Underground sewer pipe clamping and fixing device with multiple fixing clamping points

A sewage pipeline, clamping and fixing technology, applied in the sewer pipeline system, water supply device, waterway system, etc., can solve the problems of wasting manpower, manual operation, labor intensity, and waste of construction time, so as to improve the degree of automation and improve the fixing effect , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

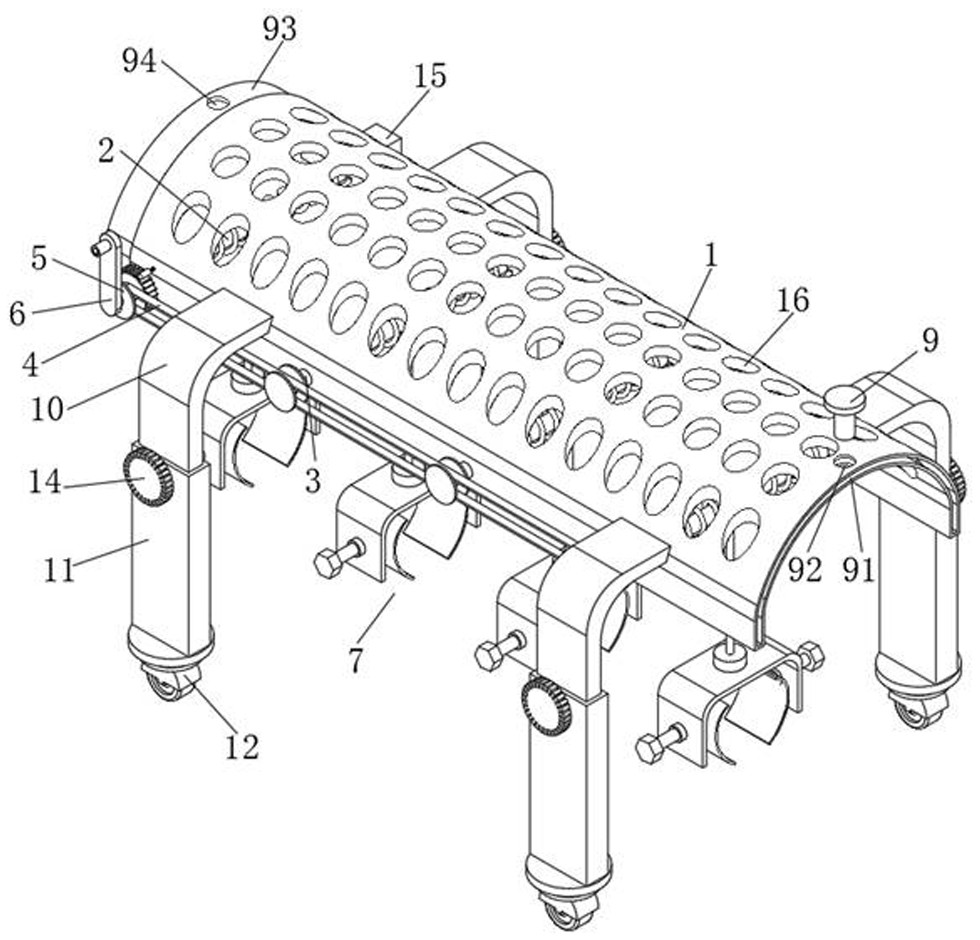

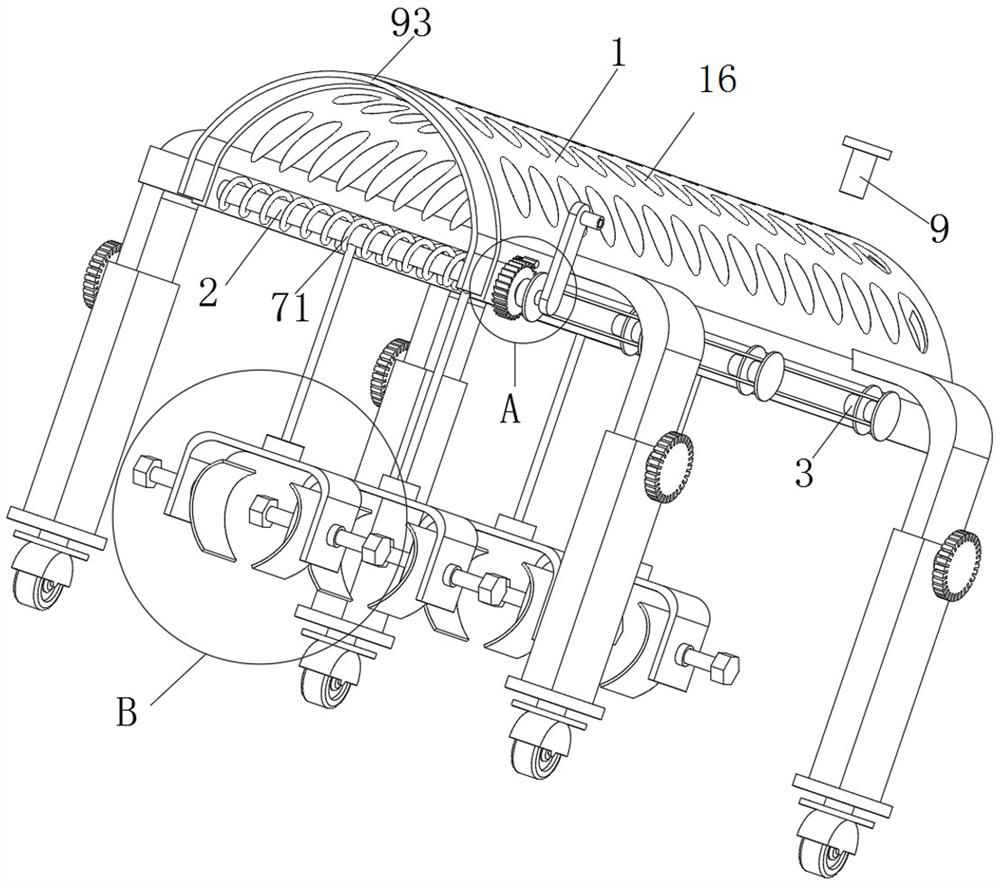

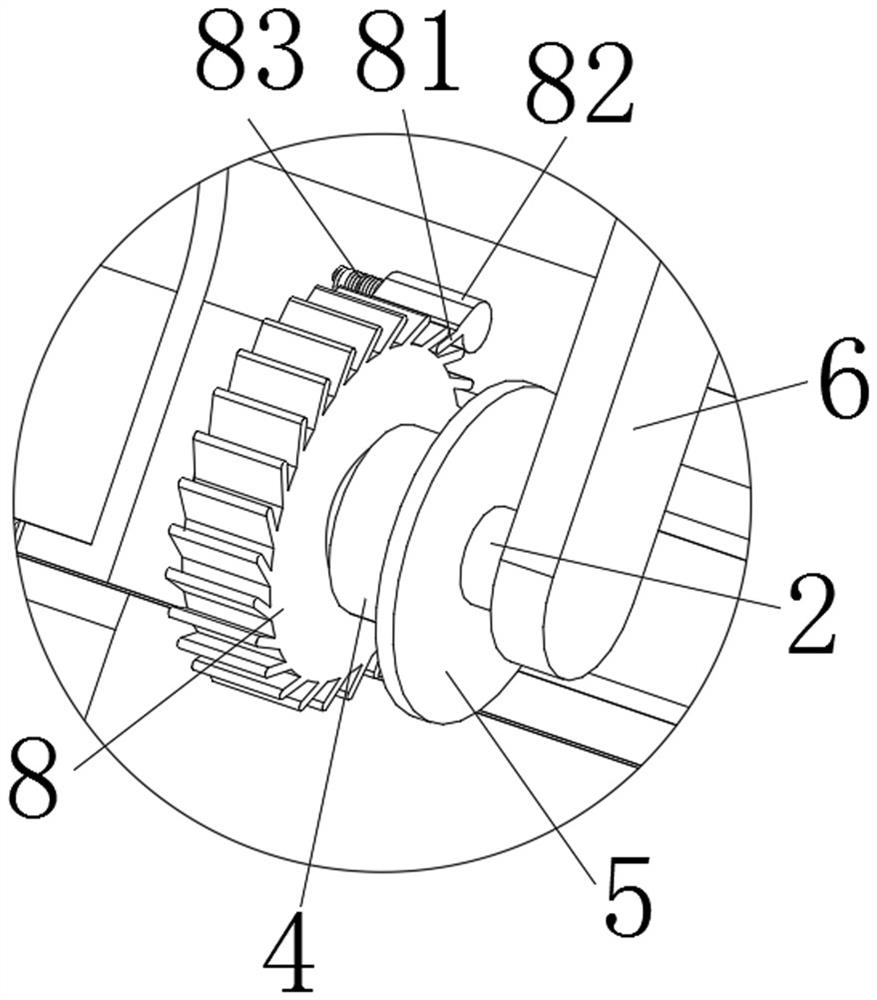

[0030] Such as Figure 1-6 As shown, the clamping and fixing device for underground sewer pipes with multiple fixed clamping points of the present invention includes an arc-shaped roof 1, and the front and rear inner walls of the arc-shaped roof 1 are rotatably connected with a main shaft 2 and a plurality of auxiliary shafts 3, and the main shaft 2 and multiple The front ends of each auxiliary shaft 3 all pass through the front inner wall of the arc top plate 1 and extend forward. Cables 71 are wound and fixed on the peripheral surfaces of the main shaft 2 and the auxiliary shafts 3 . The lower ends of the cables 71 are provided with clamping mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com