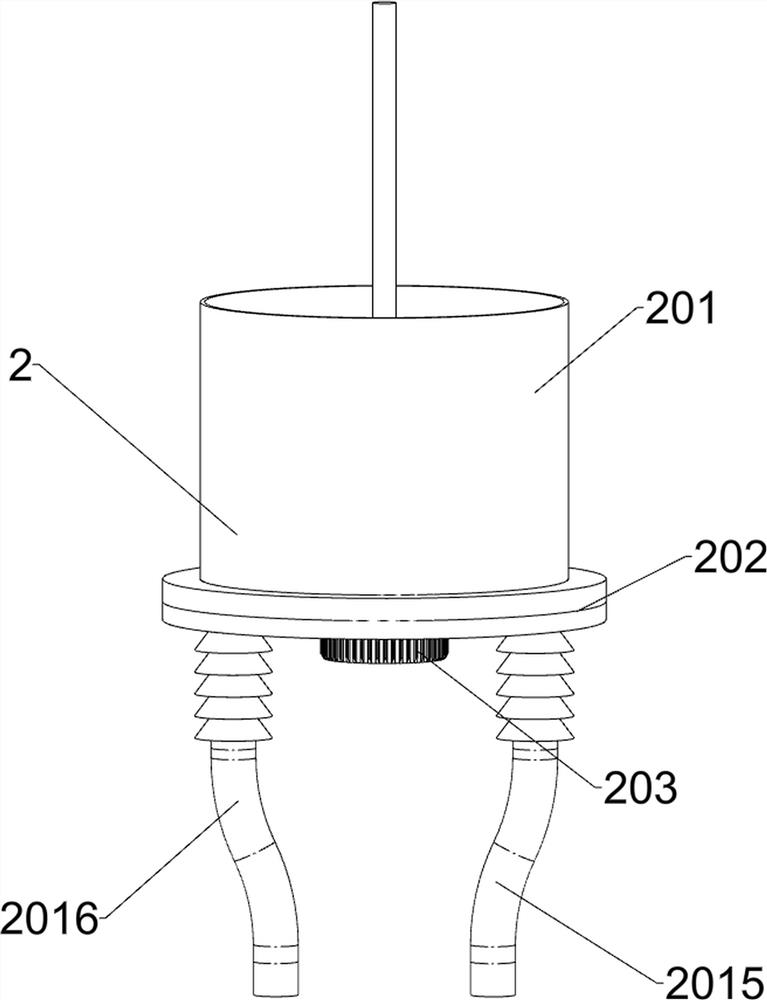

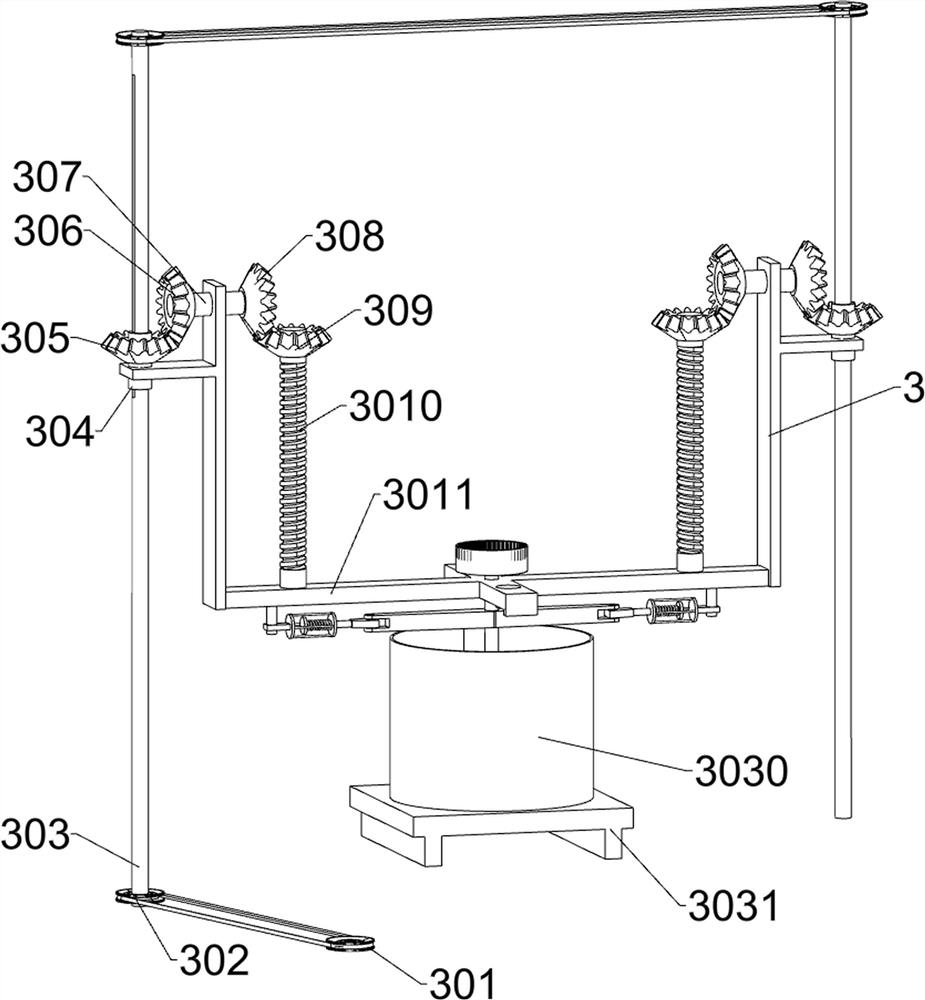

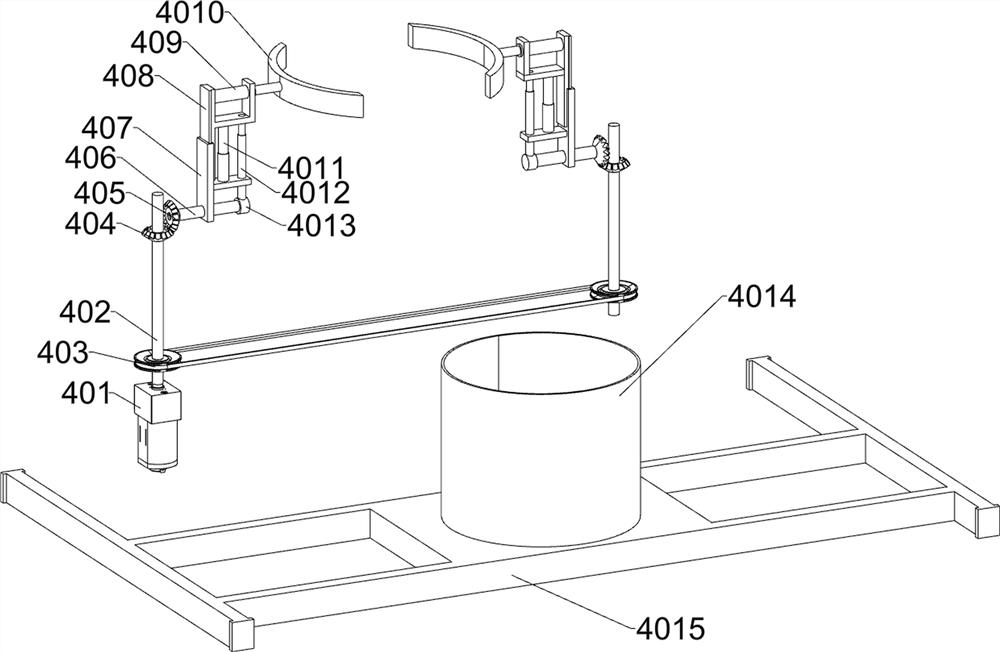

[0028] A kind of anti-dust powder processing device using centrifugal method, such as Figure 1-8 As shown, it includes a bottom frame 1, a dry powder mixing unit 2, an eccentric stirring unit 3, a turning unit 4 and a control panel 5; the bottom frame 1 is connected with the dry powder mixing unit 2; the bottom frame 1 is connected with the eccentric stirring unit 3 The bottom frame 1 is connected with the turning unit 4; the bottom frame 1 is connected with the control panel 5; the dry powder mixing unit 2 is connected with the eccentric stirring unit 3;

[0029] Working process: when in use, first place the centrifugal dust-proof powder processing device at the position to be used, place the bottom frame 1 on a stable position, then connect the external power supply, and start the device through the control panel 5; first put the powder Put it into the dry powder mixing unit 2, so that the colors of the powders of different colors are evenly mixed, then slowly pass the powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com