Side winding device and method of micro coil

A technology of miniature coil and winding device, which is applied in the direction of coil manufacturing, etc., can solve the problems of wire breaking, tying into a ball, and jamming, and achieves the effect of good protection and improved coil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

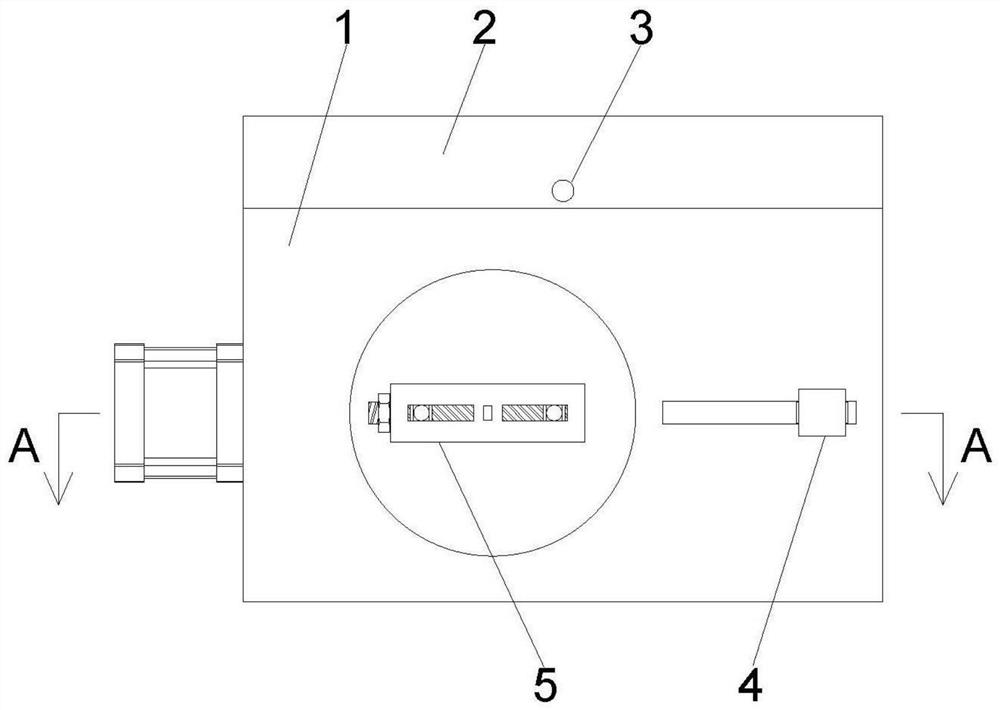

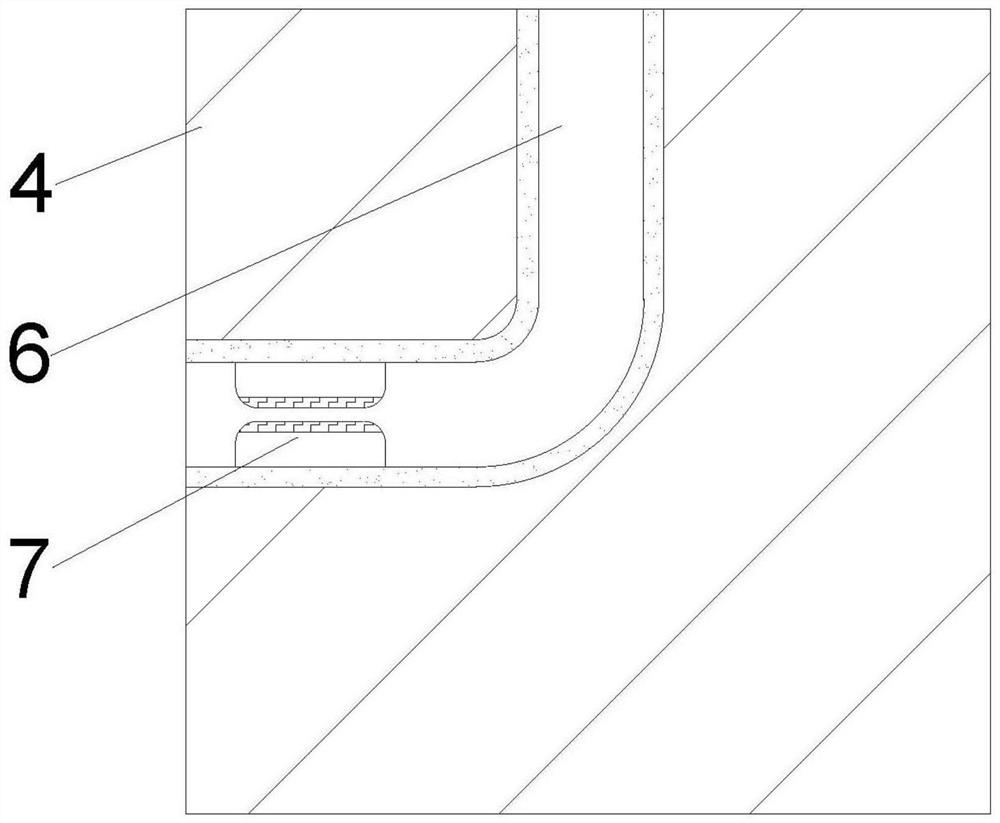

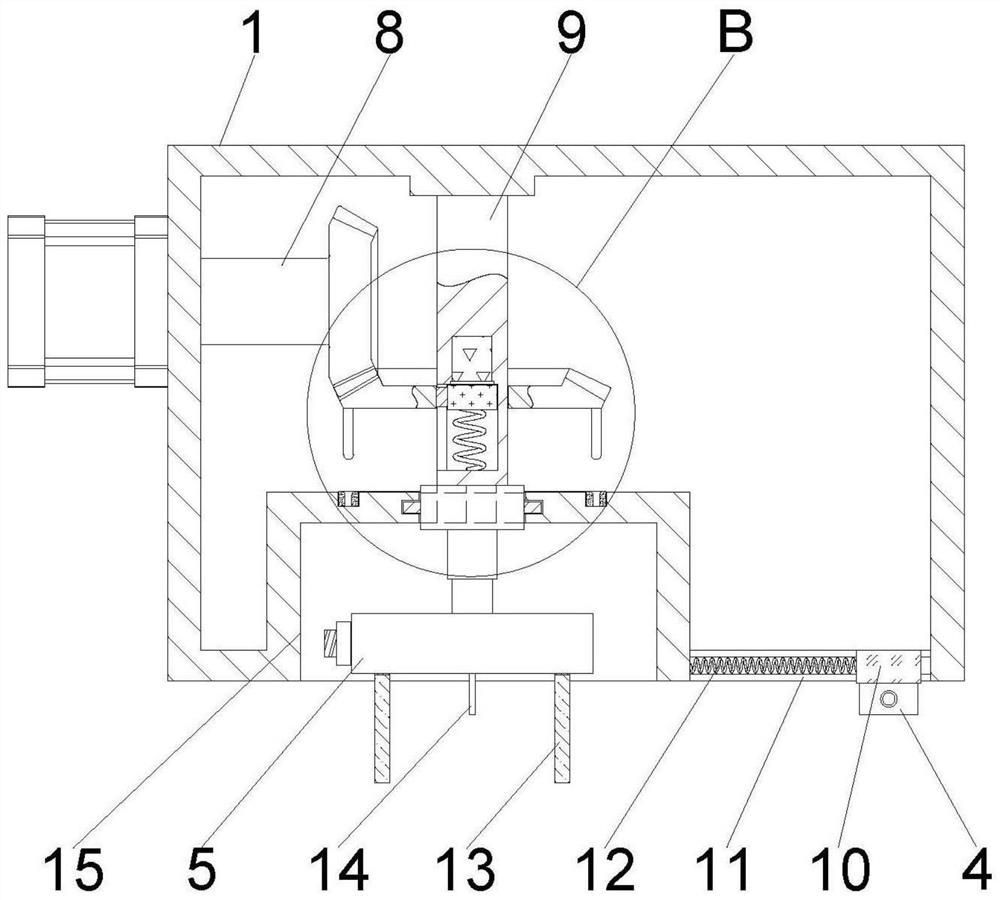

[0030] like figure 1 and image 3 In the described embodiment, a side-winding winding device for a microcoil includes a machine base 1, a placement plate 2 is arranged on the top surface of the machine base 1, and an outlet hole 3 is provided on the placement plate 2, and the machine base 1 A wire winding device and a wire clamp block 4 are arranged on the side, the wire winding device is connected to the frame 1 in rotation, the wire clamp block 4 and the frame 1 are slidably connected and placed on the side of the wire winding device, and the outlet hole 3 is located between the wire winding device and the frame 1. Between the wire clamping blocks 4, the inside of the base 1 is equipped with a driving shaft 8 and a driven shaft 9, the driven shaft 9 is fixed on the winding device and is perpendicular to the driving shaft 8, and a bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com