Steel structure conveying belt corridor

A conveyor belt and steel structure technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that workers are easily affected by noise, increase costs, and materials drop, so as to improve elasticity, reduce power loss, The effect of strengthening rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

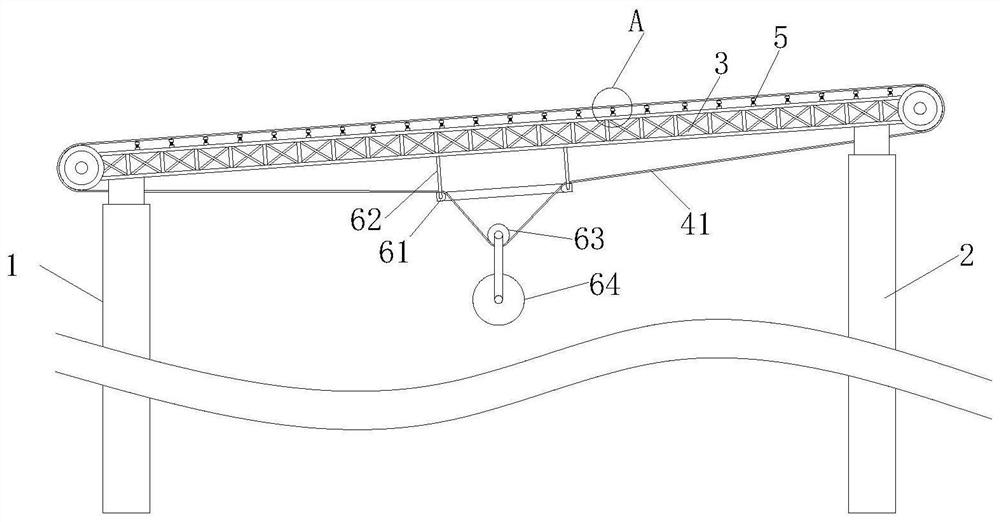

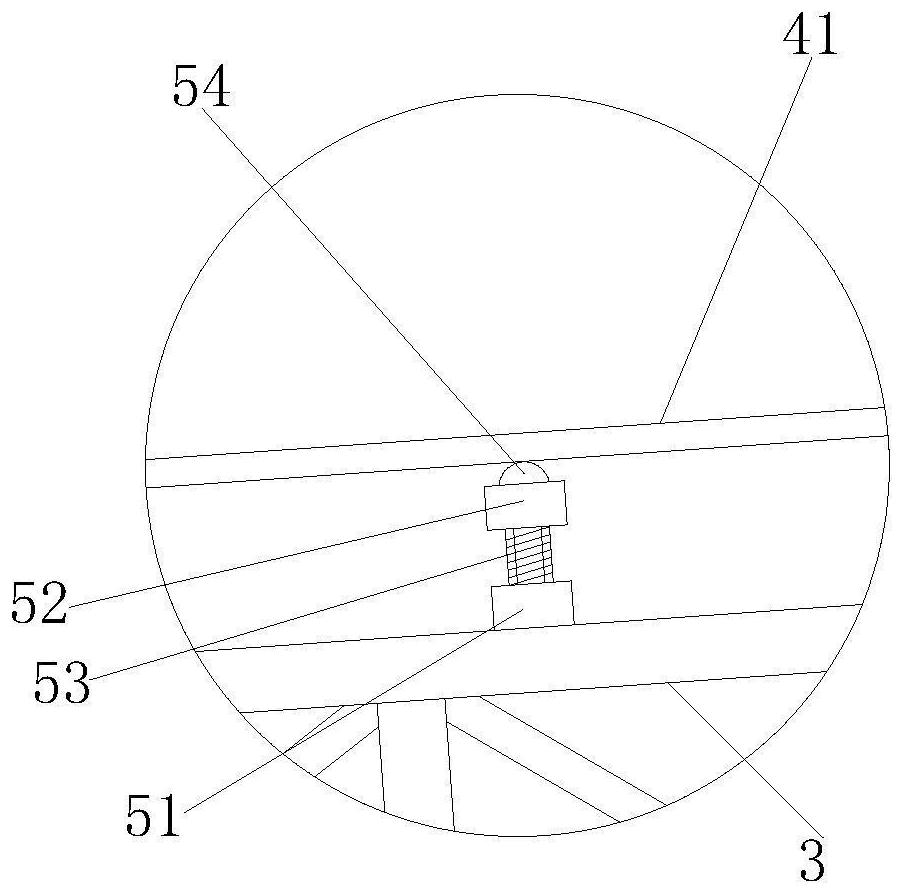

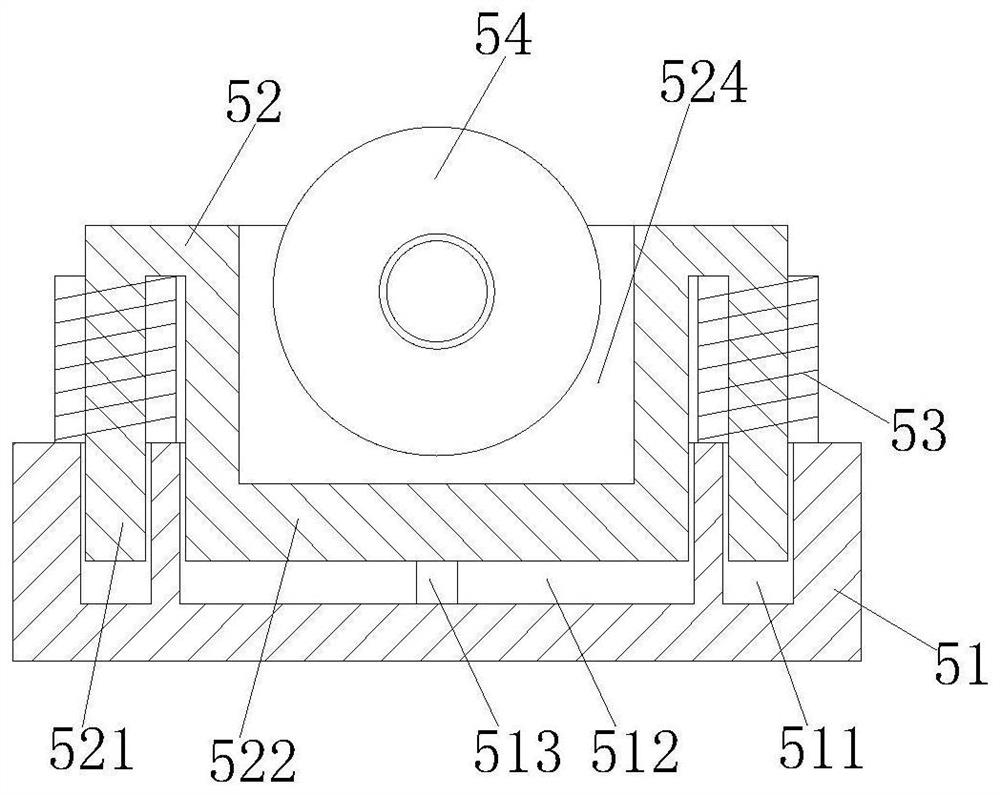

[0023] Such as Figure 1-Figure 4 As shown, a steel structure conveyor belt gallery described in this embodiment includes a belt gallery and a first bracket 1 and a second bracket 2 supporting both ends of the belt gallery; the belt gallery includes a steel structure main body 3, a transport mechanism and a tensioning mechanism. mechanism, the transportation mechanism includes a belt 41; it is characterized in that: the tensioning mechanism is set on the side of the steel structure main body 3 away from the material, so that the belt 41 is in a tensioned state, and the steel structure main body 3 and the side carrying the material Several elastic support mechanisms 5 are arranged between the belts 41, and the elastic support mechanisms 5 include: a fixed seat 51, an adjustment block 52, an elastic member 53 and a roller 54; the fixed seat 51 is fixedly connected with the steel structure main body 3, and the The elastic member 53 is arranged between the fixing seat 51 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com