An electric automatic multi-station cartoning device

An electric automation, multi-station technology, applied in the direction of packaging, packaging machines, transportation and packaging, etc., can solve the problems of long intermittent time, fast transportation movement, limiting the moving efficiency of paper boxes, etc., to reduce manual operations The operation, the effect of improving the packing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

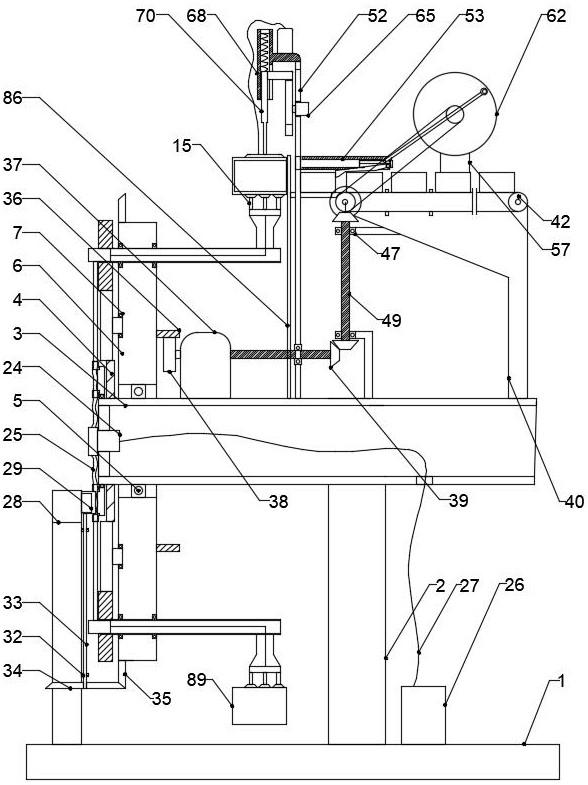

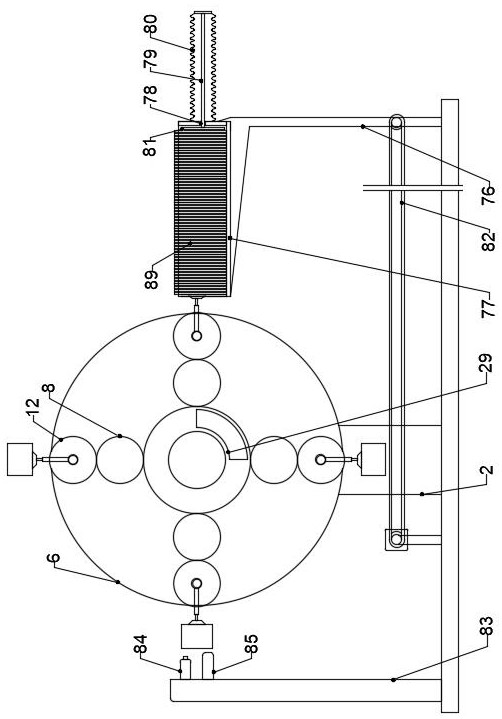

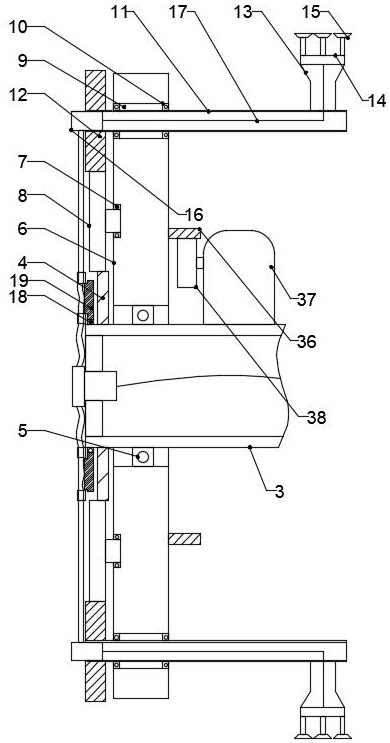

[0037] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-19 As shown, an electric automation multi-station boxing device comprises a rectangular base 1, the upper surface of the rectangular base 1 is provided with a multi-station rotating mechanism, one side of the multi-station rotating mechanism is provided with an intermittent feeding mechanism, and the upper end of the intermittent feeding mechanism is provided with There is a charging auxiliary mechanism;

[0038] The multi-station rotating mechanism includes a support column 2 installed on the upper surface of the rectangular base 1, a horizontal tube 3 is installed on the upper end of the support column 2, a fixed gear 4 is installed on one end of the horizontal tube 3, a ball bearing 5 is installed on one end of the horizontal tube 3, and a ball bearing 5 is installed on one end of the horizontal tube 3. The outer ring of the bearing-5 is equipped with a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com