Micro-scale premixing staged combustor

A micro-scale, staged combustion technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problems of high NOx emissions, inability to meet the requirements of pollutant emissions and flame stability, and poor flame stability, and achieve pollution. Low emissions, compact structure and low pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

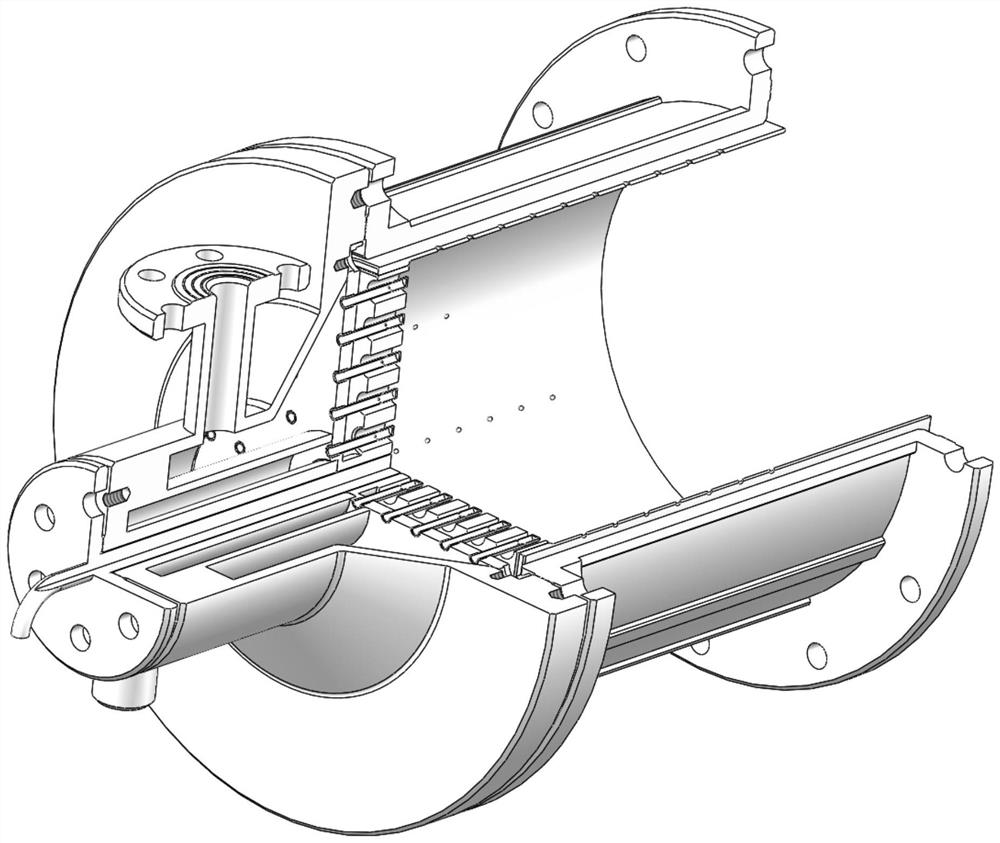

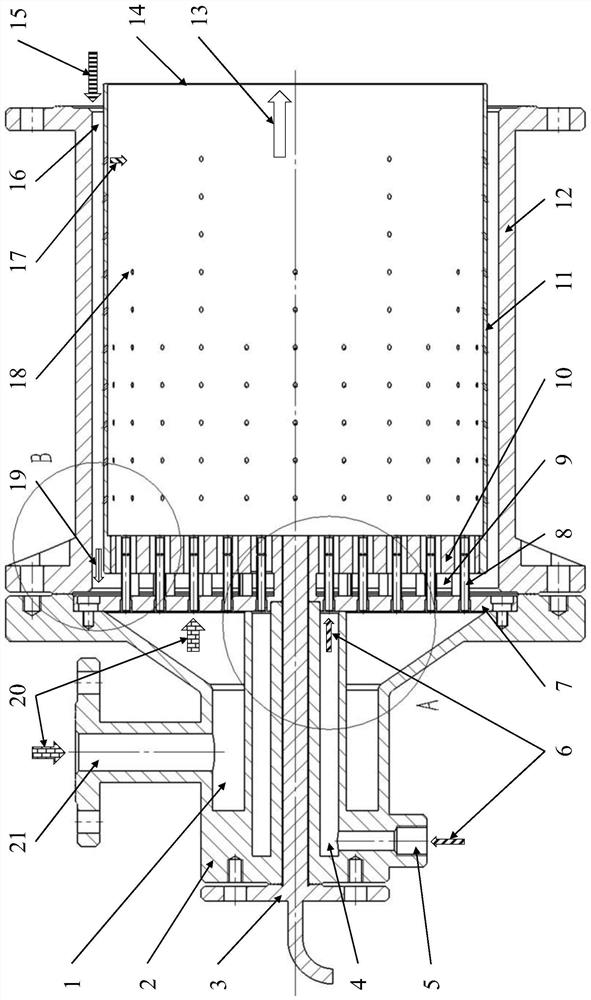

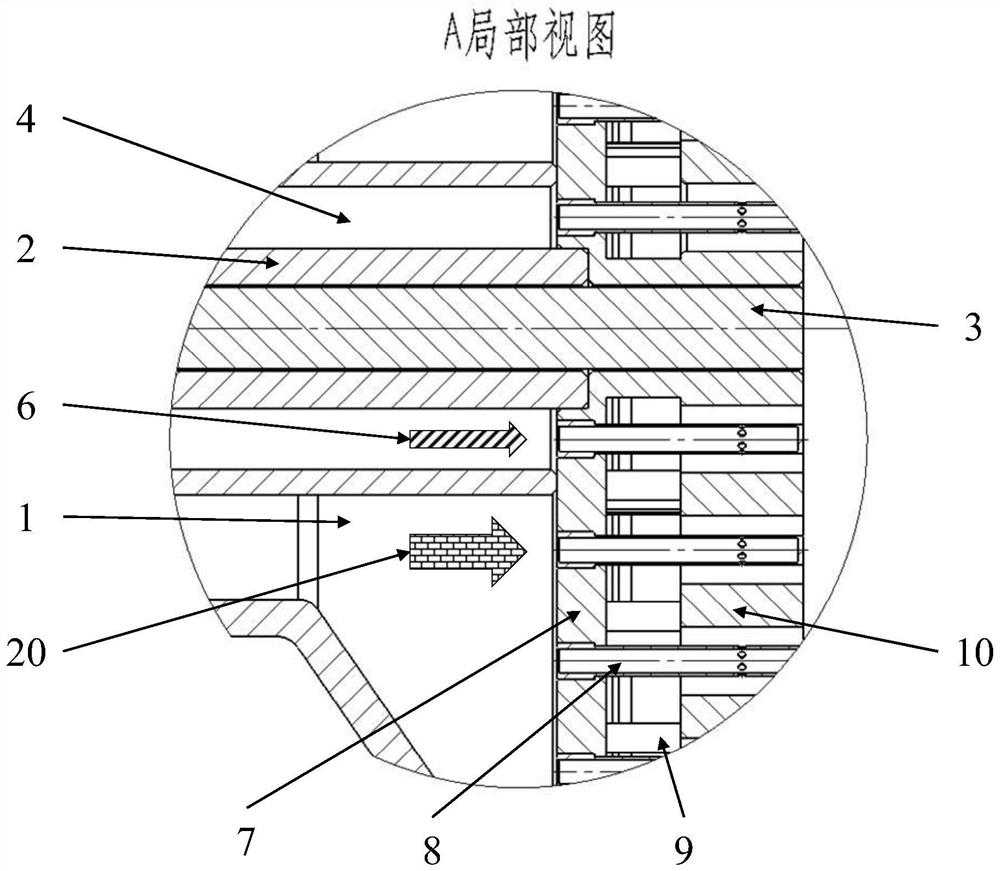

[0033] Such as Figure 1-Figure 8 As shown, a micro-scale premixed staged burner, the average temperature of the burner outlet 14 is 1500 ° C, the average temperature of the air 15 inlet is 300 ° C, including 60 micro-scale pre-mixed nozzles 8, the main fuel distribution chamber 1, and duty fuel Distribution cavity 4, main combustion air distribution cavity 9, burner top cover 2, nozzle distribution plate 7, air distribution plate 10, flame tube 11, casing 12 and electric igniter 3;

[0034] There is a through hole at the center of the burner top cover 2, and the duty fuel distribution chamber 4 and the main fuel distribution chamber 1 arranged coaxially with the through hole are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com