Fabricated wallboard steel bar hole aligning device with correcting function

A prefabricated, wall panel technology, applied in spraying devices, building material processing, construction, etc., can solve problems such as bumping, correction of reserved steel bars, and bending of reserved steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

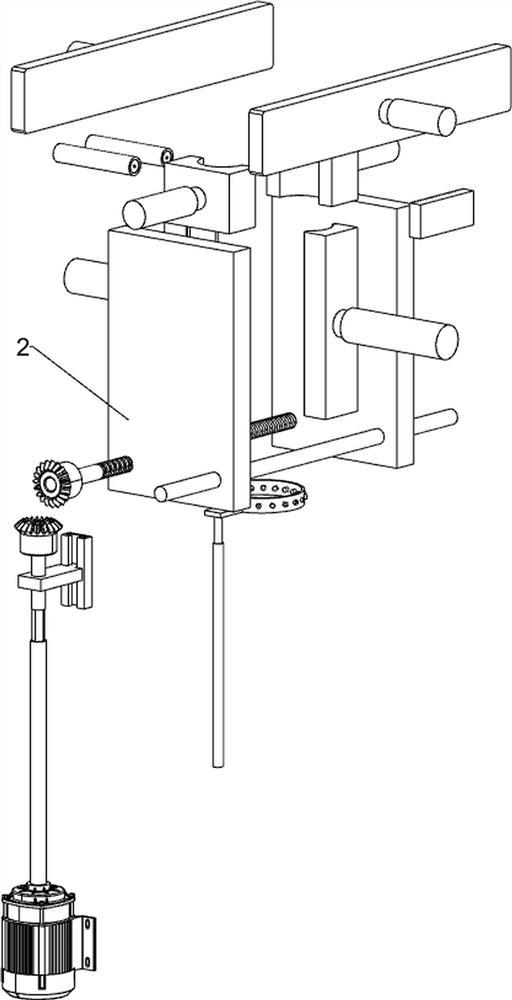

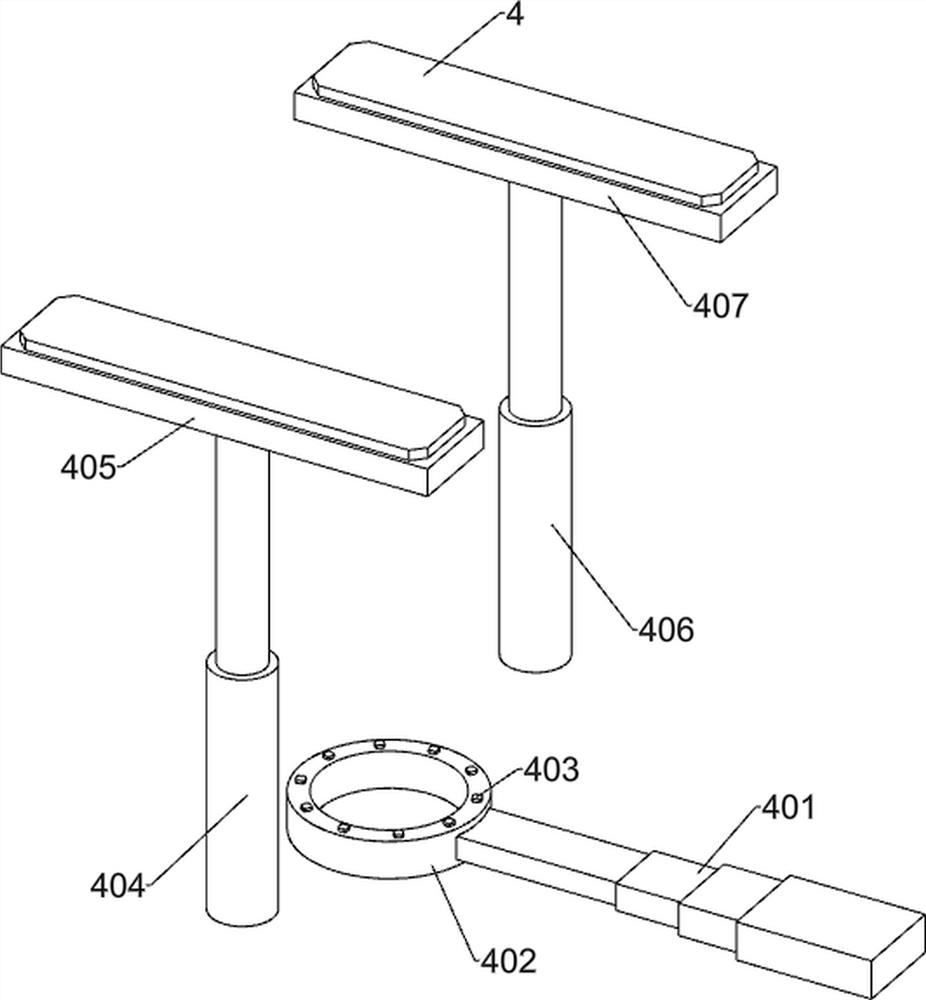

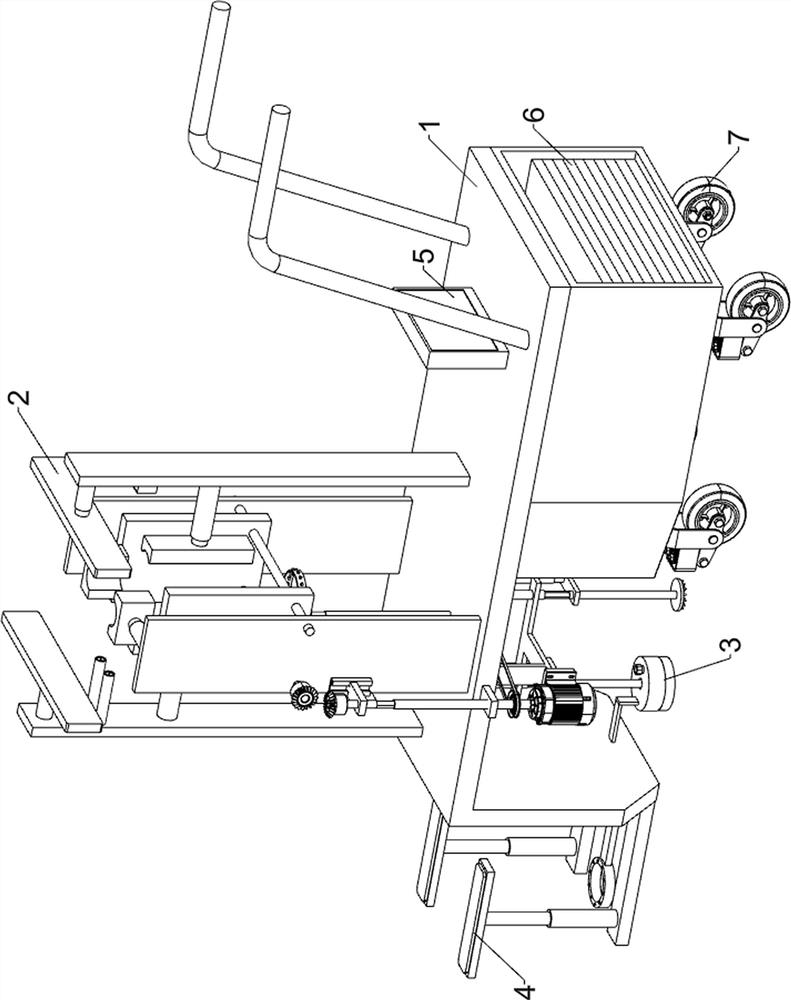

[0029] A device for aligning holes with steel bars in assembled wallboards with correction functions, such as Figure 1-8 As shown, it includes an underframe 1, a straightening assembly 2, an impurity removal assembly 3, a positioning assembly 4, a control panel 5, a counterweight 6 and a wheel 7; the underframe 1 is connected with the straightening assembly 2; the underframe 1 is connected with the The impurity removal component 3 is connected; the chassis 1 is connected with the positioning component 4; the chassis 1 is connected with the control panel 5; the chassis 1 is connected with the counterweight 6; the chassis 1 is connected with the wheel 7; the straightening component 2 is connected with the impurity removal assembly 3.

[0030] When preparing for work, use the crane to transport the assembled wall panel above the reserved hole on the ground, and make the assembled wall panel above the expected installation position, and then push the chassis 1 so that the wheel 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com