Electromagnetic wave lens, electromagnetic wave lens production method and lens antenna

An electromagnetic wave and lens technology, applied in the direction of antennas, electrical components, etc., can solve the problems of single hot-melt material, high cost, heavy installation and use difficulties, etc., and achieve the effect of compact and stable structure, high product consistency, and good electromagnetic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

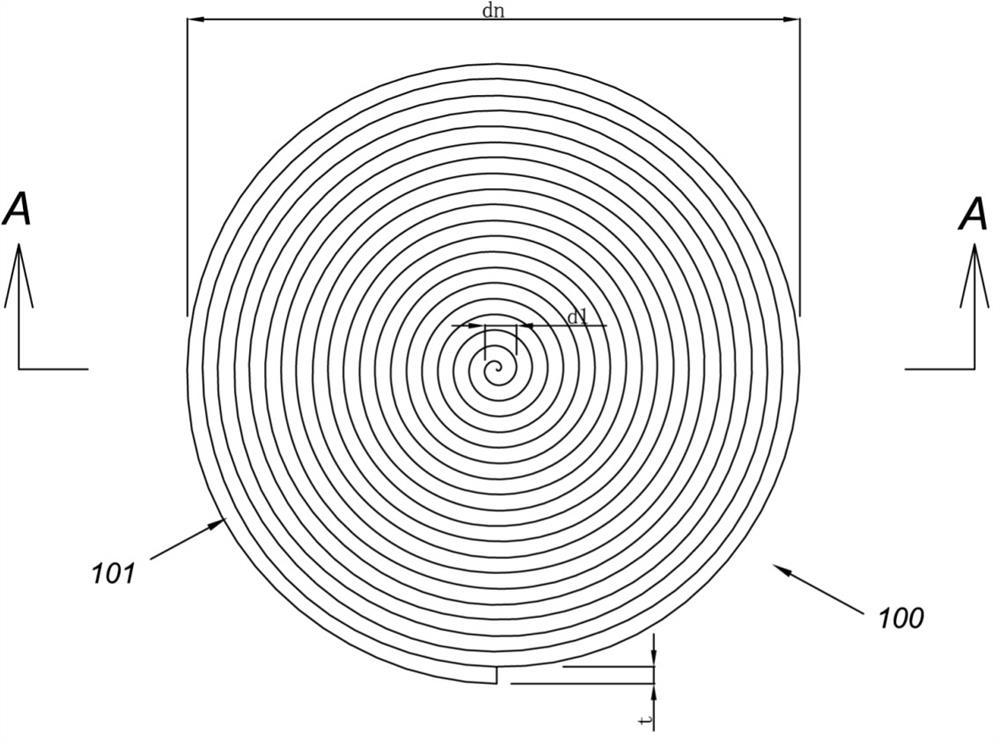

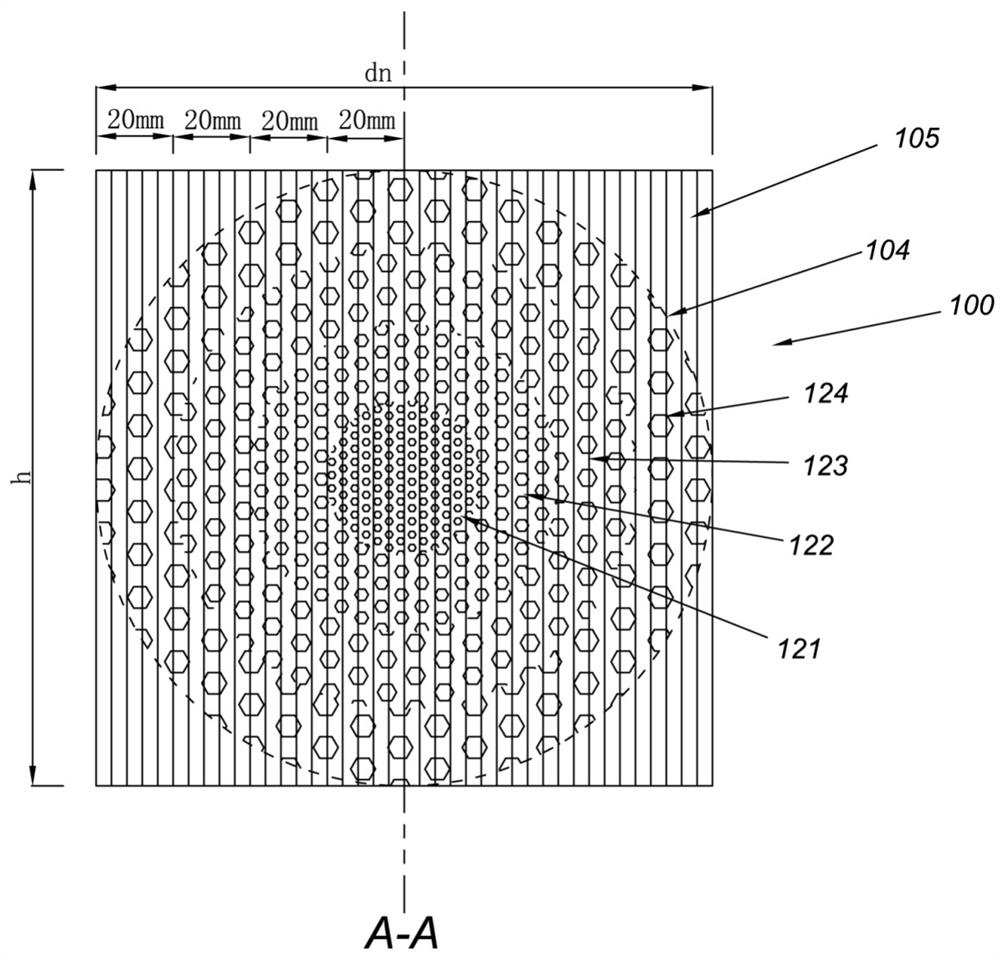

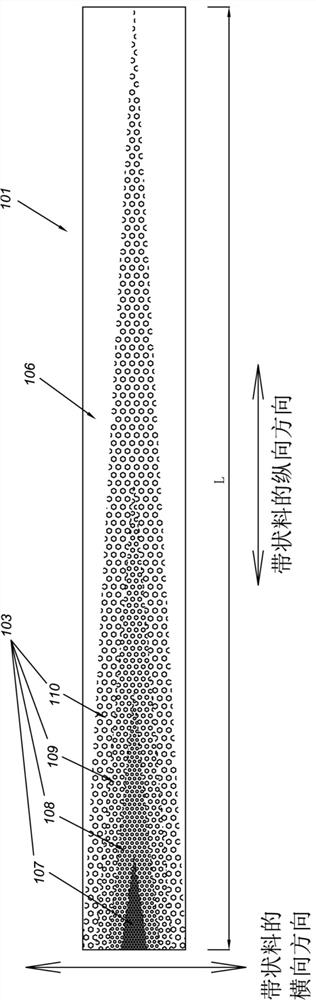

[0098] Present embodiment is the production method of electromagnetic wave lens and electromagnetic wave lens, as figure 1 , figure 2 As shown, the electromagnetic wave lens is a cylindrical rolled body 100 rolled from a strip material 101, as image 3 As shown, since the medium material is distributed on the surface of the strip material 101, and the medium material is distributed in a region of a specific shape, such a region is called the medium distribution area 103, and the strip material 101 is made into a rolled body After 100, the dielectric material will be distributed in an artificially predetermined spherical range inside the rolling body 100, and the spherical range where the dielectric material is distributed is the lens body 104 of the electromagnetic wave lens of this embodiment. The parts other than the lens body 104 of the rolled body 100 are referred to as non-lens parts 105 . The non-lens portion 105 is formed by the non-dielectric distribution area 106 o...

Embodiment 2

[0116] Such as Figure 7 As shown, this embodiment is an electromagnetic wave lens, and the rolled body 200 adopts the rolling method and structure of Embodiment 1, but two spherical lens bodies 201 of the same size are formed inside the rolled body 200, and the two lenses The bodies 201 are located at the two ends of the cylinder respectively. In the two lens bodies 201, all the dielectric constants are getting lower and lower from the inside to the outside. The two lens bodies 201 are arranged along the central axis direction of the rolled body 200 .

Embodiment 3

[0118] Such as Figure 8 , Figure 9 As shown, this embodiment is an electromagnetic wave lens, and the rolling body 300 is a quadrangular prism, and a spherical lens body 301 is formed inside the rolling body 300 . In the lens body 301 , the dielectric constant becomes lower and lower in all directions from the inside to the outside, and the central axis of the lens body 301 coincides with the central axis of the rolled body 300 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com