Coaxial staged combustor for low-pollution combustion chamber of gas fuel gas turbine

A technology of gas turbines and gas fuels, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as combustion instability, and achieve the effects of preventing ablation burners, low pollutant emissions, and uniform fuel flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

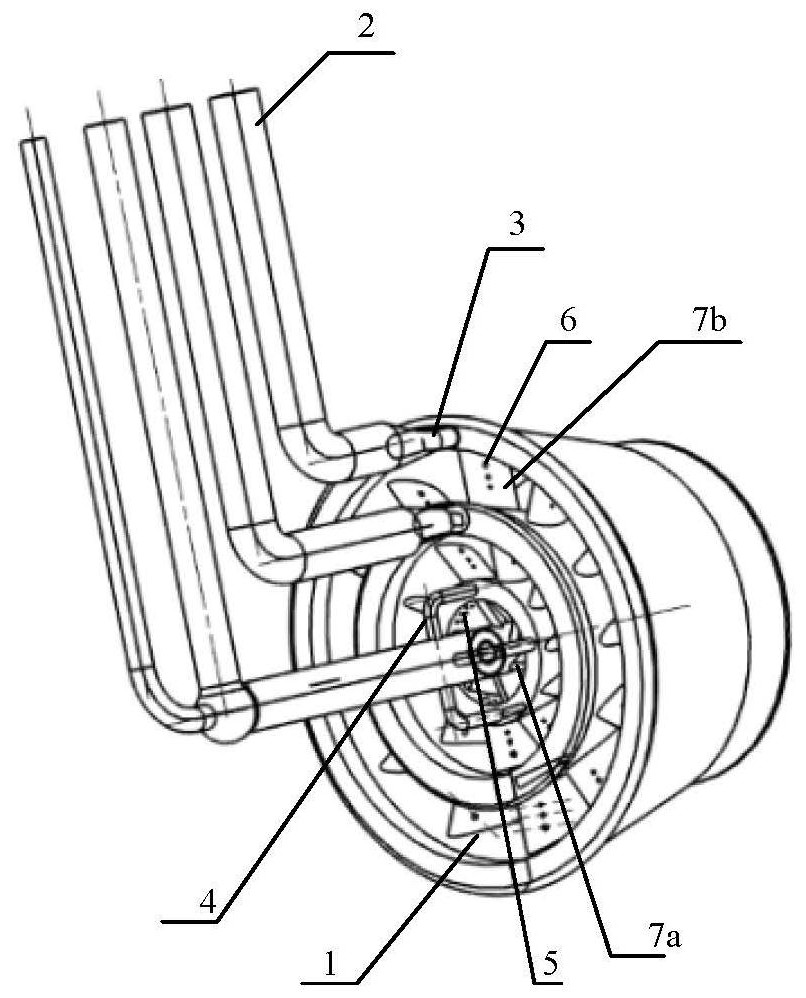

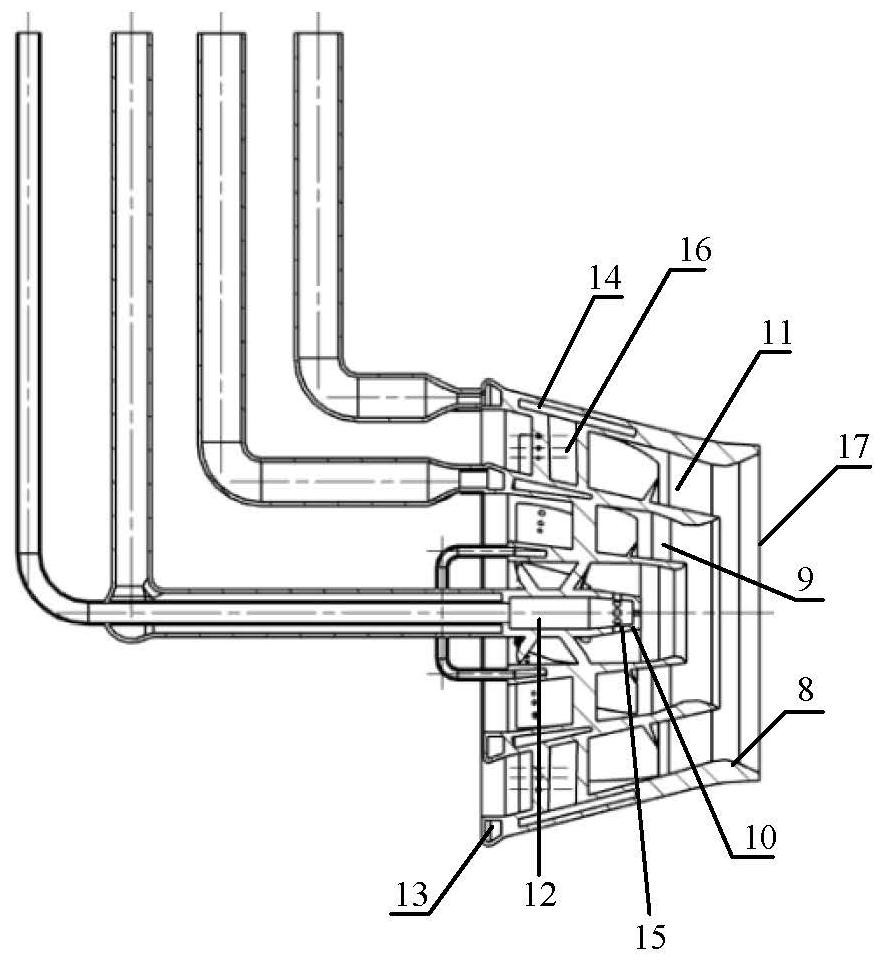

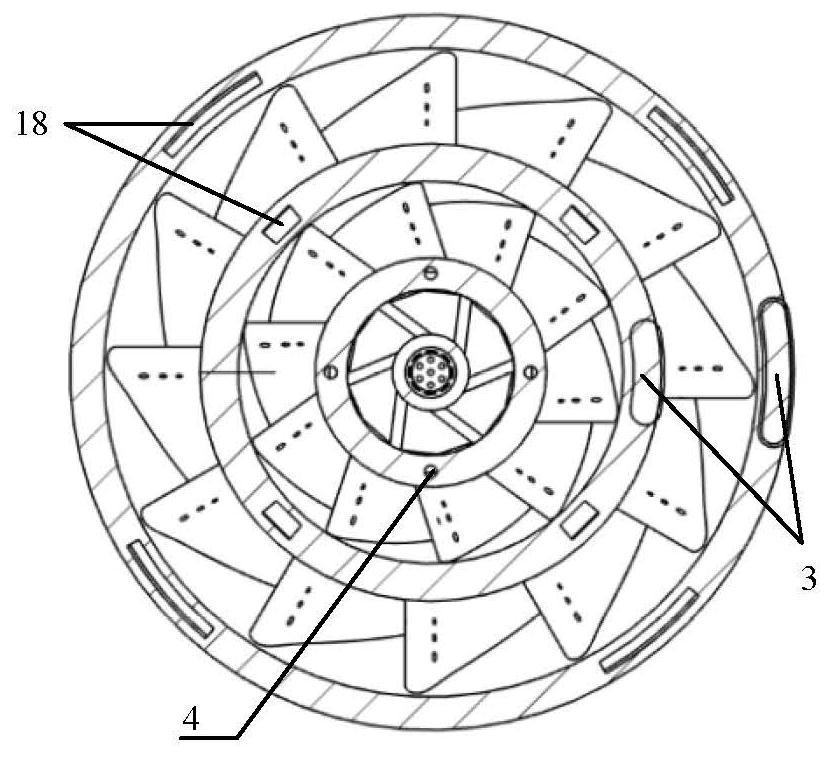

[0030] refer to Figure 1 to Figure 4 , this embodiment is used for the coaxial staged burner of the low-pollution combustion chamber of the gas turbine. The hub fuel ring cavity is set in the outer hub of the swirler, the blade fuel cavity is set in the second and third stage swirl blades, the center blunt body fuel cavity is set in the center blunt body of the swirler; the hub fuel ring cavity is set outside the first stage Four fuel branch circuits, rectified fuel ring chambers are set in front of the outer hubs of the second and third stages to ensure uniform fuel flow in the interblade flow channels of the same stage.

[0031] The swirl vane is located in the tapered swirl channel, the tapered mixing section is located behind the swirl vane in the tapered swirl channel, the first-stage fuel branch is located in front of the first-stage outer hub, and the rectified fuel ring cavity is located in the second In front of the outer hubs of the first and third stages, the hub ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com