An oil level calibration device and method

The technology of a calibration device and calibration method, which is applied in the field of oil level calibration, can solve the problems of large oil level calibration error, equipment damage, high electric shock, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

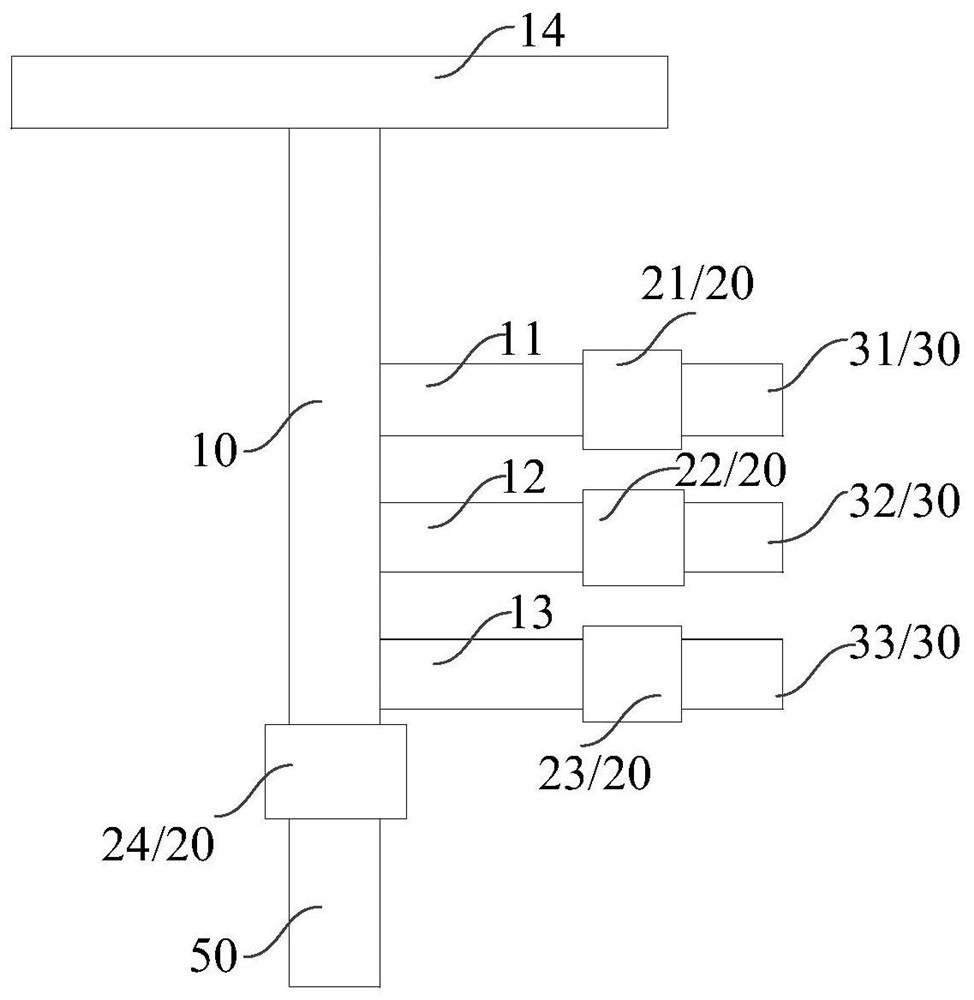

[0031] figure 1 It is a schematic structural diagram of an oil level calibration device provided in Embodiment 1 of the present invention, figure 2 This is a structural block diagram of a part of the structure of an oil level verification device provided in Embodiment 1 of the present invention. This embodiment can be applied to verifying the oil level of a transformer, etc. figure 1 and figure 2 , the oil level calibration device includes: a main body 10 , a plurality of valves 20 , a plurality of pressure sensors 30 corresponding to the plurality of valves one-to-one, and a control module 40 .

[0032] The top of the main body 10 is connected to the oil conservator through the oil drain pipe 110 of the oil conservator 100; each valve 20 is installed at different heights of the main body 10; The position height of 10 is the same as the position height of the corresponding valve 20, the distance between each pressure sensor 30 is the same, and the pressure sensor 30 is use...

Embodiment 2

[0049] Figure 4 This is a flowchart of an oil level verification method provided in Embodiment 2 of the present invention. The oil level verification method is executed by the control module in the oil level verification device according to any embodiment of the present invention, and specifically includes the following steps:

[0050] S110. Receive the pressure of the oil in the oil storage tank collected by the pressure sensor.

[0051] Wherein, the pressure sensor in the oil level calibration device includes a first pressure sensor, a second pressure sensor and a third pressure sensor. The position of the first pressure sensor on the main body is higher than that of the second pressure sensor, and the second pressure sensor When the position height of the main body is higher than the position height of the third pressure sensor, the pressure of the oil collected by the first pressure sensor is the first pressure P 1 , the pressure of the oil collected by the second pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com