A silicon block crushing device and its use method, a silicon block crushing method and its application method

A technology of crushing device and application method, which is applied in the direction of grain processing, etc., can solve the problems of silicon block surface pollution, silicon block metal pollution, affecting the quality of downstream single crystal products, etc., and achieve the effect of eliminating half-fracture phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

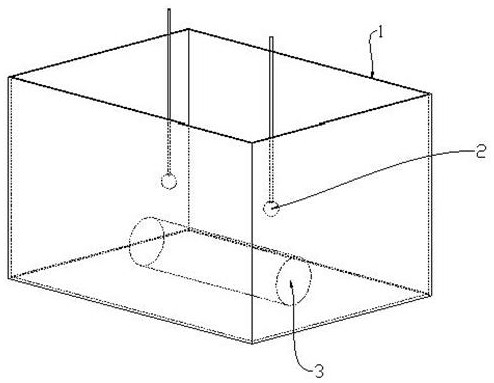

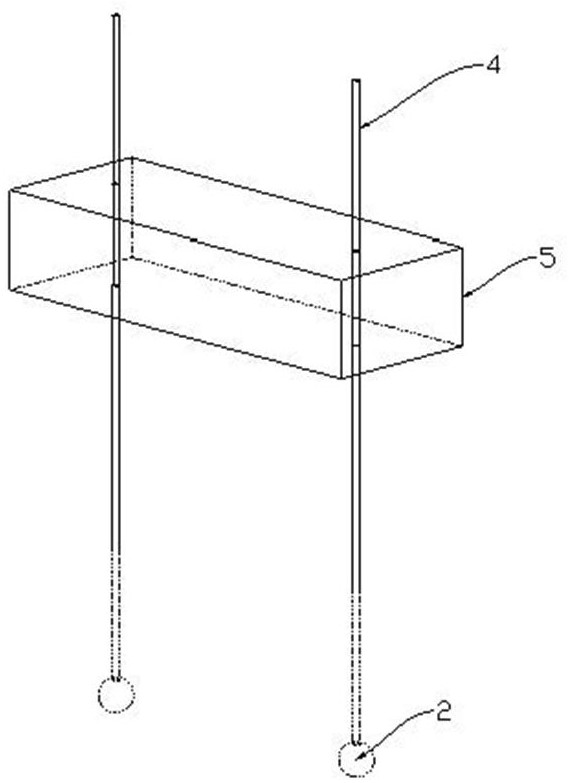

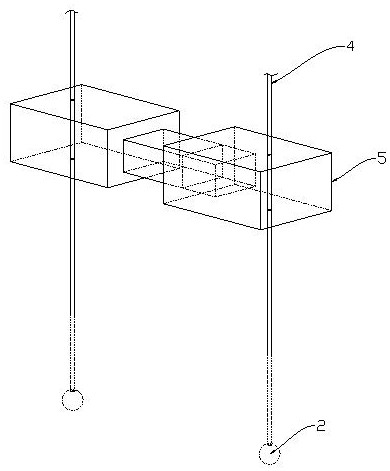

[0057] The value range of the above-mentioned resistivity ρ is easier to meet in the preparation of high-purity water, and the silicon block crushing device provided in the present invention can effectively avoid the pollution introduced by people or metal materials during the manual or mechanical crushing process. As far as the whole device is concerned, the two pulse electrodes 2 can be adjusted in various ways, and the wire 4 connected to the pulse electrode 2 or other related structures can be fixed through the fixing structure 5, so as to realize the suspension of the pulse electrode 2; Wherein, taking the fixing of the wire 4 as an example, the connection of the wire 4 and the fixed structure 5 and the adjustment of the length of the wire 4 relative to the fixed structure 5 are relatively easy to realize, and the adjustment of the suspension height can be quickly realized through the above adjustment. In order to realize the position adjustment of the two pulse electrodes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com