Air purification system for printing workshop

An air purification system and technology for printing workshops, applied in the field of air purification systems in printing workshops, can solve the problems that it is difficult to reach a thousand-level dust-free workshop, the bag filter is large in size, and the dust removal efficiency fluctuates greatly, and it can achieve convenient replacement of filter elements, The effect of avoiding facility damage and reducing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

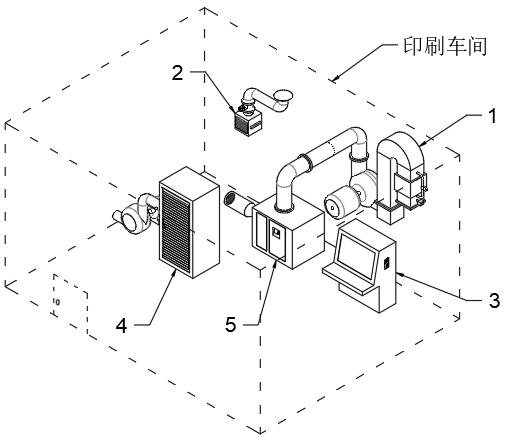

[0032] Such as figure 1 As shown, an air purification system in a printing workshop includes an air intake device 1 and an exhaust device 2. The inlet of the air intake device 1 is provided with a dust removal device for filtering dust and other particles in the air, and the outlet of the air intake device 1 There is an air compressor 5, which is used to compress the gas discharged from the air intake device 1 and release it to the inside of the workshop to increase the air pressure inside the workshop. It also includes a console 3, an internal gas circulation device 4, and a gas The internal circulation device 4 is mainly used to remove dust in the air inside the printing workshop, and remove other suspended matter. The console 3 is a computer, which can display the air intake device 1, the exhaust device 2, the air compressor 5, and the gas internal circulation device. 4 operating status, and control its operating parameters.

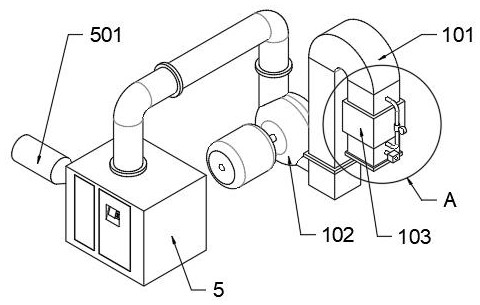

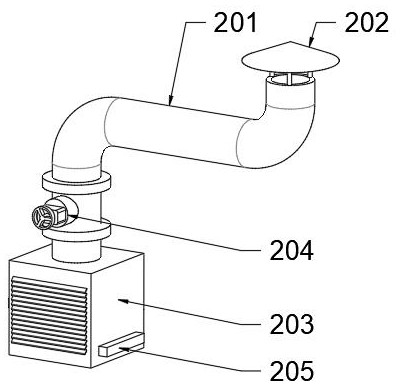

[0033] Such as figure 2 , Figure 6 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com