Impeller structure for double-layer spraying system and cleaning machine applying impeller structure

A spray system and impeller technology, applied in the field of cleaning machines, can solve problems such as affecting the cleaning effect and user experience, residual impurities, and high appearance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

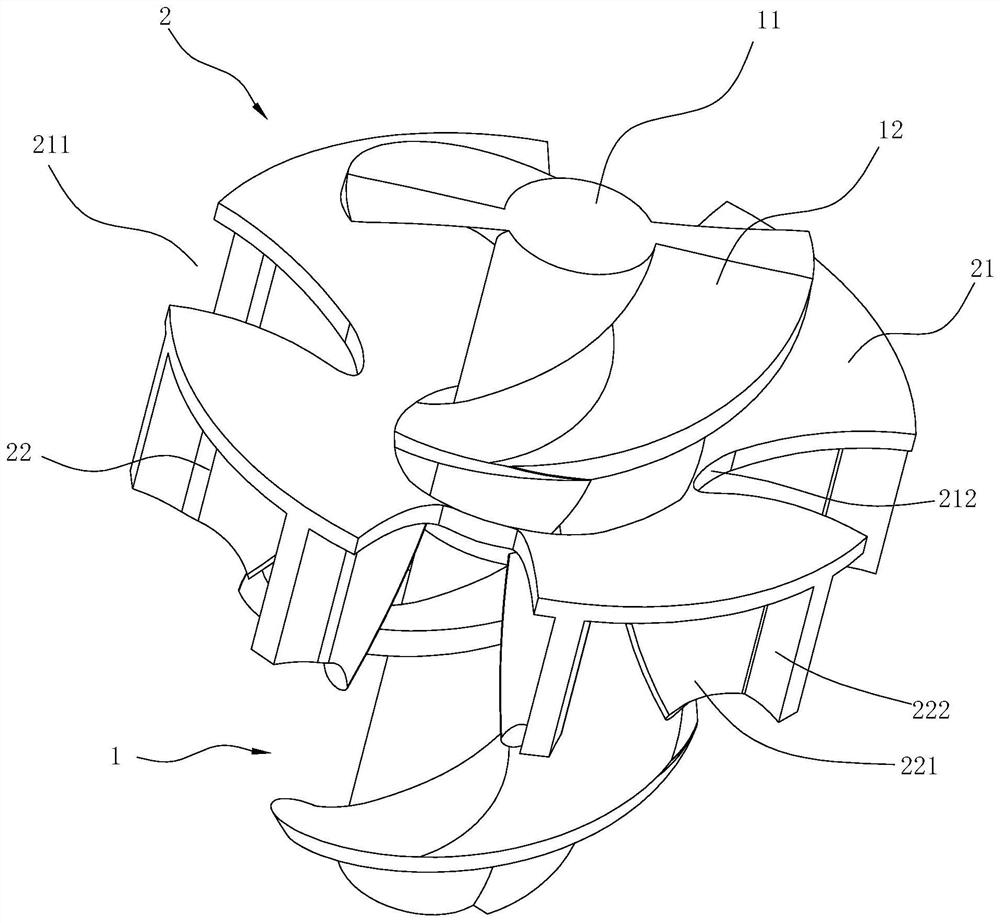

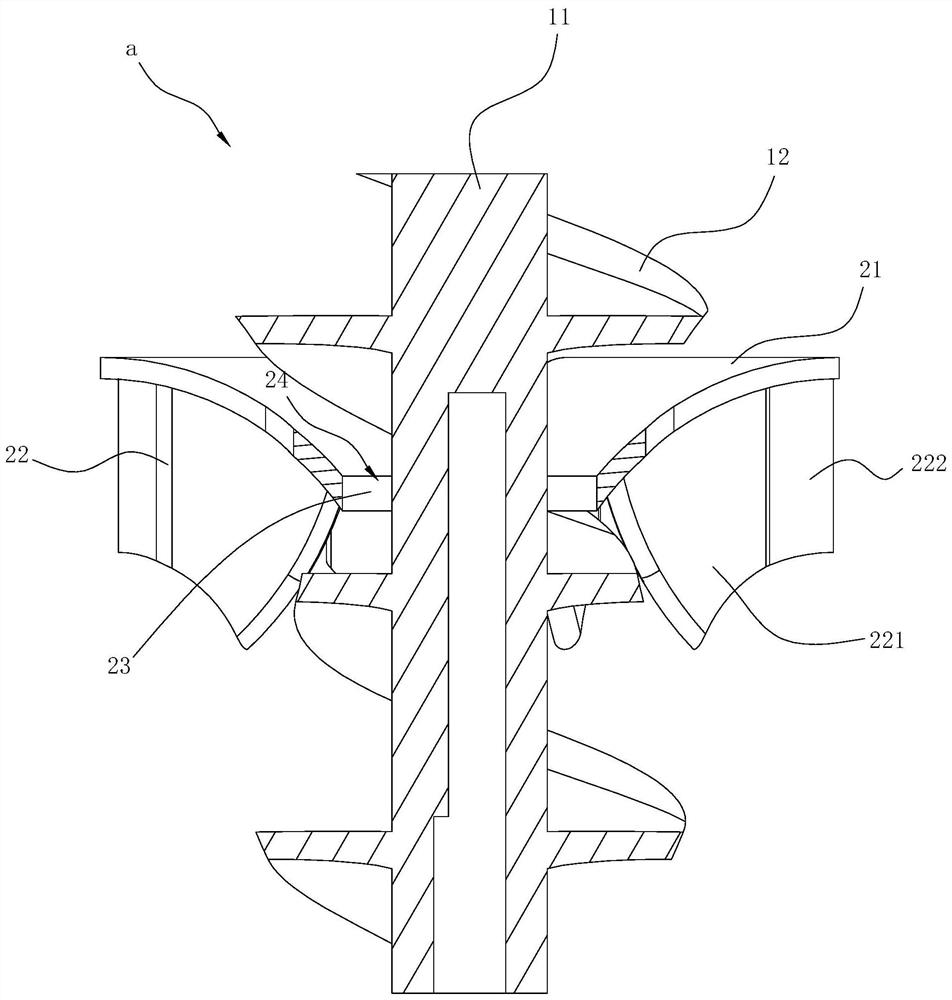

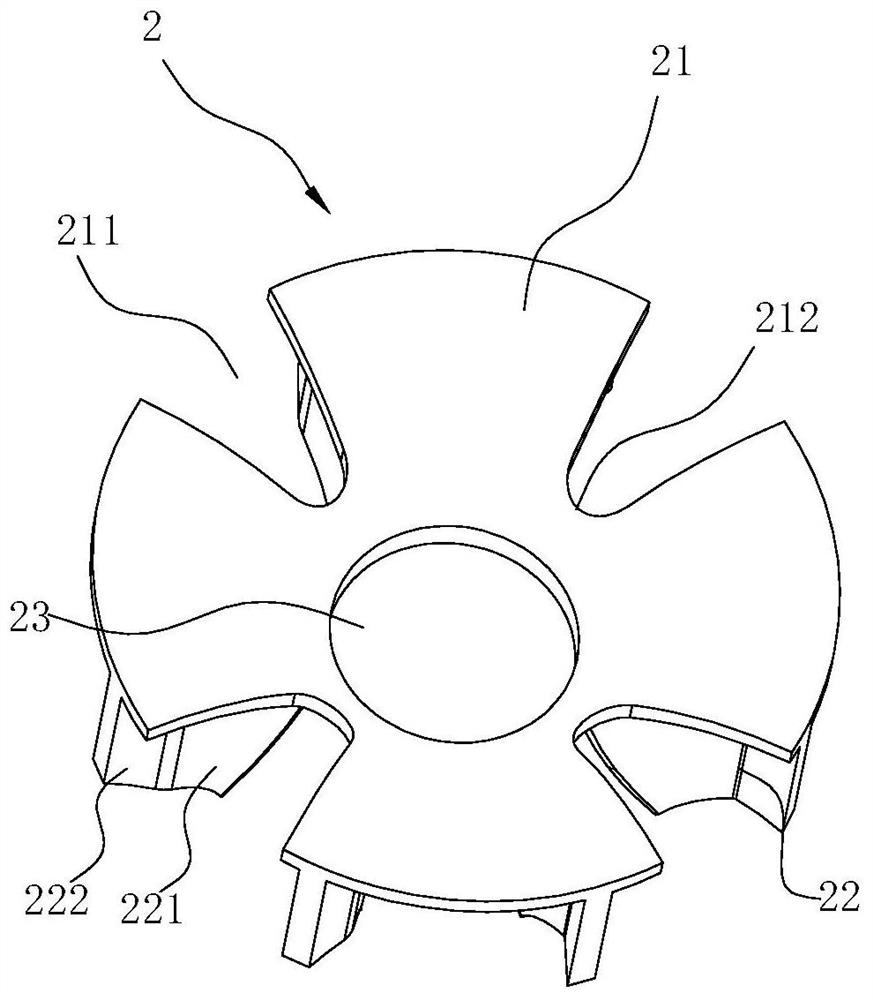

[0023] Such as Figure 1~5 As shown, the impeller structure used in the present embodiment for the double-deck sprinkler system includes a first impeller 1 and a second impeller 2. The first impeller 1 has a shaft 11 located in the center and spirals axially on the outer peripheral wall of the shaft 11. The coiled first blade 12, ie, the first blade 12 is an axial flow blade for drawing water in the axial direction. The second impeller 2 is sleeved on the outer periphery of the first impeller 1 and can rotate synchronously with the first impeller 1. The second impeller 2 has a second blade 22 extending radially along the first impeller 1. The second blade 22 is a centrifugal blade and There are several and are used to disperse the water circumferentially.

[0024] The above-mentioned second impeller 2 also includes an end cover 21 located ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com