Electronic product leather rear cover capable of being thermally formed and production process of electronic product leather rear cover

A technology for electronic products and production processes, applied in the field of leather back covers of electronic products and their production processes, can solve the problems of curved edges and arc top stretch, texture and deformation, poor overall product quality, insufficient functionality and aesthetics, etc. problems, to achieve the effect of improving productivity, improving aesthetics, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0028] A production process for a thermoformable leather back cover of an electronic product, comprising the following steps:

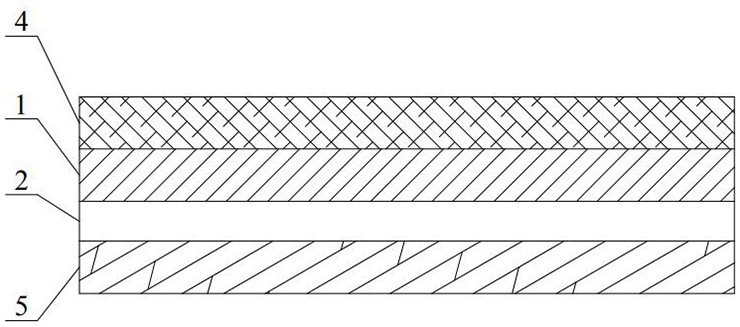

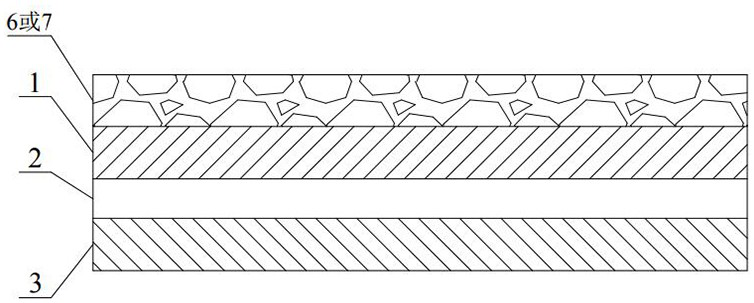

[0029] 1. Coating paint on embossed paper or embossed film with leather texture, adding thermochromic material or photochromic material or color paste or color paste of different colors and blending in the paint, and then drying and curing Shaping to obtain a leather layer 1 with embossed paper or embossed film.

[0030] 2. Coating acrylic glue or silica gel or pressure-sensitive adhesive on the surface of the leather layer 1 to form an adhesive layer 2 on the leather layer 1 .

[0031] 3. Paste a layer of release film 3 on the adhesive layer 2 (obtained as figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com